High-strength high-plasticity high-yield-ratio magnesium-lithium alloy and preparation method and application thereof

A magnesium-lithium alloy, high yield-strength ratio technology, used in instruments, electrical digital data processing, digital data processing components and other directions, can solve the problem of strong plasticity and yield-strength ratio, short process flow, and low absolute strength of magnesium-lithium alloys and other problems to achieve the effect of improving tensile strength and high temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

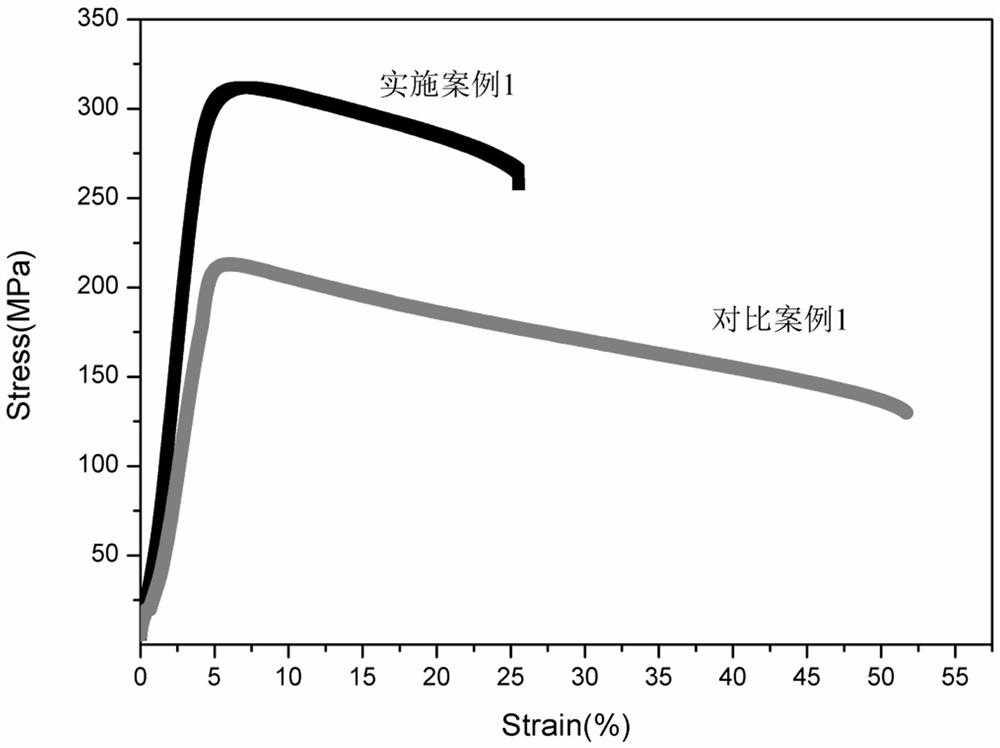

Embodiment 1

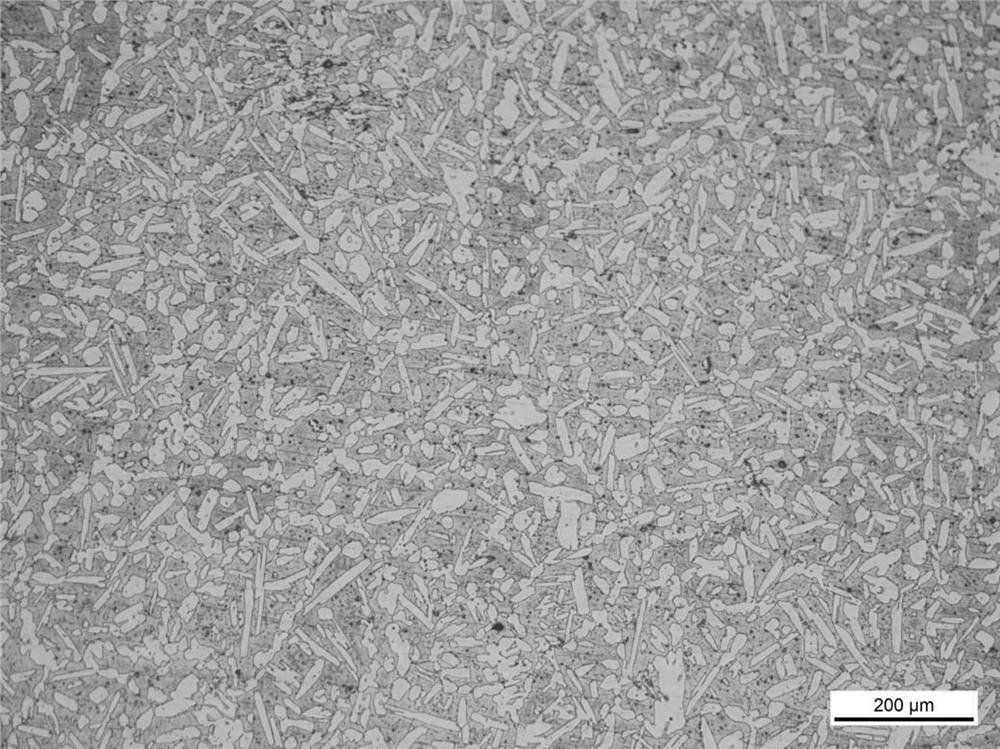

[0034]A high-strength, high-plasticity, high-yield ratio magnesium-lithium alloy, composed of the following components in mass percentage: Li 8%, Al 3%, Zn 1.5%, Y 0.5%, Sr 0.1%, AlTiC (grain refiner) 0.1%, the impurity elements Na and K are less than 0.001%, the total amount of Fe, Ni, Si, etc. is less than 0.05%, and the balance is Mg.

