Cast silicon carbide composite material and preparation method thereof

A composite material and silicon carbide technology, applied in the field of composite materials, can solve the problems of poor erosion and wear resistance, long parts supply and maintenance cycle, easy to fall off, etc., achieve excellent wear resistance and chemical corrosion resistance, improve Safety, reliability and strong chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

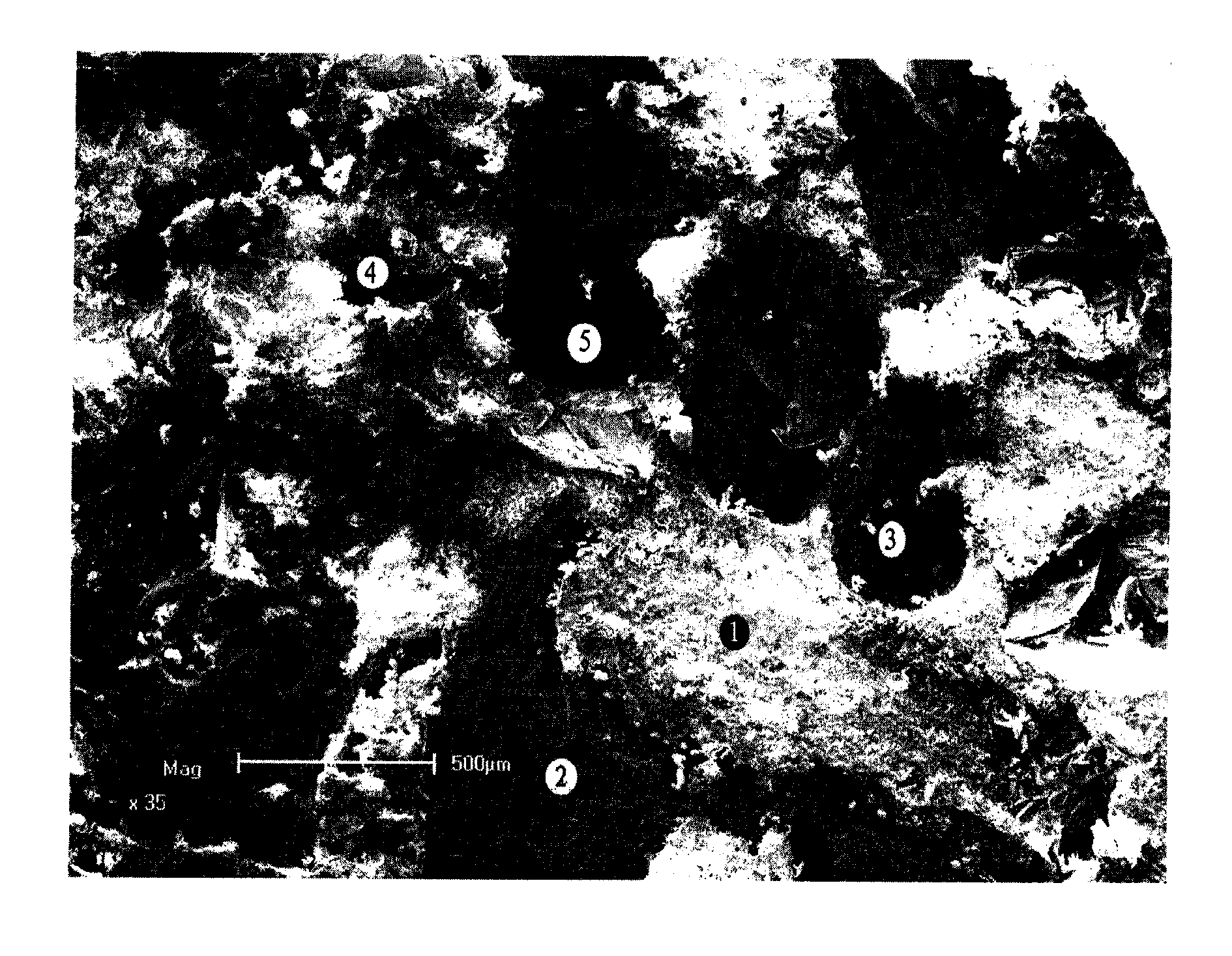

Image

Examples

Embodiment 1

[0062] The cast silicon carbide composite material contains the following components in parts by weight:

[0063] 60 parts of silicon carbide 0.5 parts of short glass fiber 1.5 parts of alumina powder

[0064] 0.8 parts of carbon fiber, 30 parts of acrylic resin

[0065] Also contain the additive of following parts by weight:

[0066] Reactive diluent butyl glycidyl ether: 3 parts

[0067] Accelerator DMP-30: 0.45 parts

[0068] Leveling agent Levelling 620: 0.09 parts

[0069] Modifier 651 polyamide: 0.9 parts

[0070] Coupling agent methoxysilane: 0.9 parts

[0071] Curing agent methyl tetrahydrophthalic anhydride: 19.5 parts

[0072] Toughening agent polysulfide rubber: 4.5 parts

[0073] Defoamer BX-841: 0.03 parts

[0074] The ratio of parts by weight of silicon carbide with different particle sizes is as follows:

[0075] 10-20 mesh 0.9 parts

[0076] 20-40 mesh 24 parts

[0077] 40-60 mesh 6 parts

[0078] 100-120 mesh 2.4 parts

[0079] The preparation m...

Embodiment 2

[0103] The cast silicon carbide composite material contains the following components in parts by weight:

[0104] 65 parts of silicon carbide 1.0 parts of short glass fiber 2.5 parts of alumina powder

[0105] 1.2 parts of carbon fiber, 20 parts each of bisphenol-A epoxy resin and bisphenol-F epoxy resin

[0106] Also contain the additive of following parts by weight:

[0107] Inactive diluent ethanol: 6 parts

[0108] Accelerator triethanolamine: 0.12 parts

[0109] Leveling agent BYK-333: 0.28 parts

[0110] Modifier silicon nitride powder: 2 parts

[0111] Coupling agent tetraisopropyl titanate: 2 parts

[0112] Curing agent methyl tetrahydrophthalic anhydride: 30 parts

[0113] Toughening agent polyurethane: 10 parts

[0114] Defoamer BX-841: 0.24 parts

[0115] The ratio of parts by weight of silicon carbide with different particle sizes is as follows:

[0116] 10-20 mesh 1.625 copies

[0117] 20-40 mesh 31.20 parts

[0118] 40-60 mesh 9.75 parts

[0119] 100-...

Embodiment 3

[0122] The cast silicon carbide composite material contains the following components in parts by weight:

[0123] 62 parts of silicon carbide 0.8 parts of short glass fiber 2.0 parts of alumina powder

[0124] 1.0 parts of carbon fiber, 20 parts of phenolic resin, 15 parts of polyurethane

[0125] Also contain the additive of following parts by weight:

[0126] Reactive diluent polypropylene glycol diglycidyl ether: 4.2 parts

[0127] Accelerator 2-methylimidazole: 0.47 parts, AC-2011 0.3 parts

[0128] Leveling agent BYK-333: 0.1 parts, Leveling 620 0.075 parts

[0129] Modifier 651 polyamide: 0.7 silicon nitride powder: 0.7 parts

[0130] Coupling agent chromium chloride methacrylate: 0.7, zirconium aluminate: 0.7 parts

[0131] Curing agent methyl tetrahydrophthalic anhydride: 24.5 parts

[0132] Toughening agent polyurethane: 3.5 parts, silicone modified polyether: 3.5 parts.

[0133] Defoamer BX-841: 0.105 parts

[0134] The ratio of parts by weight of silicon car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com