Casting magnesium alloy and preparation method thereof

A technology for casting magnesium alloys and alloy liquids, which is applied in the field of magnesium alloys, can solve problems such as poor plastic forming ability, and achieve good plasticity, cost reduction, and good solid solution strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention provides a method for preparing a cast magnesium alloy described in the above technical solution, comprising:

[0061] Mixing and melting magnesium source, zinc source, zirconium source and rare earth source to obtain alloy liquid;

[0062] The alloy liquid is cast to obtain a cast magnesium alloy.

[0063] Before mixing the magnesium source, zinc source, zirconium source and rare earth source, it is preferable to preheat to 200-250°C after removing the scale on the surface.

[0064] In the present invention, the mixing method is preferably:

[0065]The magnesium source is firstly added and after the magnesium source is melted, the zinc source and the rare earth source are sequentially added, and finally the zirconium source is added to obtain molten metal.

[0066] In the present invention, the crucible is preferably preheated to 500-600°C and the temperature is raised to 730-740°C after adding the magnesium source; more preferably, the crucible...

Embodiment 1

[0090] The magnesium source, the zinc source, the zirconium source and the ytterbium source are proportioned according to the mass ratio of each component, and the oxide skin on the surface of each raw material is removed, and each raw material is preheated to 200°C.

[0091] Preheat the crucible to 550°C, add magnesium source, raise the furnace temperature to 730°C, and feed SF with a volume ratio of 1:200 6 and CO 2 mixed gas as a shielding gas.

[0092] After the magnesium source is completely melted, add the above-mentioned zinc source and ytterbium source preheated to 200°C, and stir evenly.

[0093] After the above-mentioned stirring is completed, the temperature of the furnace is raised to 780° C. and the above-mentioned zirconium source preheated to 200° C. is added, and stirred evenly to obtain molten metal.

[0094] The molten metal is cooled to 740°C, and argon gas is introduced into it for 30 seconds to remove hydrogen.

[0095] Add No. 6 flux to the metal liqui...

Embodiment 2

[0100] The magnesium source, the zinc source, the zirconium source and the ytterbium source are proportioned according to the mass ratio of each component, and the oxide skin on the surface of each raw material is removed, and each raw material is preheated to 300°C.

[0101] Preheat the crucible to 550°C, add magnesium source, raise the furnace temperature to 740°C, and feed SF with a volume ratio of 1:200 6 and CO 2 mixed gas as a shielding gas.

[0102] After the magnesium source is completely melted, add the above-mentioned zinc source and ytterbium source preheated to 300°C, and stir evenly.

[0103] After the above-mentioned stirring is completed, the temperature of the furnace is raised to 780° C. and the above-mentioned zirconium source preheated to 300° C. is added, and stirred evenly to obtain molten metal.

[0104] The molten metal is cooled to 750°C, and argon gas is introduced into it for 30 seconds to remove hydrogen.

[0105] Add No. 6 flux to the molten meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

