Electroslag remelting fluoride-free slag and electroslag remelting method thereof

A technology for electroslag remelting and metal remelting, applied in the fields of electroslag remelting fluorine-free slag and electroslag remelting, it can solve the problem of environmental pollution caused by the stability of the remelting process, affecting the surface finish of steel ingots, uneven thickness of ingots, etc. problems, to achieve the effect of shortening arc starting time and difficulty, suitable cooling and solidification rate, and small degree of ingot segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

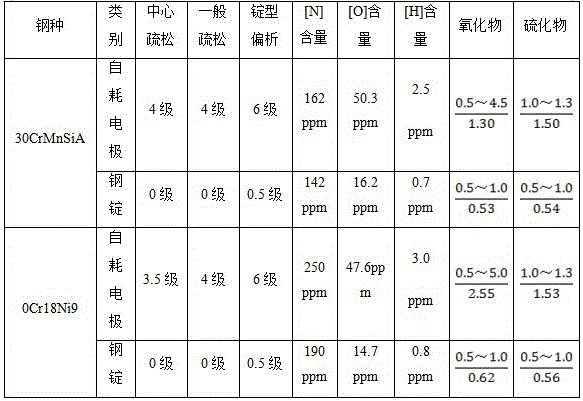

[0024] Embodiment 1 Electroslag remelting produces 30CrMnSiA alloy

[0025] An electroslag remelting fluorine-free slag, comprising the following components by weight: 50 parts of CaO, 40 parts of Al 2 o 3 , 7 parts of MgO and 3 parts of SiO 2 .

[0026] The 30CrMnSiA alloy steel is produced by remelting the above-mentioned electroslag remelting without fluorine slag, and the specific method is as follows:

[0027] 1) Weigh the raw materials according to the above electroslag remelting fluorine-free slag, according to Al 2 o 3 →CaO→SiO 2 →The loading order of MgO is loaded into the slag box, and baked at 800°C for 8 hours to fully remove the moisture in the slag.

[0028] 2) Weld the ∮240mm 30CrMnSiA consumable electrode blank on the dummy electrode;

[0029] 3) Start the arc with a graphite electrode to ignite the fluorine-free slag. The operator observes the melting of the slag in the crystallizer. After the color in the furnace becomes bright, it melts for another 9 ...

Embodiment 2

[0032] Embodiment 2 Electroslag remelting produces 0Cr18Ni9 alloy

[0033] An electroslag remelting fluorine-free slag, comprising the following components by weight: 48 parts of CaO, 42 parts of Al 2 o 3 , 5 parts of MgO and 5 parts of SiO 2 .

[0034] The 0Cr18Ni9 alloy is produced by remelting the above-mentioned electroslag remelting fluorine-free slag, and the specific method is as follows:

[0035] 1) Weigh the raw materials according to the above electroslag remelting fluorine-free slag, according to Al 2 o 3 →CaO→SiO 2 →The order of loading MgO is loaded into the slag box, and baked at 900°C for 10 hours to fully remove the moisture in the slag.

[0036] 2) Weld the ∮240mm 0Cr18Ni9 consumable electrode blank on the dummy electrode;

[0037] 3) Start the arc with a graphite electrode to ignite the fluorine-free slag. The operator observes the melting of the slag in the crystallizer. After the color in the furnace becomes bright, it melts for another 10 minutes. L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com