Isolation gas channel formation mould for vacuum casting transformer coil and its prepn. method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The vacuum cast transformer coil isolation airway forming mold of the present invention is characterized in that it is composed of an arc-shaped profile with a closed cavity.

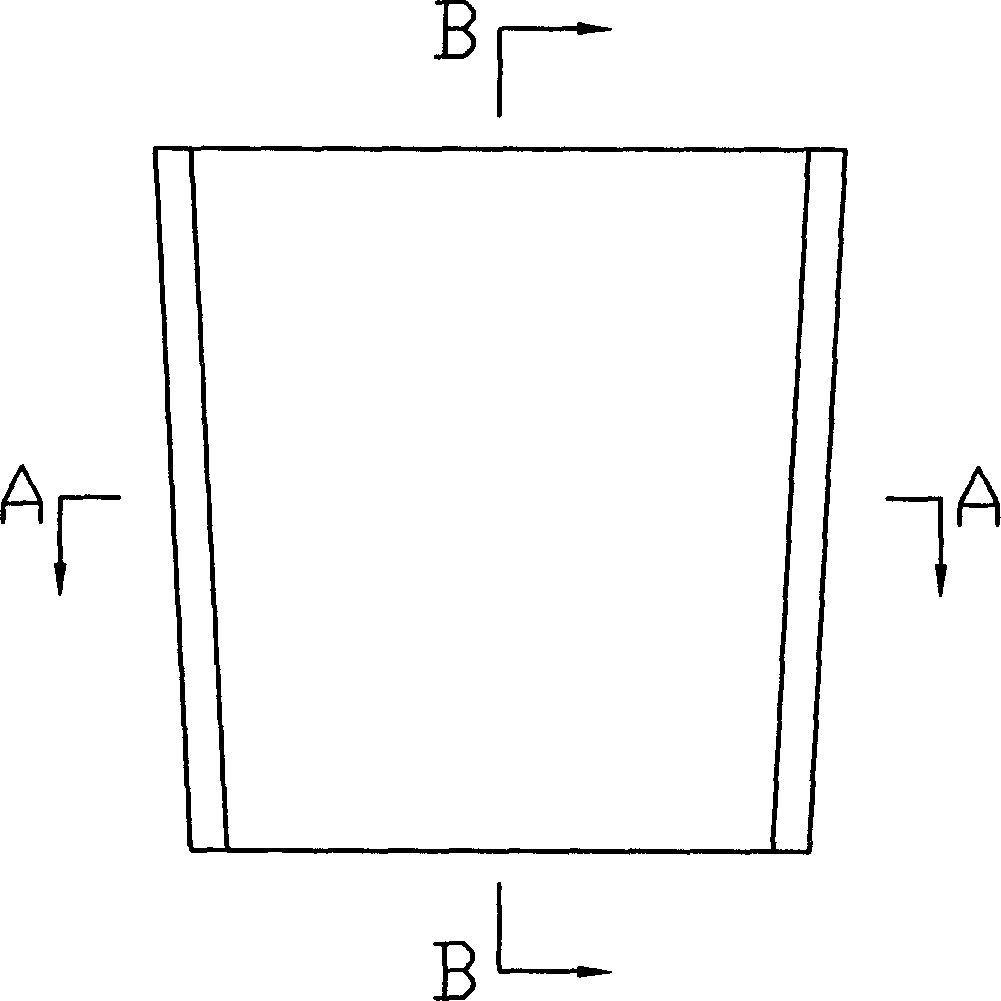

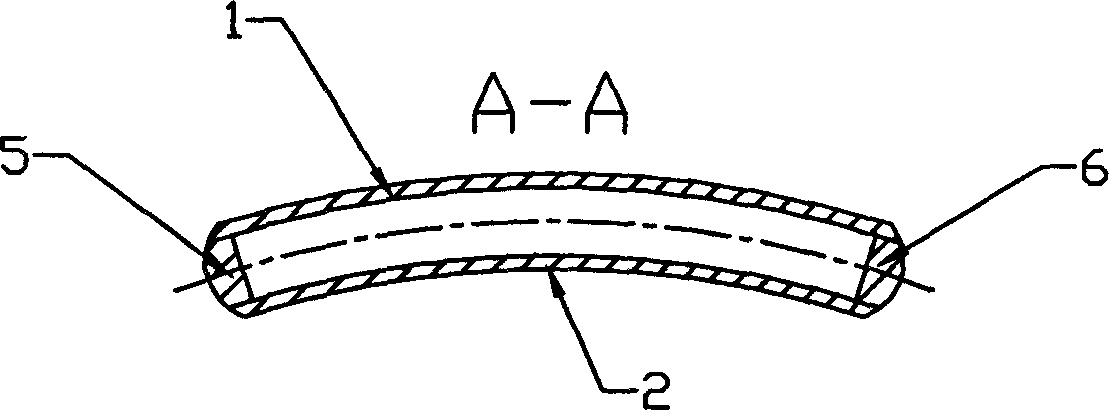

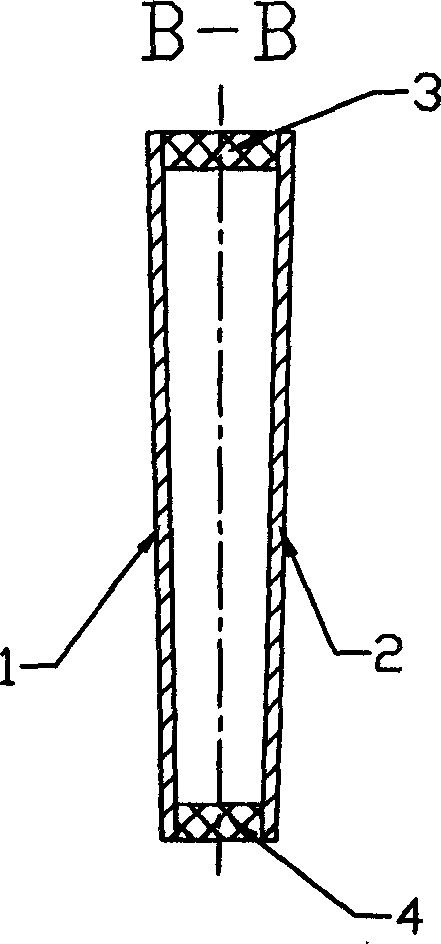

[0014] The arc-shaped profile consists of inner and outer arc wall panels 1 and 2, upper and lower annular plates 3 and 4 and left and right inclined side panels 5 and 6 set on the circumference of the inner and outer arc wall panels. Connection structure, its longitudinal section is inverted tapered (such as image 3 ), the arc-shaped hollow profile is wide at the top and narrow at the bottom (such as figure 1 ).

[0015] The preparation process of the vacuum casting transformer coil isolation airway forming mold of the present invention is carried out according to the following steps, and is composed of a conical inner arc wall plate 1, an inverted conical outer arc wall plate 2, and upper and lower annular plates 3 and 4 Hollow cylindrical body, the distance between the upper and lower annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com