[0035] The preparation method of the high-strength, high-plastic and high-yield ratio magnesium-lithium alloy includes two stages of vacuum melting and casting, deformation and heat treatment, and the specific steps are as follows:

[0036] (1) Vacuum smelting and casting: batching is carried out according to the above-mentioned ratio of magnesium-lithium alloy elements. After batching, put it in a vacuum induction furnace to vacuumize and fill it with Ar to 500Pa, then raise the temperature to 750°C until it melts, and refine it with argon for 5 minutes. , keep it warm for 20 minutes and then cool down to 700°C, filter it through foam ceram...

Embodiment 2

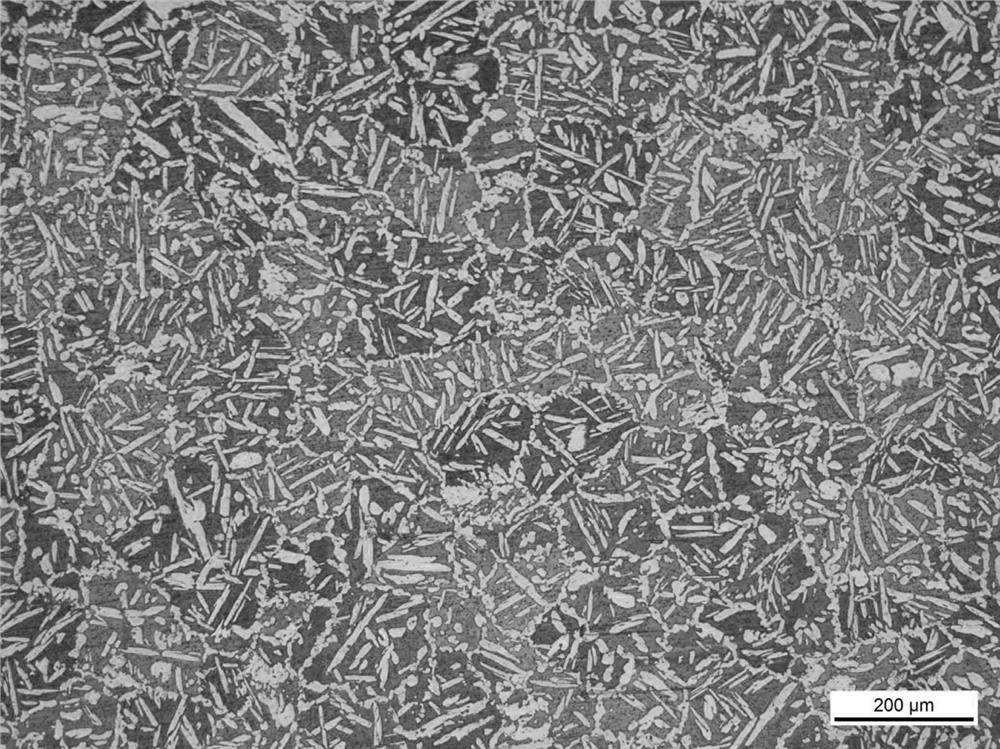

[0041] A high-strength, high-plasticity, high-yield ratio magnesium-lithium alloy consists of the following components by mass percentage: Li 9%, Al 3.5%, Zn 3%, Y 1%, Ca+Sr 0.2%, AlTiC (fine grain chemical agent) 0.1%, the impurity elements Na and K are less than 0.001%, the total amount of Fe, Ni, Si, etc. is less than 0.05%, and the balance is Mg.

[0042] The preparation method of the high-strength, high-plastic and high-yield ratio magnesium-lithium alloy includes two stages of vacuum melting and casting, deformation and heat treatment, and the specific steps are as follows:

[0043] (1) Vacuum melting and casting: according to the above-mentioned ratio of magnesium-lithium alloy elements, the ingredients are placed in a vacuum induction furnace, filled with Ar to 500Pa after vacuuming, and then heated to 800°C until melting, followed by argon refining for 5 minutes. Keep it warm for 20 minutes, then cool down to 720°C, filter it through foam ceramics, and cast it. After ...

Embodiment 3

[0047] A high-strength, high-plasticity, high-yield ratio magnesium-lithium alloy consists of the following components by mass percentage: Li 8.5%, Al 3.5%, Zn 3%, Nd 1.5%, Ca+Sr 0.3%, AlTiC (fine grain chemical agent) 0.1%, the impurity elements Na and K are less than 0.001%, the total amount of Fe, Ni, Si, etc. is less than 0.05%, and the balance is Mg.

[0048] The preparation method of the high-strength, high-plastic and high-yield ratio magnesium-lithium alloy includes two stages of vacuum melting and casting, deformation and heat treatment, and the specific steps are as follows:

[0049] (1) Vacuum melting and casting: according to the above-mentioned ratio of magnesium-lithium alloy elements, the ingredients are placed in a vacuum induction furnace, filled with Ar to 500Pa after vacuuming, and then heated to 800°C until melting, followed by argon refining for 5 minutes. Let it stand for 30 minutes and then cool down to 720°C. After being filtered by foam ceramics, it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com