Brazing mixture and method for preparing diamond brazing string beads from brazing mixture

A mixture of materials and diamond technology, applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve the problems of low production efficiency, difficulty in mass production, difficulty in mass production, and high production costs, and achieve affinity Good, the effect of improving wear resistance and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of brazing mixture of the present embodiment includes: brazing powder, modifier and forming agent, and the modifier is high hardness powder composed of tungsten carbide and molybdenum carbide in a mass ratio of 1:1, which The dosage is 10% (W / W) of the mass of the brazing powder; the forming agent is 4.0% of the mass of the brazing powder and a paraffin gasoline solution with a concentration of 15%.

[0040] The brazing powder is BNi 2 Nickel alloy brazing powder.

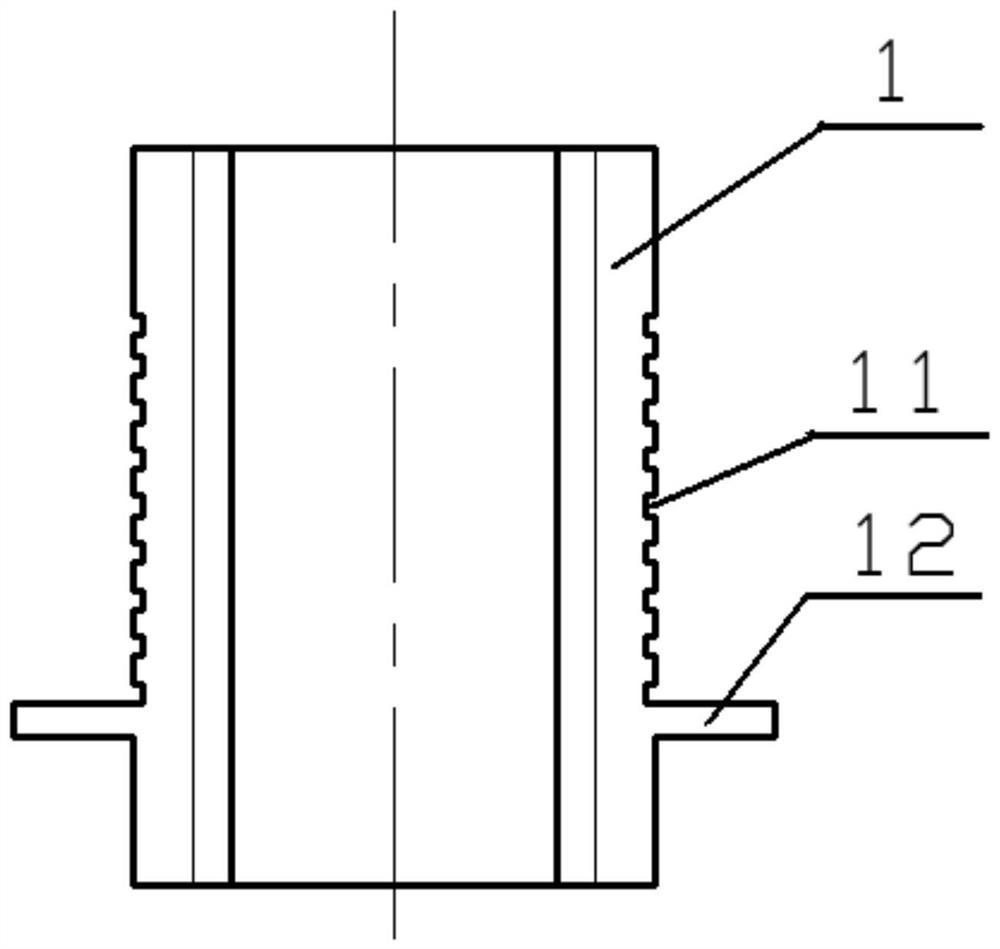

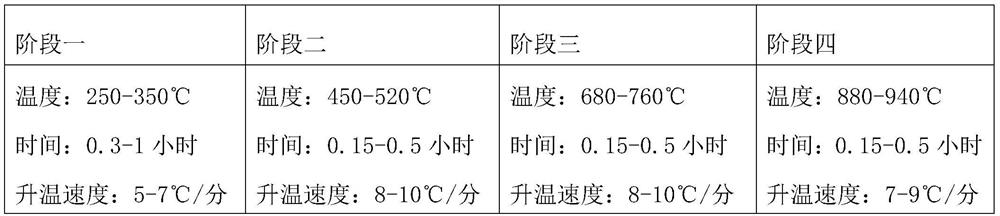

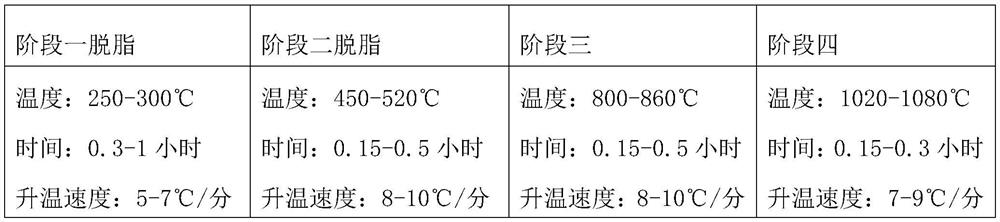

[0041] refer to figure 1 , a method for preparing diamond brazing beads of the present implementation The method for preparing diamond brazing beads comprises the following steps:

[0042] One, the preparation of brazing mixture, comprises the following steps:

[0043] 1) 200 mesh BNi 2 Nickel alloy brazing powder was ball-milled for 10 minutes in a planetary ball mill under the protection of argon, the ball-to-material ratio was 6:1, the milling speed was 400r / min, the balls were made of silicon ...

Embodiment 2

[0051] A brazing mixture in this embodiment includes: brazing powder, a modifier and a forming agent, the modifier is a high-hardness powder composed of titanium diboride and molybdenum carbide in a mass ratio of 2:1 , its dosage is 15% (W / W) of the mass of the solder powder; the forming agent is 3.5% of the mass of the solder powder and a 20% concentration of acrylic acid-methyl methacrylate solution.

[0052] The brazing powder is CuSnTi10 copper alloy brazing powder.

[0053] refer to figure 1 , a method for preparing diamond brazing beads of the present implementation The method for preparing diamond brazing beads comprises the following steps:

[0054] One, the preparation of brazing mixture, comprises the following steps:

[0055] 1) Ball mill 200-mesh CuSnTi10 copper alloy brazing powder in a planetary ball mill for 20 minutes under argon protection, the ball-to-material ratio is 5:1, the milling speed is 450r / min, the balls are made of silicon nitride, and pass 325 m...

Embodiment 3

[0064] A kind of brazing mixture of the present embodiment comprises: fine-grained alloy powder, modifier and forming agent, and described modifier is 15:1 by mass ratio by titanium diboride, chromium carbide and dimolybdenum carbide: 1 composition of high-hardness powder, the amount of which is 17% (W / W) of the mass of the fine-grained alloy powder; the forming agent is 3.8% of the mass of the fine-grained alloy powder and a PVA aqueous solution with a concentration of 20%.

[0065] The fine particle alloy powder is an alloy powder mixed with 300-mesh electrolytic copper powder, 200-mesh tin powder, and 200-mesh titanium dihydride powder at a mass ratio of 72:18:10.

[0066] refer to figure 1 , a method for preparing diamond brazing beads of the present implementation The method for preparing diamond brazing beads comprises the following steps:

[0067] One, the preparation of brazing mixture, comprises the following steps:

[0068] 1) Mix 300-mesh electrolytic copper powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com