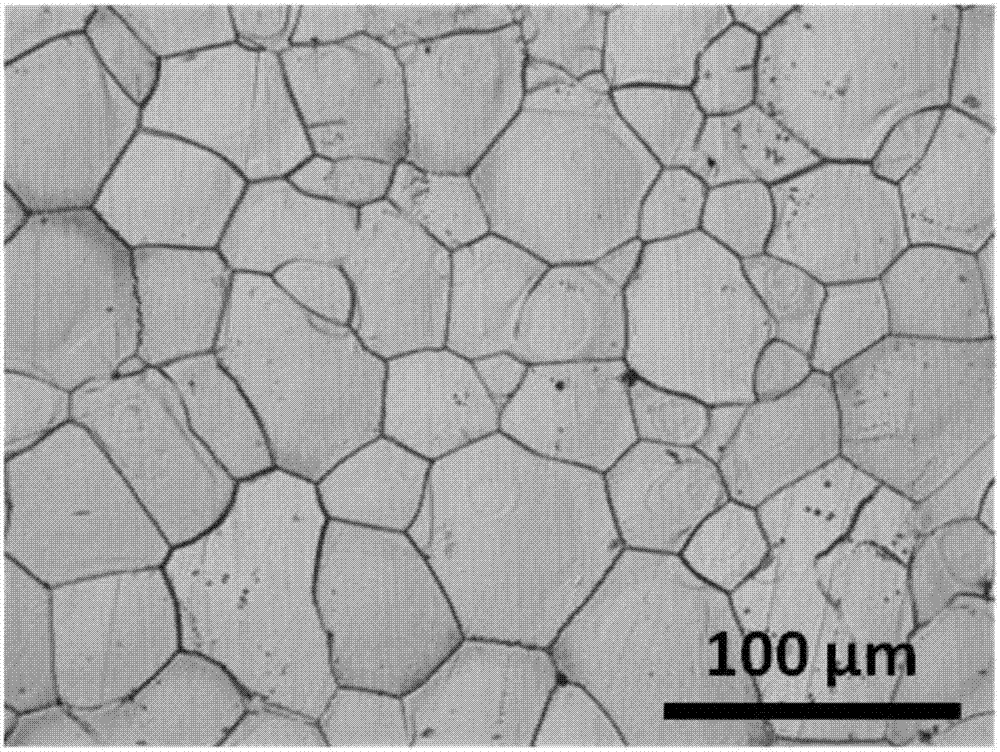

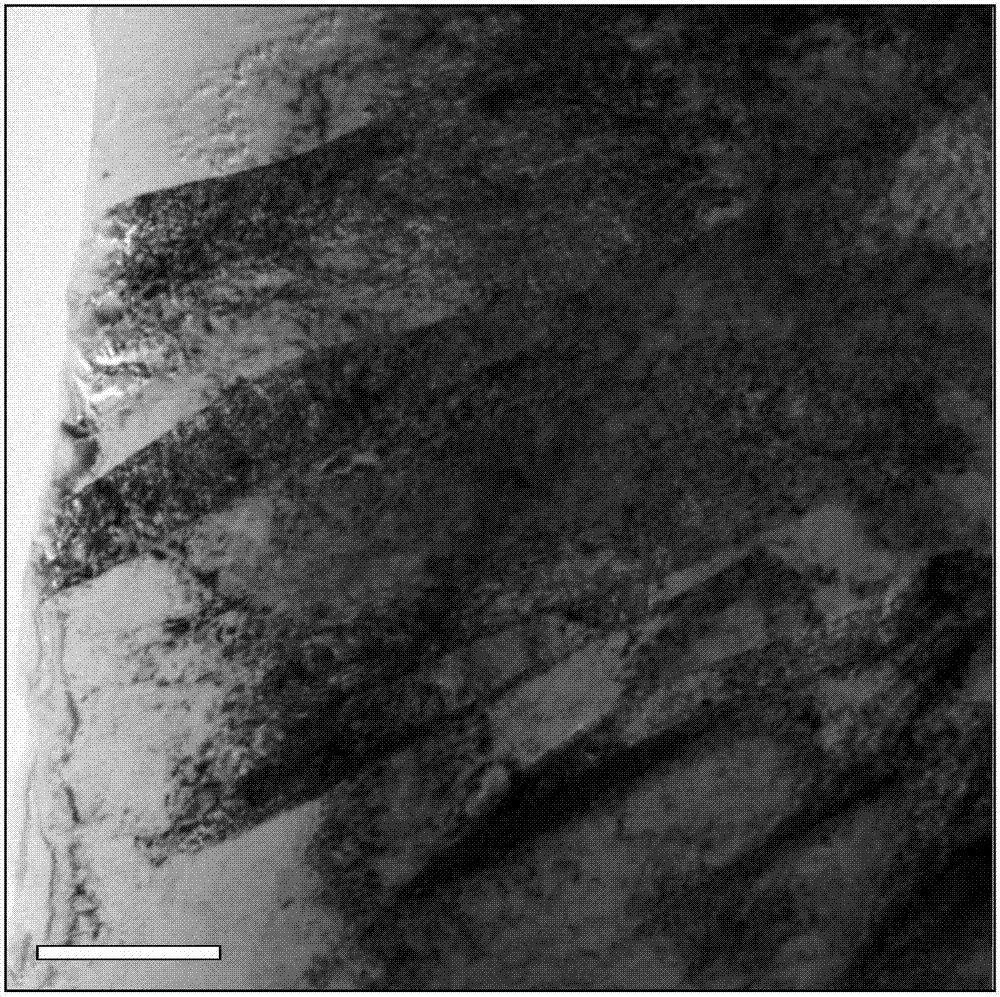

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com