High-specific-strength Ti-Al-Nb-Zr-Ta refractory high-entropy alloy

A ti-al-nb-zr-ta, high-entropy alloy technology, applied in the field of high specific strength Ti-Al-Nb-Zr-Ta refractory high-entropy alloys, can solve poor room temperature plasticity, refractory high-entropy alloys Problems such as high density and high production cost can achieve the effect of improving alloy strength, excellent comprehensive performance of strength and plasticity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

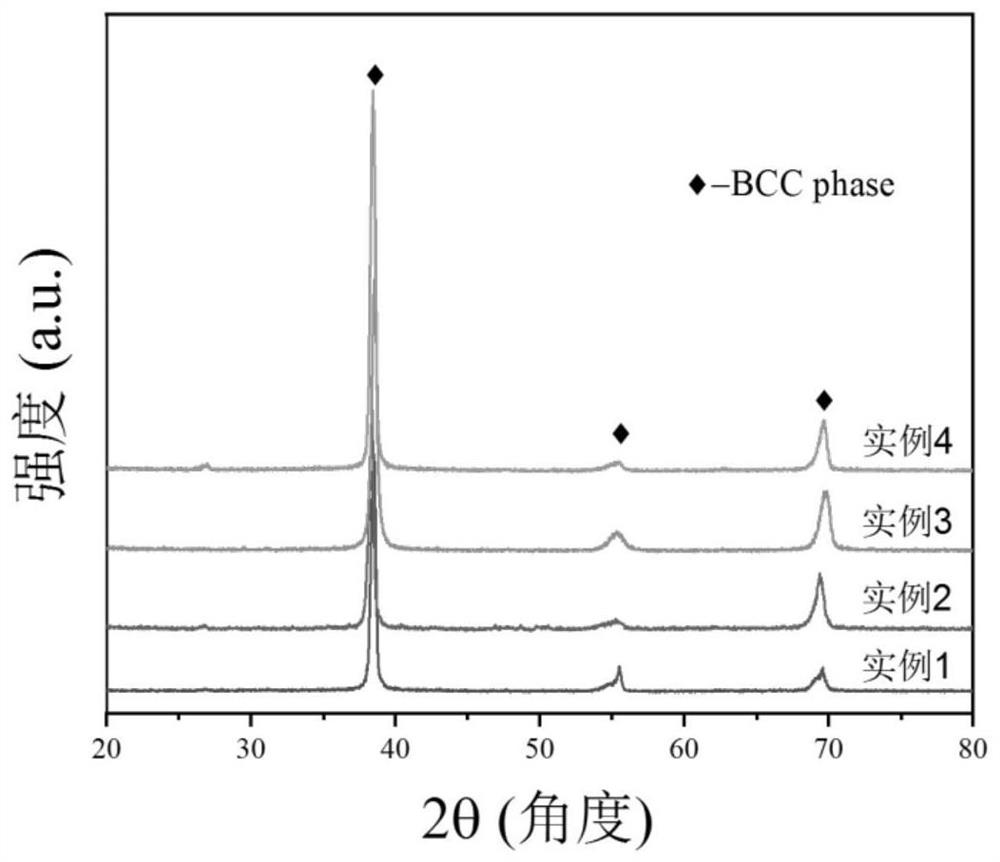

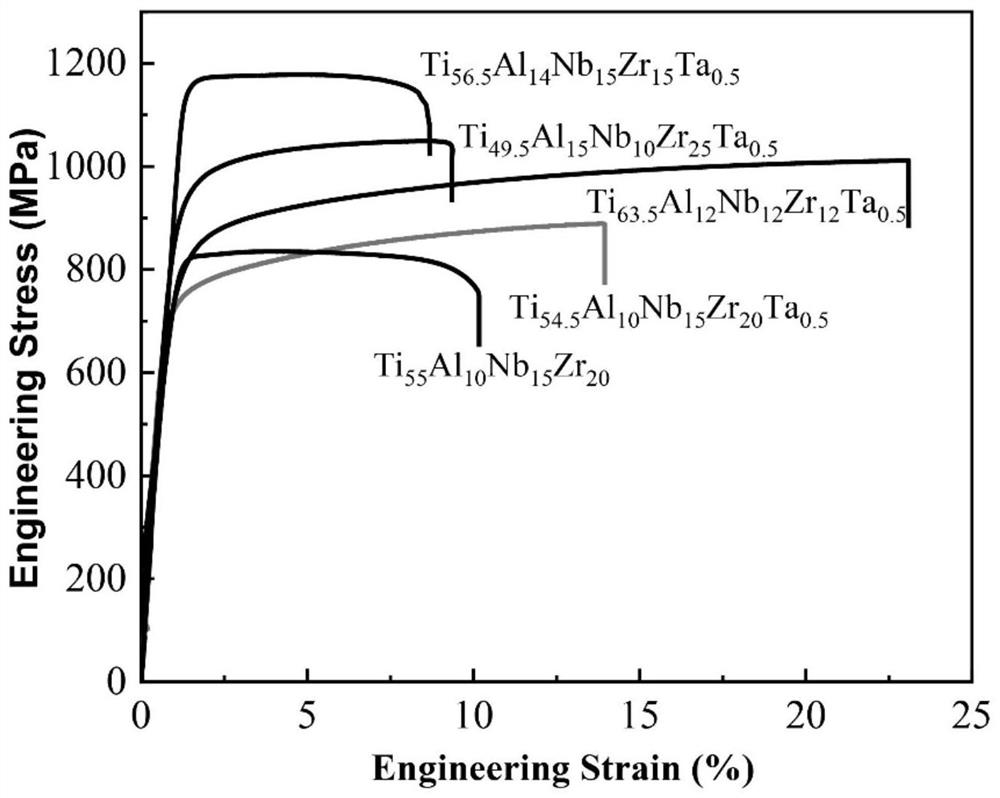

[0044] A Ti-Al-Nd-Zr-Ta five-element refractory high-entropy alloy whose alloy expression is Ti 63.5 Al 12 Nb 12 Zr 12 Ta 0.5 , its theoretical density is 5.088g / cm 3 , as a more detailed example, its preparation method and related tests include the following steps:

[0045] (1) Ingredients: select titanium with a purity of 99.5wt%, aluminum with a purity of 99.9wt%, niobium with a purity of 99.9wt%, zirconium with a purity of 99.9wt% and tantalum with a purity of 99.9wt%, and proceed according to the alloy expression For ingredients, before weighing the raw materials, first remove the oxide film on the surface of the raw materials with a wire brush or a grinder, then put the raw materials into a beaker filled with absolute ethanol and ultrasonically clean them for 100 seconds, and then completely dry them with a hair dryer. An electronic balance with an accuracy of 0.001g was used to accurately weigh the mass of each component (the error requirement was within ±0.005g). ...

Embodiment 2

[0049] A kind of Ti-Al-Nd-Zr-Ta quinary high entropy alloy, its alloy expression is Ti 56.5 Al 14 Nb 14 Zr 15 Ta 0.5 , its theoretical density is 5.196g / cm3, as a more detailed example, its preparation method and related tests include the following steps:

[0050] (1) Ingredients: select titanium with a purity of 99.5wt%, aluminum with a purity of 99.9wt%, niobium with a purity of 99.9wt%, zirconium with a purity of 99.9wt% and tantalum with a purity of 99.9wt%, and proceed according to the alloy expression For ingredients, before weighing the raw materials, first remove the oxide film on the surface of the raw materials with a wire brush or a grinder, then put the raw materials into a beaker filled with absolute ethanol and ultrasonically clean them for 100 seconds, and then completely dry them with a hair dryer. An electronic balance with an accuracy of 0.001g was used to accurately weigh the mass of each component (the error requirement was within ±0.005g).

[0051] (2...

Embodiment 3

[0054] A kind of Ti-Al-Nd-Zr-Ta quinary high entropy alloy, its alloy expression is Ti 49.5 Al 15 Nb 10 Zr 25 Ta 0.5 , its theoretical density is 5.211g / cm3, as a more detailed example, its preparation method and related tests include the following steps:

[0055] (1) Ingredients: select titanium with a purity of 99.5wt%, aluminum with a purity of 99.9wt%, niobium with a purity of 99.9wt%, zirconium with a purity of 99.9wt% and tantalum with a purity of 99.9wt%, and proceed according to the alloy expression For ingredients, before weighing the raw materials, first remove the oxide film on the surface of the raw materials with a wire brush or a grinder, then put the raw materials into a beaker filled with absolute ethanol and ultrasonically clean them for 100 seconds, and then completely dry them with a hair dryer. An electronic balance with an accuracy of 0.001g was used to accurately weigh the mass of each component (the error requirement was within ±0.005g).

[0056] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com