Hot in-place asphalt recycling apparatus and road paving method using same

A technology of asphalt regeneration and asphalt pavement, which is applied in the direction of roads, roads, road repairs, etc., can solve problems such as delayed work, height differences of surrounding structures, accident risks, etc., and achieve the effect of preventing strength decline, preventing changes, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention are described below with reference to the accompanying drawings.

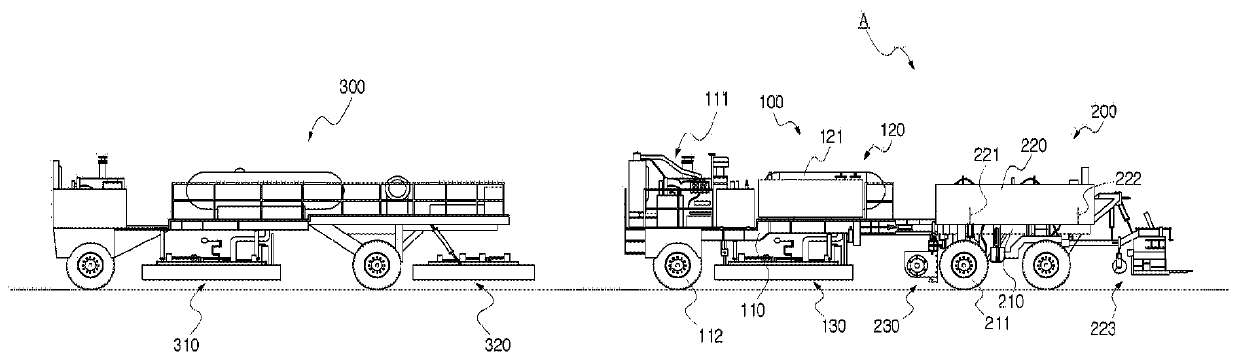

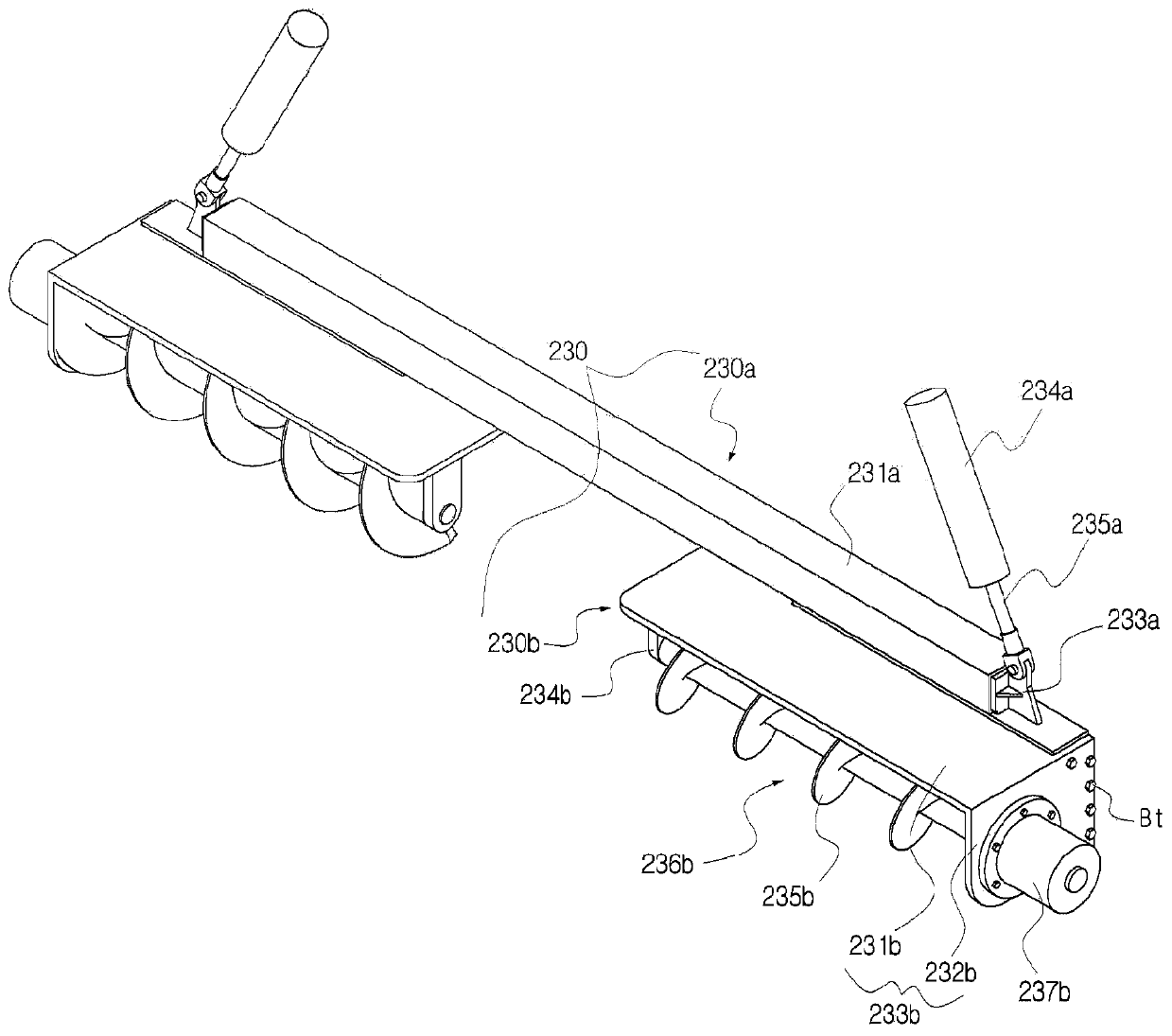

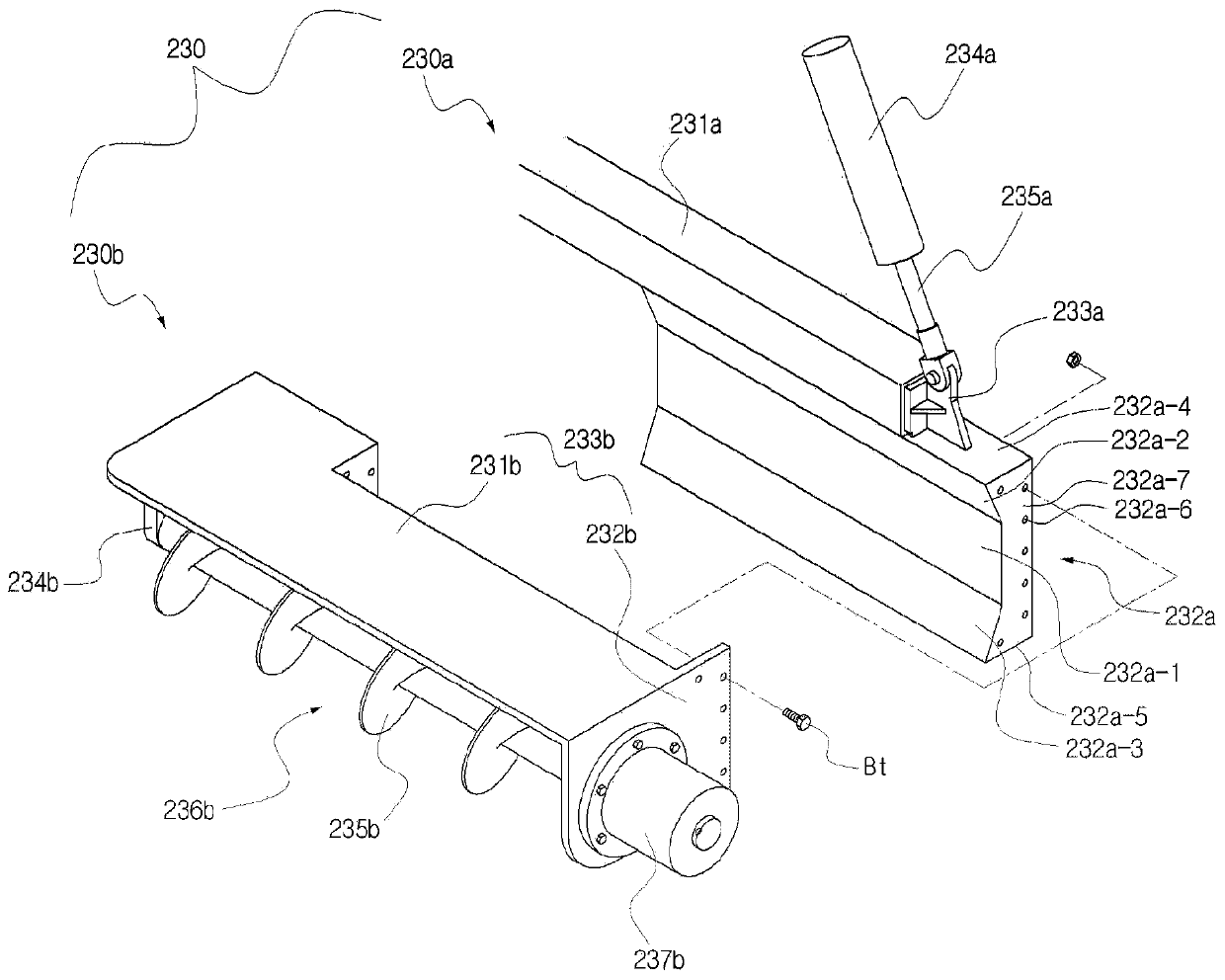

[0047] figure 1 is a front view showing the on-site heating asphalt regeneration device of the present invention, figure 2 It is a perspective view showing the road surface removal part in the on-site heating asphalt regeneration device of the present invention, image 3 It is a perspective view in which the road surface scraping part and the road surface transfer gathering part of the road surface removal part in the on-site heating asphalt regeneration device of the present invention are separated and illustrated, Figure 4 It is a bottom perspective view in which the road surface scraping part and the road surface transfer gathering part of the road surface removal part in the on-site heating asphalt regeneration device of the present invention are separated and illustrated, Figure 5 It is a side view showing the road surface removal part in the heating-in-plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com