Preparation and synthesis method of hexagonal flaky magnesium hydroxide fire retardant

A technology of magnesium hydroxide and a synthesis method, applied in directions such as magnesium hydroxide, can solve the problems of uncontrollable particle size of flaky magnesium hydroxide, low surface polarity and surface energy, poor morphology stability, etc. Good stability, improved mechanical properties, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

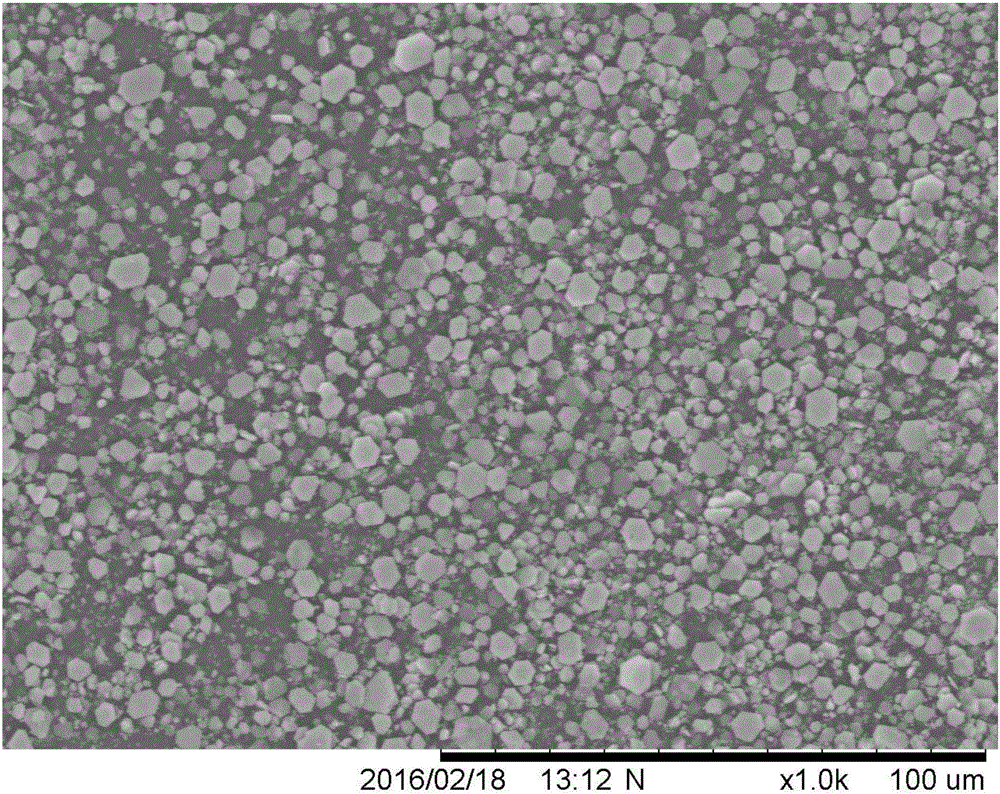

[0036]Add magnesium salt solution (concentration range is 1mol / L), crystal directing agents A1 and B1 (concentration range is 7.2×10-3g / L) into the reaction vessel, stir evenly at 35°C, and place Inorganic alkali solution (concentration range is 4mol / L) is added dropwise into the reaction vessel at a constant rate (rate range is 15L / min). After the reaction is complete, the reaction slurry is ultrasonically oscillated for 20 minutes and then transferred to a volume of 1m3 under high pressure. In the reaction kettle, add absolute ethanol (80%-95% ethanol by mass fraction, the addition accounts for 6% of the total volume), carry out the hydrothermal reaction temperature is 180 ℃, and the reaction time is 40h, finally through pressure filtration, water washing, Alcohol washing, drying made magnesium hydroxide product, the product's SEM, DTG-TG and XRD test results are as attached figure 1 , attached Figure 4 And attached Figure 5 shown.

