Steel ingot vacuum casting device

A technology of vacuum pouring and steel ingots, applied in ingot workshops, manufacturing tools, casting workshops, etc., can solve problems such as difficulties in production organization and operation, influence of molten steel yield, ingot shape restrictions, etc., to achieve stable operation and improve molten steel Yield rate, effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

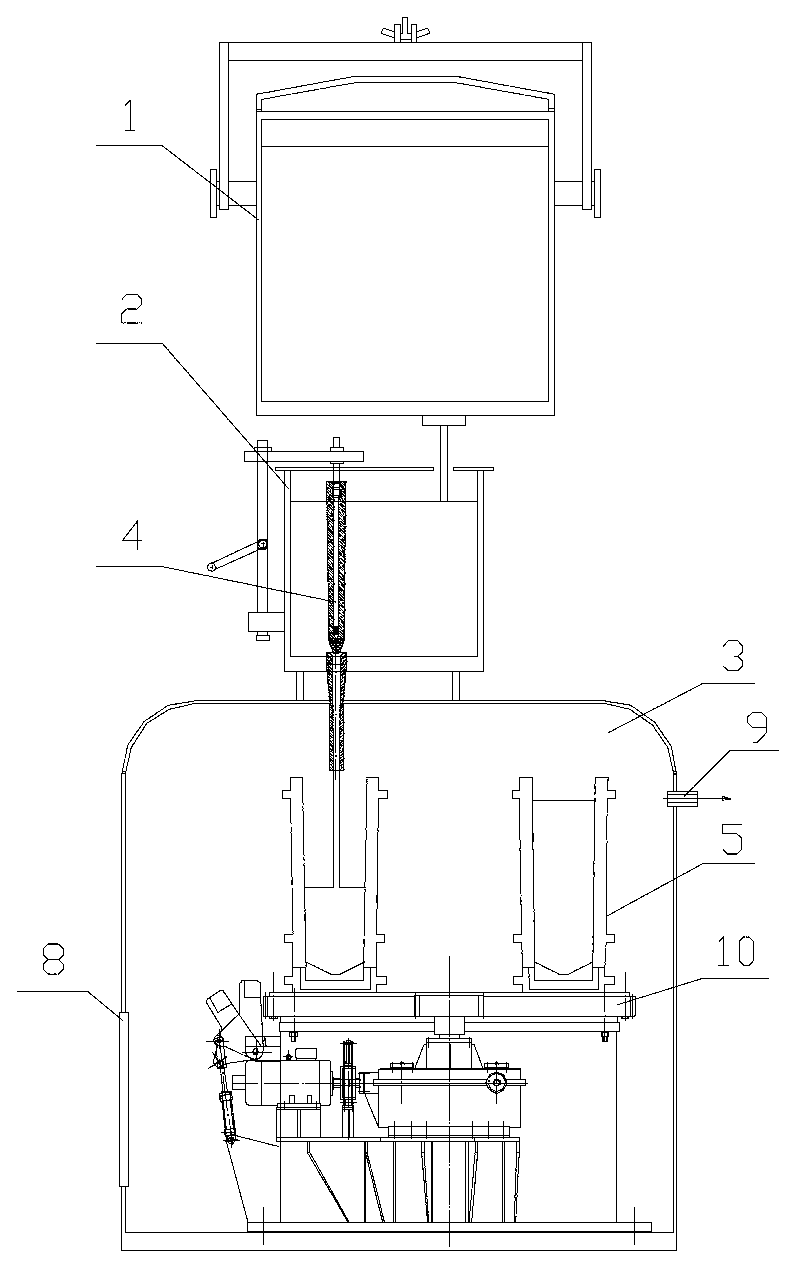

[0014] This embodiment is a vacuum pouring device for steel ingots, with a structure such as figure 1 As shown, it includes a refining bag 1, a tundish 2 arranged under the refining bag 1, and a vacuum tank 3 arranged under the tundish 2. The tundish 2 is connected to the vacuum tank 3 through a stopper rod 4, and multiple vacuum tanks are arranged in the vacuum tank 3. A steel ingot mold 5, a plurality of steel ingot molds 5 are arranged on a mobile trolley 6 and lined up, and when a certain steel ingot mold was positioned at the casting station, it was just below the stopper rod 4. The vacuum tank 3 is connected with a trolley chamber 7, the length of the trolley chamber 7 is greater than the length of the vacuum tank 3, and the height of the trolley chamber 7 is less than the height of the vacuum tank 3. An inspection hole 8 is provided on the trolley chamber 7 , and a gas discharge hole 9 is provided on the vacuum tank 3 .

[0015] When the present invention is specifical...

