Crushing device used in pretreatment stage of sodium sulphide raw materials

A technology of raw material pretreatment and pulverization device, applied in grain treatment, alkali metal sulfide/polysulfide, etc., can solve the problems of mirabilite, coal powder reaction incomplete, coal powder calcination incomplete, low sodium sulfide yield, etc. Achieve the effect of shortening the production cycle, increasing the scope of application, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

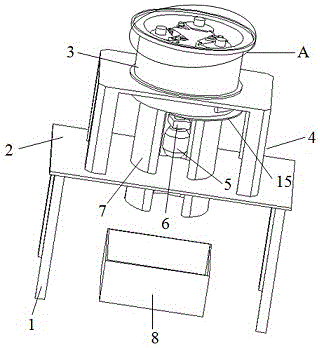

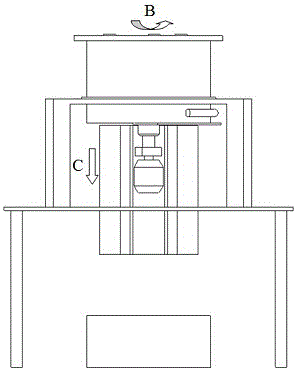

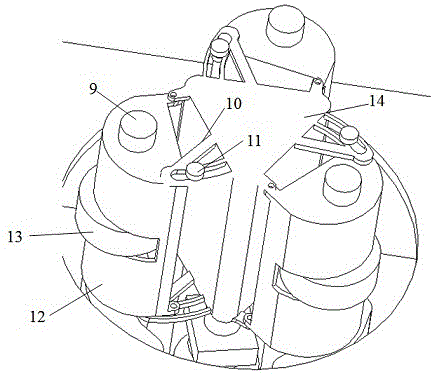

[0021] Compare below Figure 1 to Figure 3 To illustrate, due to the harsh working environment during the crushing operation, it is important to check the connection between the triangular block 14 and the squeeze roller 12 in the squeeze crushing mechanism in the crushing barrel 3 before the device works, and at the same time ensure that each The components are reliably connected to avoid safety accidents, and then adjust the position of the squeeze roller 12 in the chute frame 10 according to the particle size of the required pulverized material, and conduct a trial run to observe whether the mechanism is running smoothly, and the device is completed. Preparation.

[0022] Before the device works, the staff puts the finished material box 8 directly below the discharge pipe 7, then the crushing motor 3 is started, and the triangular block 14 is driven to rotate through the reducer 6, and the triangular block 14 drives the extrusion crushing mechanism to operate, and At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com