Embodiment 2

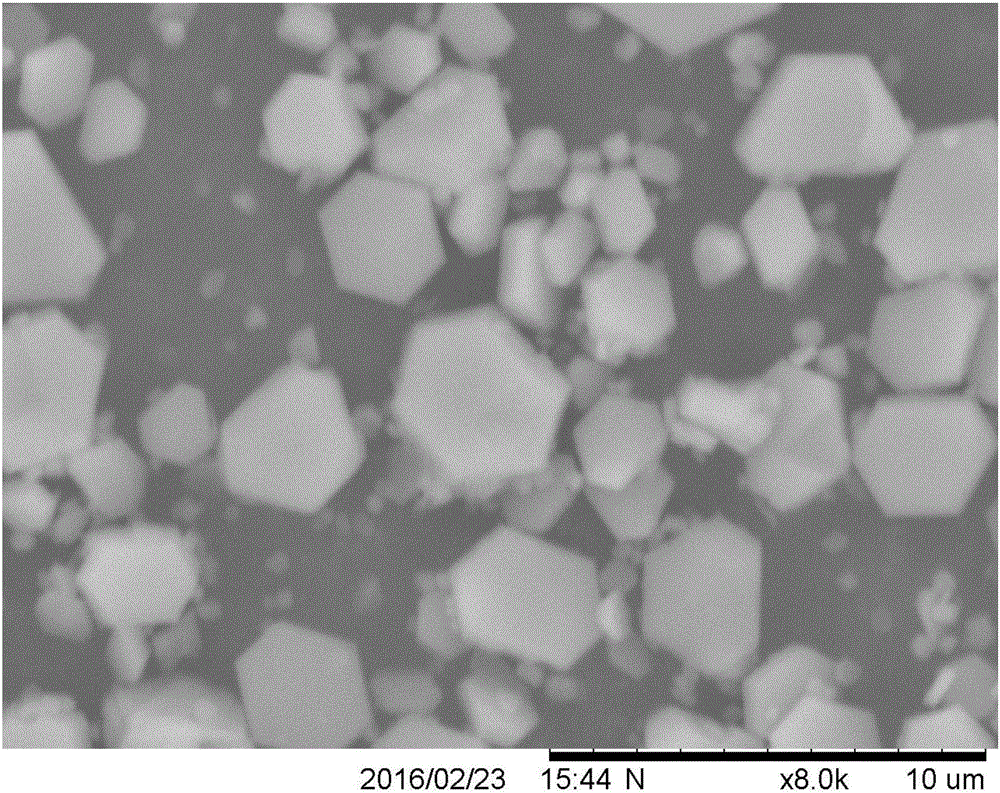

[0038] Add magnesium salt solution (concentration range is 3mol / L), crystal directing agents A2 and B2 (concentration range is 3.5×10-2g / L) in reaction vessel, stir evenly under the condition of 46 ℃, under this temperature condition Inorganic alkaline solution (concentration range: 5.5mol / L) was added dropwise into the reaction vessel at a constant rate (rate range: 25L / min). After the reaction was complete, the reaction slurry was ultrasonically oscillated for 26 minutes and then transferred to a volume of 1m3 In the autoclave, add absolute ethanol (ethanol with a mass fraction of 80%-95%, the amount added accounts for 11% of the total volume), carry out the hydrothermal reaction temperature at 200°C, and the reaction time is 48h, and finally pass through pressure filtration and water washing , alcohol washing, and drying to obtain magnesium hydroxide products, the SEM test results of the products are attached figure 2 shown.

Embodiment 3

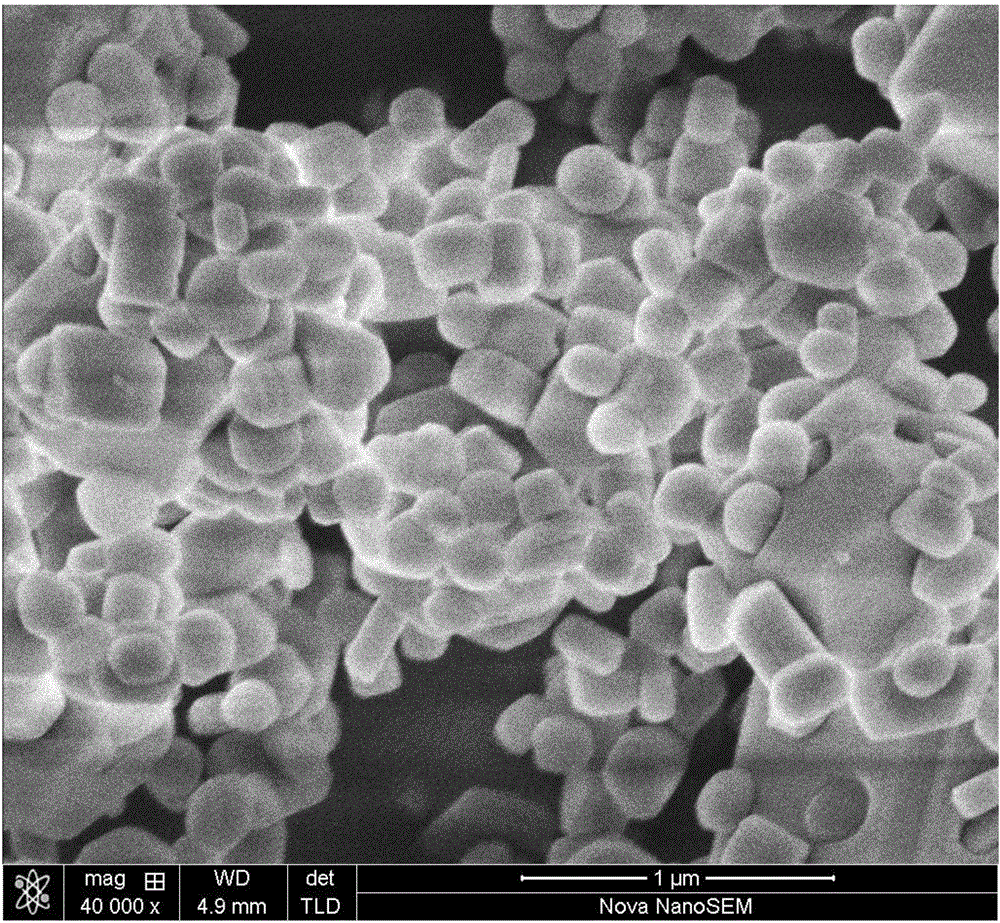

[0040] Add magnesium salt solution (concentration range is 2.6mol / L) in reaction vessel, stir evenly under 48 ℃ of conditions, under this temperature condition, inorganic alkali solution (concentration range is 5.8mol / L) with constant rate (rate The range is 31L / min) into the reaction vessel dropwise, after the reaction is complete, the reaction slurry is ultrasonically oscillated for 28min and then transferred to a volume of 1m3 high-pressure reactor, adding absolute ethanol (mass fraction 80%-95%) Ethanol, the addition accounts for 17% of the total volume), the hydrothermal reaction temperature is 190°C, the reaction time is 38h, and finally the magnesium hydroxide product is obtained through pressure filtration, water washing, alcohol washing and drying, and the SEM test of the product The results are attached image 3 .

[0041] attached by figure 1 It can be seen that the magnesium hydroxide flame retardant material produced by the system of adding crystallization direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com