Sand making device for building engineering

A technology for construction engineering and mounting racks, used in grain processing and other directions, can solve problems such as uneven grinding size of sand grains, and achieve the effects of improving grinding uniformity, long service life, and changing particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

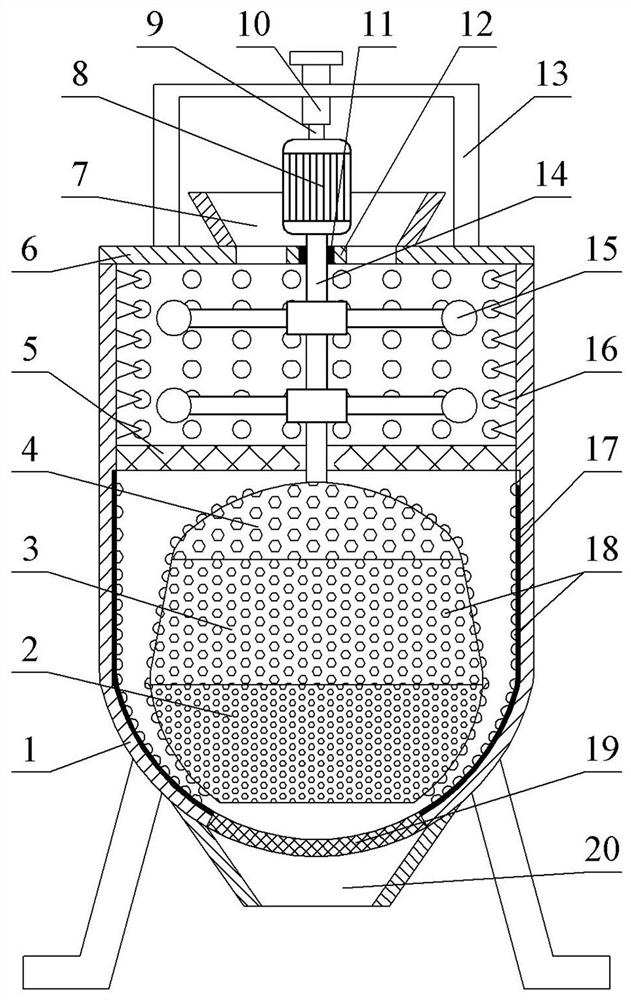

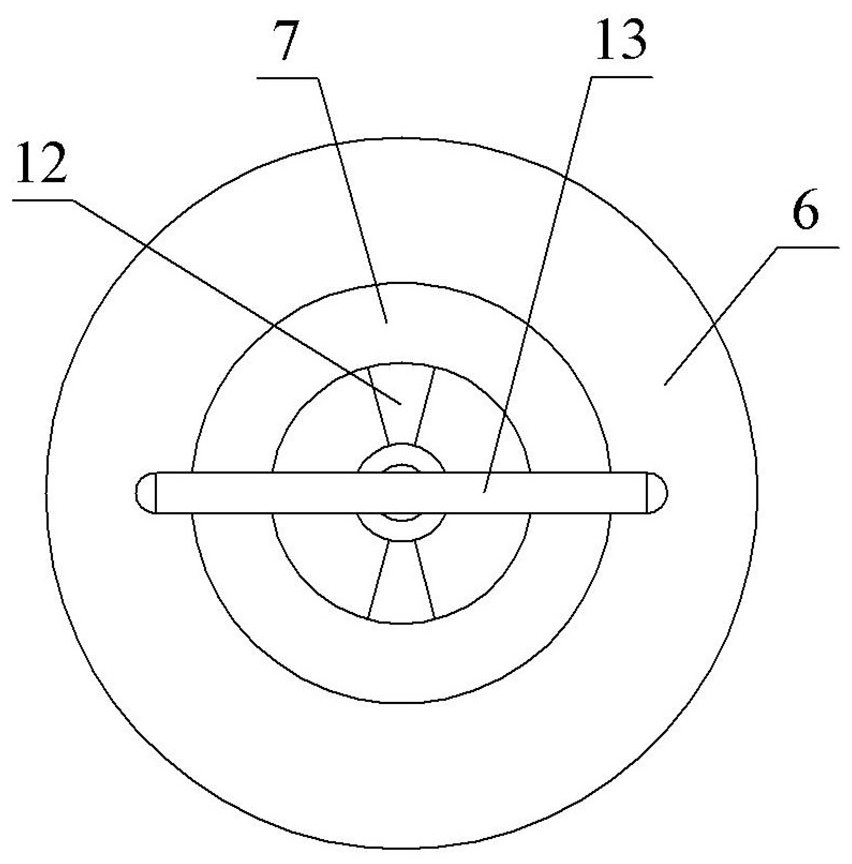

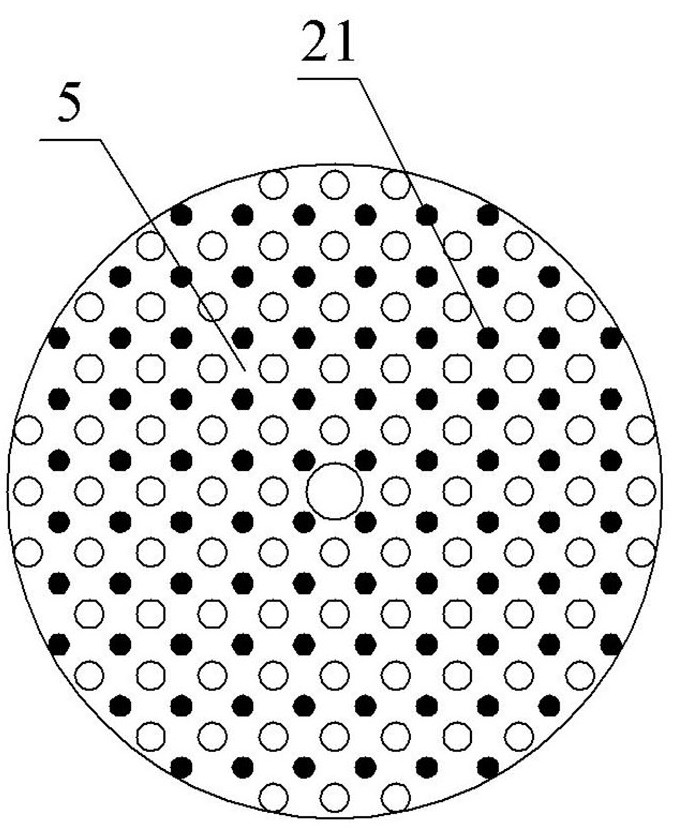

[0019] Such as Figure 1-3 As shown, a sand making device for construction engineering, it includes a cylinder 1, the top opening of the cylinder 1 is provided with an end cover 6, and the center of the end cover 6 is provided with a feed port 7, A mounting frame 12 is provided in the feed inlet 7, and a vertical shaft 14 is connected to rotate on the mounting frame 12, and a crushing hammer 15 is connected to the vertical shaft 14 in the cylinder body 1. A filter plate 5 is arranged below the crushing hammer 15 on the inner side of the cylinder 1, and a grinding block is connected below the filter plate 5 on the vertical axis 14, and the inner side of the cylinder 1 corresponds to the grinding block. A grinding seat 17 is provided at the position of the grinding block, and the surface of the grinding block and the grinding seat 17 is provided with a grinding protrusion 18, and a screen 19 is arranged below the grinding block on the bottom end surface of the cylinder body 1, a...

Embodiment 2

[0022] Such as Figure 1-3 As shown, a sand making device for construction engineering, it includes a cylinder 1, the top opening of the cylinder 1 is provided with an end cover 6, and the center of the end cover 6 is provided with a feed port 7, A mounting frame 12 is provided in the feed inlet 7, and a vertical shaft 14 is connected to rotate on the mounting frame 12, and a crushing hammer 15 is connected to the vertical shaft 14 in the cylinder body 1. A filter plate 5 is arranged below the crushing hammer 15 on the inner side of the cylinder 1, and a grinding block is connected below the filter plate 5 on the vertical axis 14, and the inner side of the cylinder 1 corresponds to the grinding block. A grinding seat 17 is provided at the position of the grinding block, and the surface of the grinding block and the grinding seat 17 is provided with a grinding protrusion 18, and a screen 19 is arranged below the grinding block on the bottom end surface of the cylinder body 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com