Manufacturing method of steel and forge piece thereof for valve seat of deep sea oil extraction equipment

A manufacturing method and technology for steel forgings, which are applied in the field of manufacturing steel for valve seats of deep-sea oil production equipment and forgings, can solve the problems of reduced effective bearing capacity, complex structure, large internal stress, etc., and achieve corrosion resistance and comprehensive mechanical properties. The effect of improving and improving comprehensive mechanical properties and low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

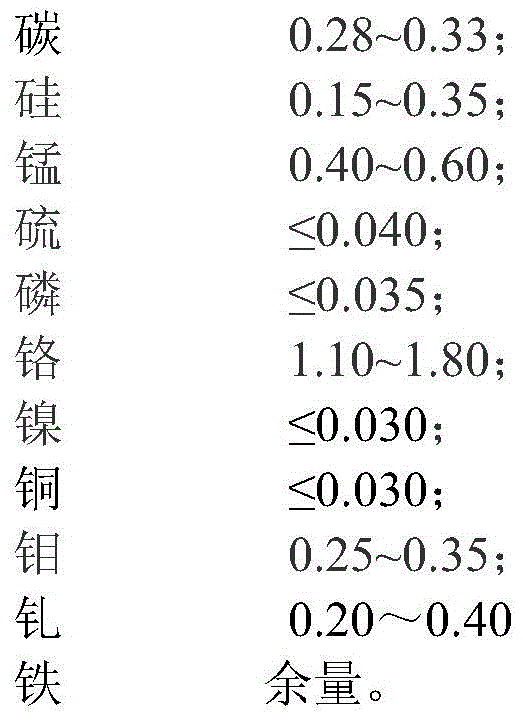

[0032] (1) According to the size of the valve seat of deep sea oil production equipment, select the appropriate steel blank. Described iron and steel material comprises each component of following mass percent (wt.%):

[0033]

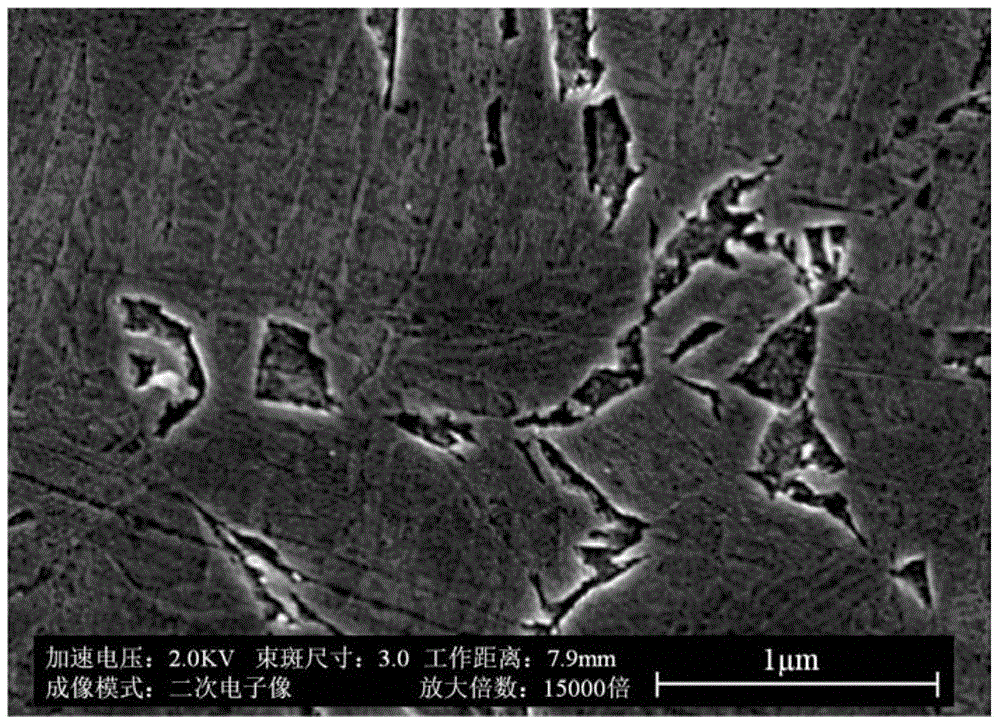

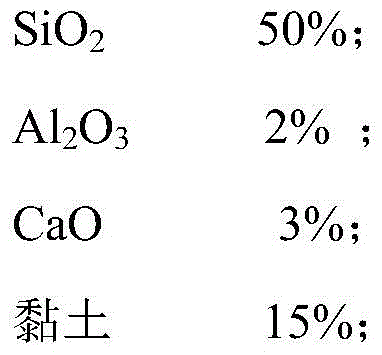

[0034] According to the size of the required structural parts, choose a 5.4-ton octagonal plum blossom ingot, and coat a layer of glass-like coating on the surface of the billet. The main component of the glass-like coating is (wt.%): 50% SiO 2 +2%Al 2 o 3+3% CaO+15% clay+30% water glass. Then put it into the furnace and heat it to 1300°C for 3 hours to keep it out of the furnace, press the pliers handle on a 35MN free forging and quick forging hydraulic press, and chamfer. Upsetting in the axial direction to a height-to-diameter ratio of 0.84 (the height after upsetting is 800 mm). Chop and cut the pliers, use 600mm wide upper and lower flat anvils to elongate along the radial direction of the steel ingot, the deformation amount is 20-25%, repe...

Embodiment 2

[0040] (1) According to the size of the valve seat of deep sea oil production equipment, select the appropriate steel blank. Described iron and steel material comprises each component of following mass percent (wt.%):

[0041]

[0042] According to the size of the required structural parts, choose a 5.4-ton octagonal plum blossom ingot, and coat a layer of glass-like coating on the surface of the billet. The main component of the glass-like coating is (wt.%): 50% SiO 2 +2%Al 2 o 3 +3% CaO+15% clay+30% water glass. Then put it into the furnace and heat it to 1300°C for 3 hours to keep it out of the furnace, press the pliers handle on a 35MN free forging and quick forging hydraulic press, and chamfer. Upsetting in the axial direction to a height-to-diameter ratio of 0.84 (the height after upsetting is 800 mm). Chop and cut the pliers, use 600mm wide upper and lower flat anvils to elongate along the radial direction of the steel ingot, the deformation amount is 20-25%, rep...

Embodiment 3

[0048] (1) According to the size of the valve seat of deep sea oil production equipment, select the appropriate steel blank. Described iron and steel material comprises each component of following mass percent (wt.%):

[0049]

[0050]

[0051] According to the size of the required structural parts, choose a 5.4-ton octagonal plum blossom ingot, and coat a layer of glass-like coating on the surface of the billet. The main component of the glass-like coating is (wt.%): 50% SiO 2 +2%Al 2 o 3 +3% CaO+15% clay+30% water glass. Then put it into the furnace and heat it to 1300°C for 3 hours to keep it out of the furnace, press the pliers handle on a 35MN free forging and quick forging hydraulic press, and chamfer. Upsetting in the axial direction to a height-to-diameter ratio of 0.84 (the height after upsetting is 800 mm). Chop and cut the pliers, use 600mm wide upper and lower flat anvils to elongate along the radial direction of the steel ingot, the deformation amount is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com