34CrNiMo6 wind power main shaft forging forming method for low wind speed wind turbine set

A technology for wind power spindles and wind turbines, which is used in engine manufacturing, mechanical equipment, engine components, etc., can solve the problems of overheating of the small diameter end, easy overcooling of the small diameter end, and large size of the wind power spindle, so as to improve the mechanical performance and reduce the The effects of unbalanced tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

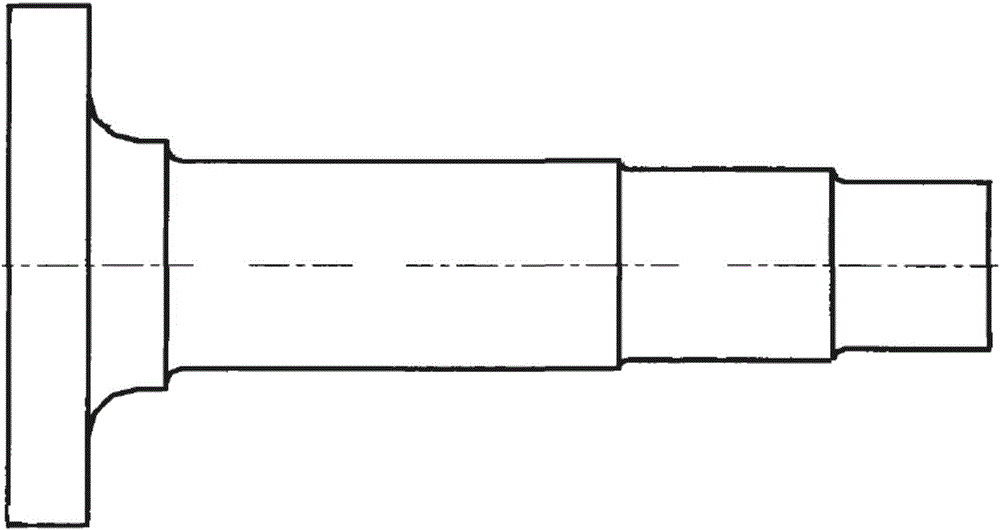

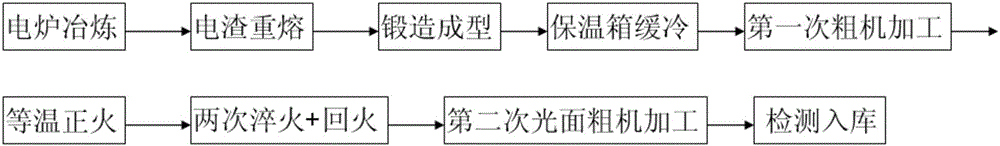

[0046] Such as Figure 1-2 Shown is a forging method for a 34CrNiMo6 wind power main shaft of a low wind speed wind turbine. The wind power main shaft includes a flange part and a variable-section shaft part.

[0047]The composition of the 34CrNiMo6 wind power main shaft material of the low wind speed wind turbine is controlled as follows: C0.30%~0.37%, Si 0.30%~0.60%, Mn 0.60%~1.00%, Cr 1.40%~1.70%, Ni 1.40%~1.70% , Mo 0.15%~0.35%, P<0.008%, S<0.005%, Cu<0.05%, As<0.005%, Al<0.005%, Sn<0.005%, Sb<0.005%, the rest is Fe and unavoidable Impurities.

[0048] The 34CrNiMo6 wind power spindle forging method of the low wind speed wind turbine specifically includes the following steps:

[0049] Step a, select steel ingot raw materials smelted by electric furnace + LF (outside furnace refining) + VD (vacuum degassing) + vacuum casting;

[0050] Step b, electroslag remelting the steel ingot raw material in step a;

[0051] Step c, pre-forging billet: heating the electroslag remelt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com