Sand box returning mechanism, returning method using same and vacuum casting line

A technology of vacuum sealing and molding line, which is applied in the field of sand box return mechanism and vacuum sealing molding line, which can solve the problems of high work intensity, safety accidents, and serious insecurity, so as to reduce labor intensity, improve operation efficiency, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

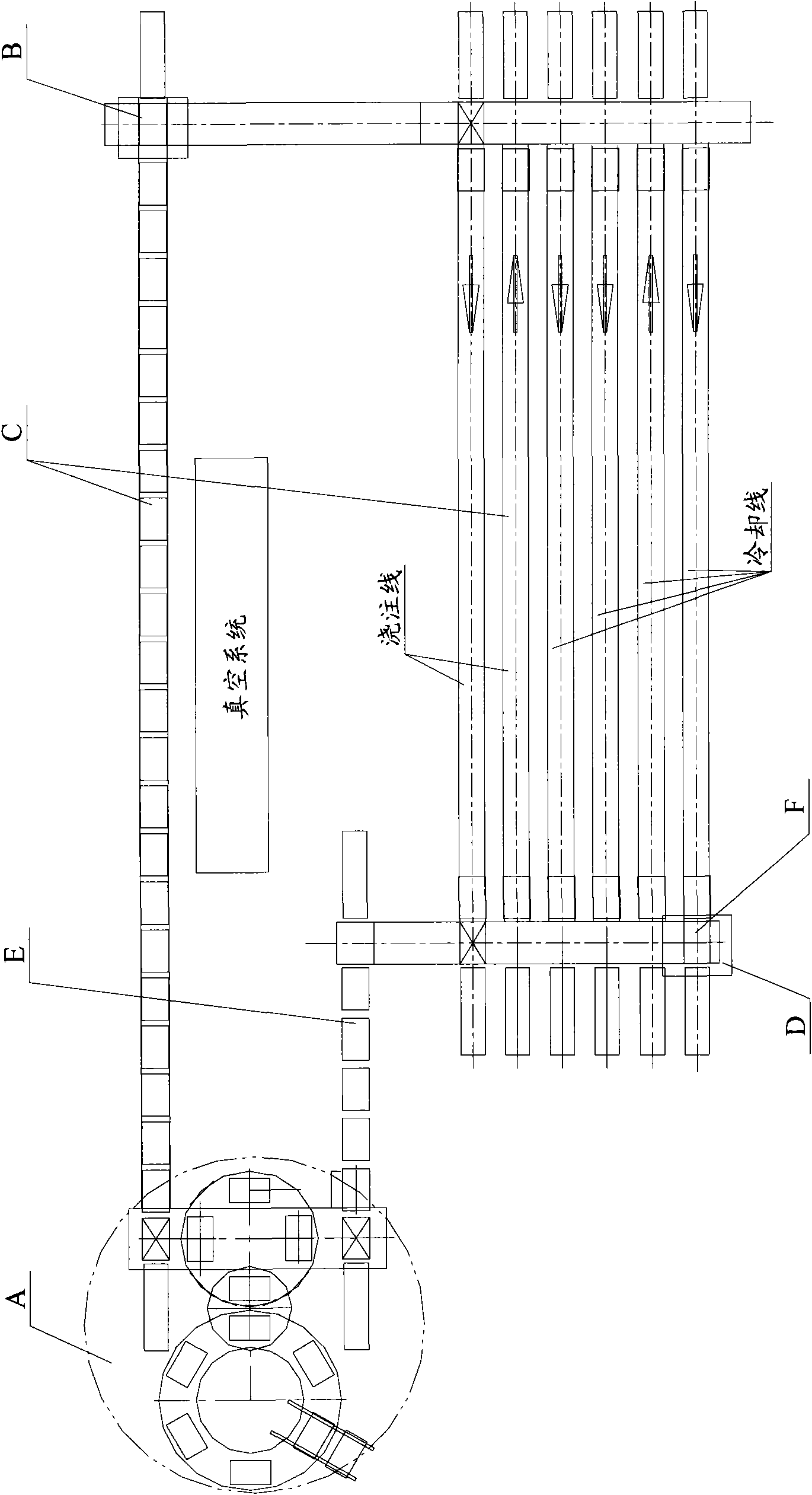

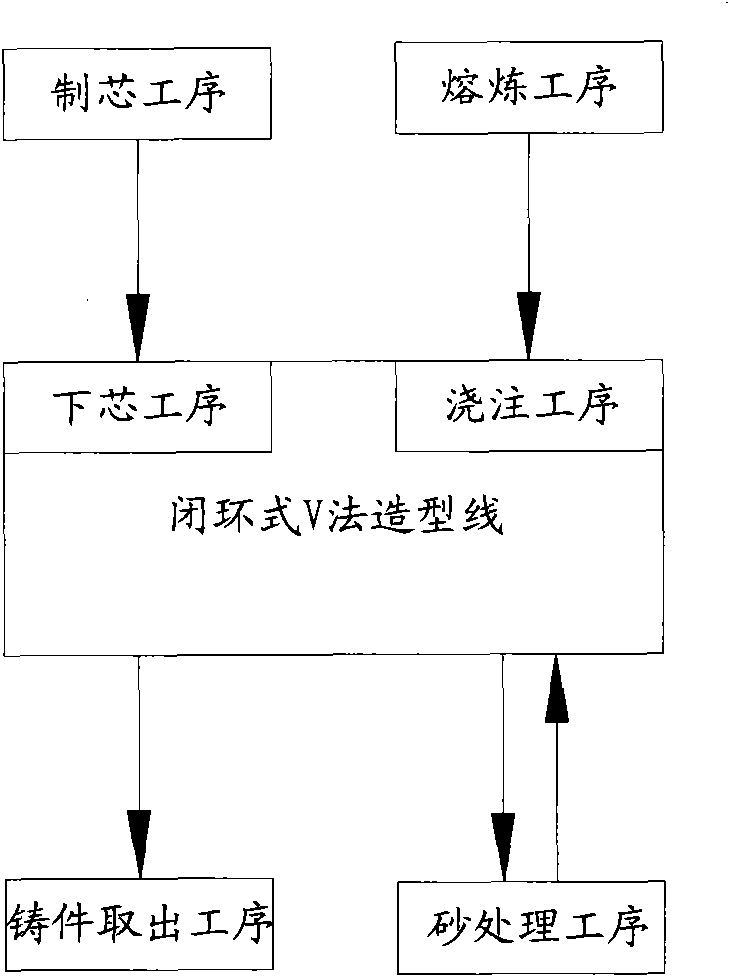

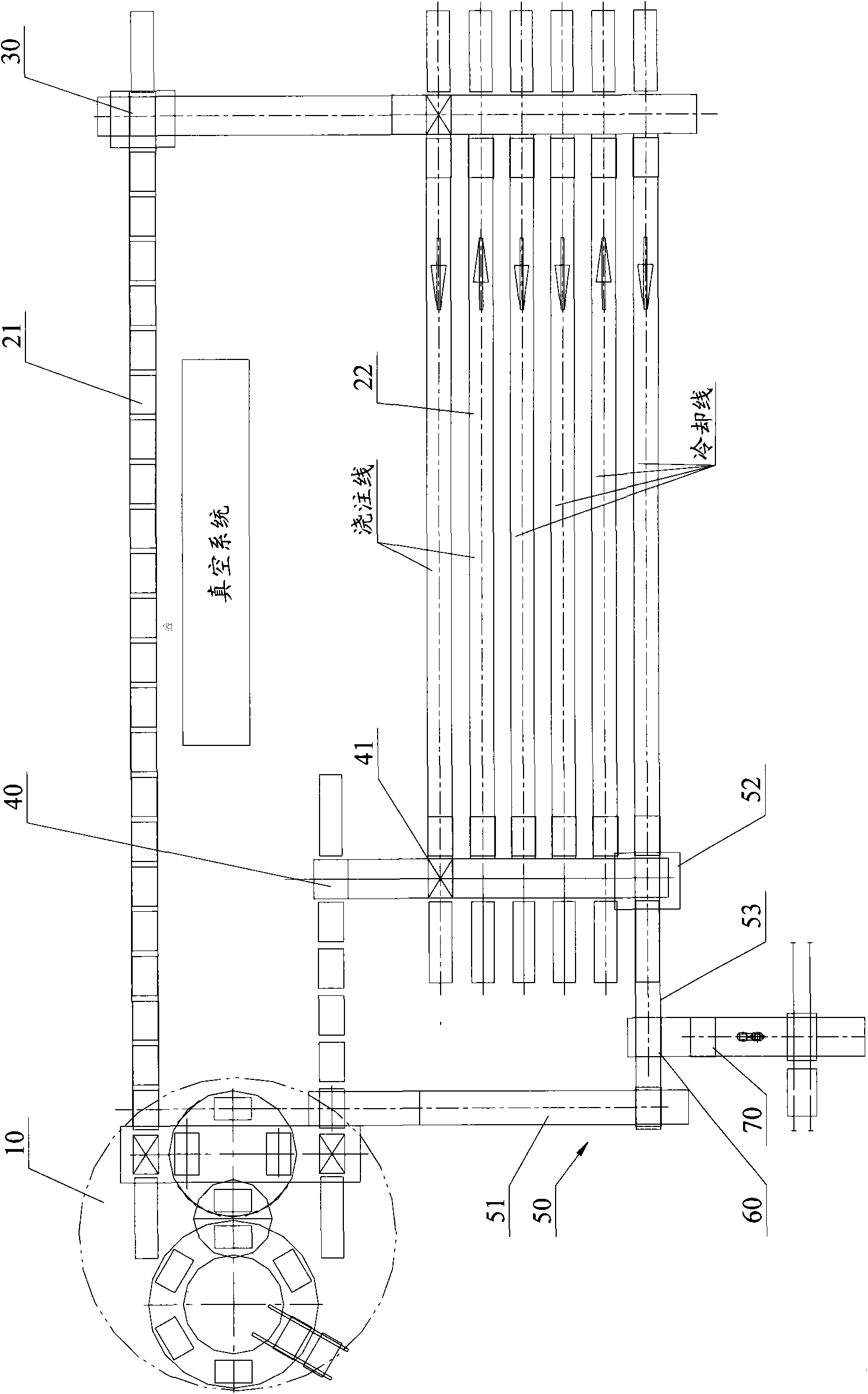

[0041] See figure 2 , which is a schematic diagram of the relationship between the main processes of the casting system.

[0042]The molding process is a process in casting production. In order to realize casting production, in addition to the molding process, there are mainly core making process, core setting process, molten metal melting process, pouring process, casting removal process and sand treatment ( Sand preparation and old sand regeneration) process, etc., the above process constitutes a complete casting process. Among them, the core making process is used to make the core; the core setting process is used to put the core into the prepared mold; the metal smelting process is used to smelt the qualified liquid metal; the pouring process is used to transport the qualified liquid metal to the casting line and pour it into the mold; the cooling process is used to solidify the liquid metal in the mold and lower its temperature to a specified value; the shakeout process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com