Embodiment 2

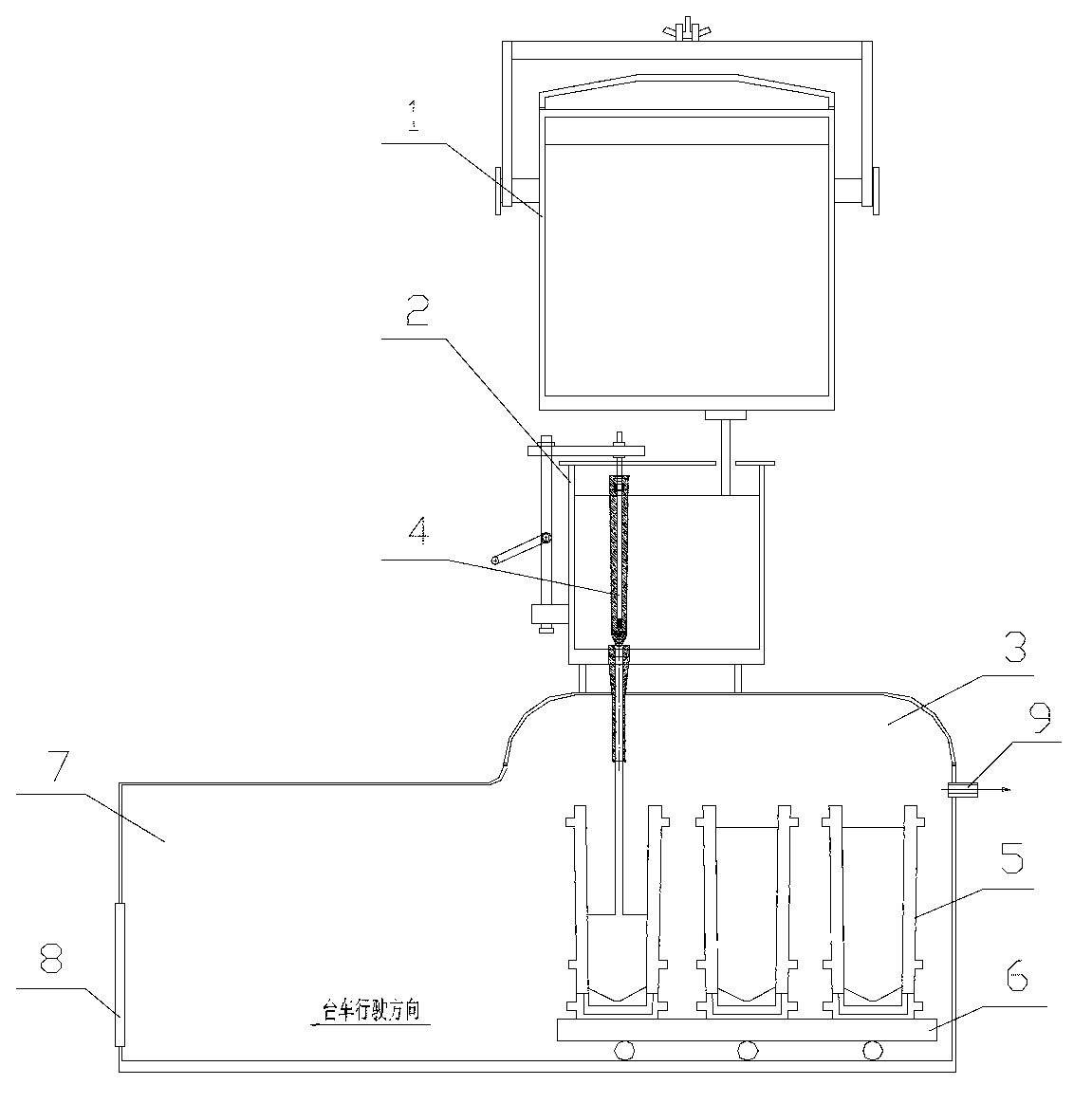

[0017] This embodiment is a vacuum pouring device for steel ingots, with a structure such as figure 2 As shown, it includes a refining bag 1, a tundish 2 arranged under the refining bag 1, and a vacuum tank 3 arranged under the tundish 2. The tundish 2 is connected to the vacuum tank 3 through a stopper rod 4, and multiple vacuum tanks are arranged in the vacuum tank 3. A steel ingot mold 5, a plurality of steel ingot molds 5 are arranged on a rotary platform 10, and are arranged circumferentially on the rotary platform 10. When a certain steel ingot mold is positioned at the pouring station, it is just below the stopper rod 4. An inspection hole 8 is provided on the vacuum tank 3 , and a gas discharge hole 9 is provided on the vacuum tank 3 .

[0018] When the present invention is specifically used, when the first steel ingot mold is located at the pouring station, it is just below the stopper rod 4. After the first steel ingot mold is poured, the rotation of the rotary plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com