Continuous casting technology for reducing carbon segregation of wind electricity medium carbon steel continuous casting round billet

A continuous casting round billet and continuous casting process technology, applied in the field of metallurgy, can solve problems such as poor steel quality, harmful steel performance, and large fluctuations in molten steel temperature, so as to reduce the degree of carbon segregation and meet strict requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

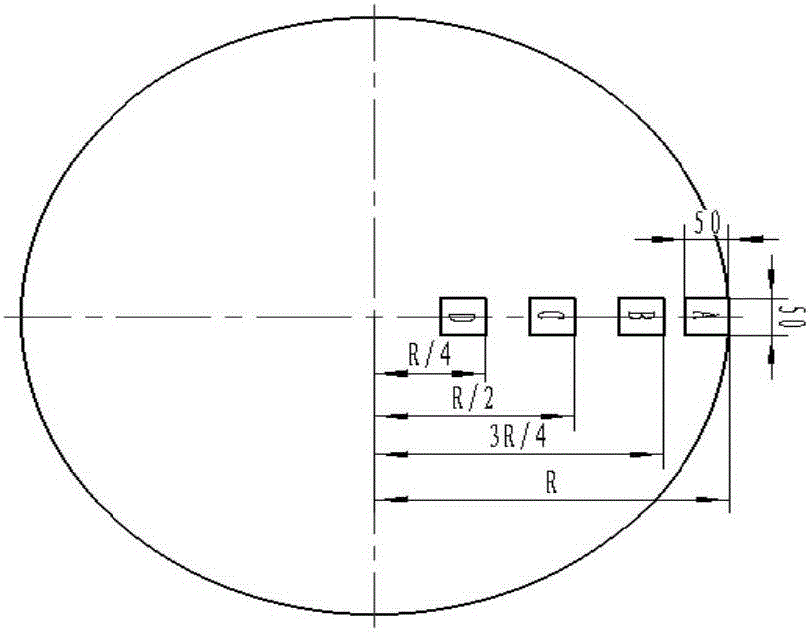

[0019] This embodiment provides a continuous casting process for reducing carbon segregation of carbon steel continuous casting round billets in wind power, which is produced by the process of converter steelmaking, LF refining, RH vacuum degassing, Φ550mm large cross-section round billet continuous casting, and slow cooling Φ550mm large cross-section continuous casting round billet, using this continuous casting process, the degree of carbon segregation deviation of the round billet can be effectively reduced, and the carbon segregation deviation of the continuous casting round billet is controlled within 0.05%. The specific requirements are as follows:

[0020] 1. Converter steelmaking: During the carburization process after BOF smelting and tapping, the argon blowing argon at the bottom of the ladle and the amount of carburization are controlled to ensure strong stirring at 400-600L / min and 8.0-10.0bar argon blowing at the bottom of the ladle. 0.20~0.30% control; after 10 mi...

Embodiment 2

[0029] The difference between this example and Example 1 is that the continuous casting process parameters adopted are as follows: the electromagnetic stirring parameter of the crystallizer is 380 / 3.0Hz, and the stirring method adopts alternating electromagnetic stirring: positive 15s, stop 7s, reverse 15s, stop 7s; The terminal electromagnetic stirring parameter is 200A / 3.0Hz, and the stirring method adopts alternating electromagnetic stirring: positive 25s, stop 5s, reverse 25s, stop 5s; the crystallizer cooling water flow rate is 4700L / min (± 35L), and the secondary cooling spray water volume is 0.18L / min, the water distribution in each zone is 48%, 32%, 20%, and the casting speed is 0.33m / min under the working condition of 25-40°C.

[0030] The slab carbon segregation range produced by the continuous casting process of this embodiment is 0.40-0.47%.

Embodiment 3

[0032] The difference between this example and Example 1 is that the continuous casting process parameters adopted are as follows: the electromagnetic stirring parameter of the crystallizer is 300 / 3.0Hz, and the stirring method adopts continuous electromagnetic stirring; the terminal electromagnetic stirring parameter is 280A / 3.0Hz, and the stirring method Alternate electromagnetic stirring is adopted: forward 25s, stop 5s, reverse 25s, stop 5s, crystallizer cooling water flow rate is 4700L / min (±35L), secondary cooling spray water volume is 0.18L / min, water distribution in each area is 48%, 32%, 20%, the casting speed is 0.33m / min under the working condition of 25~40℃.

[0033] The slab carbon segregation range produced by the continuous casting process of this embodiment is 0.38-0.50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com