Compound pendulum double-cavity jaw crusher

A jaw crusher and machine body technology, applied in grain processing, etc., can solve problems such as low crushing efficiency, high power consumption, and difficult crushing, and achieve high crushing efficiency, low power consumption, and good crushing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

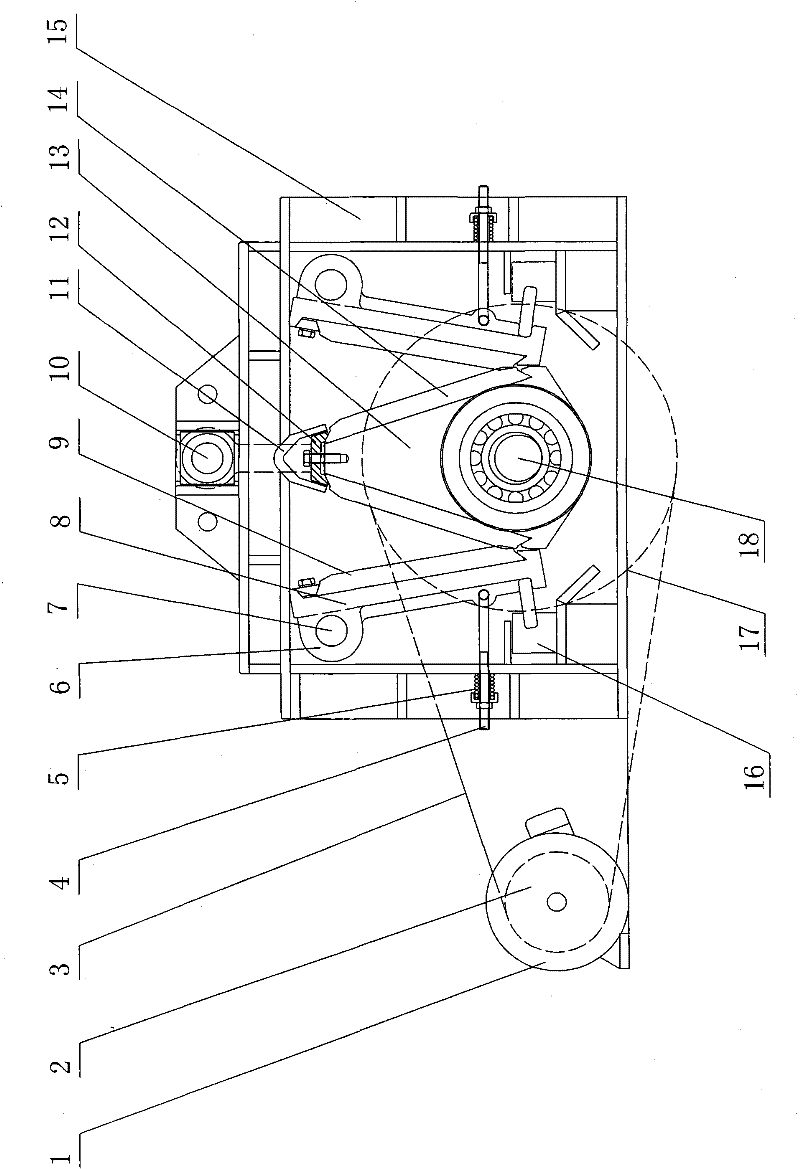

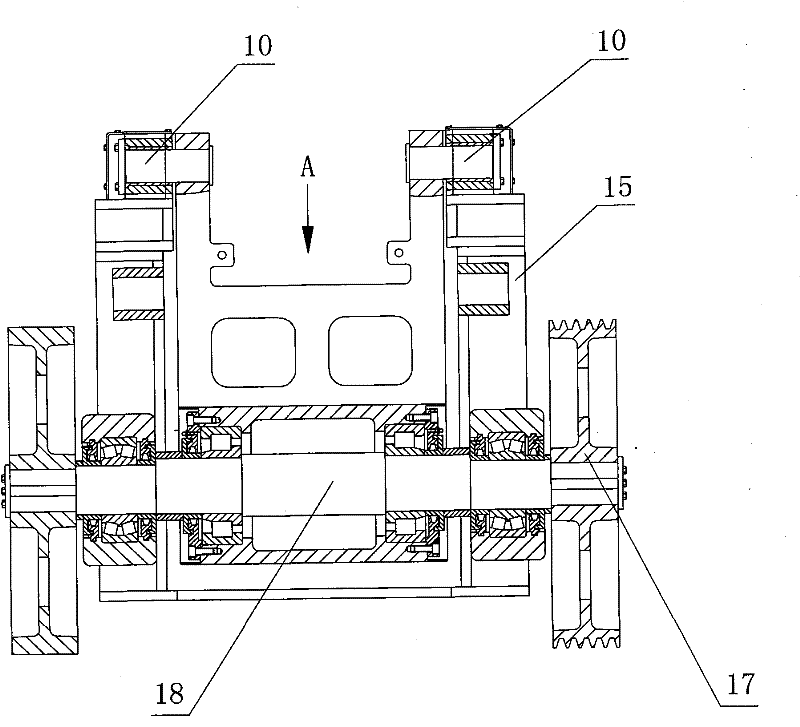

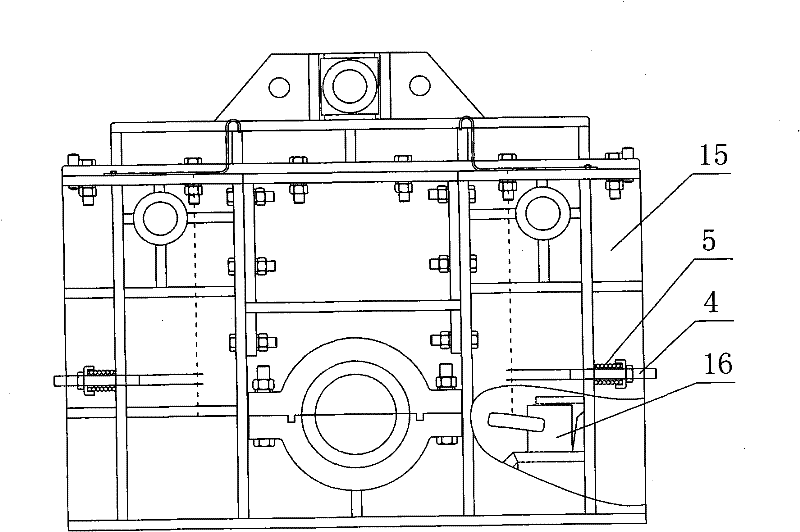

[0013] Such as Figure 1 ~ Figure 3 As shown, the compound pendulum double-cavity jaw crusher: the upper end of the body (15) is provided with a slider group (10), and the slider group (10) is connected with the double-sided movable jaw body (13) placed in the body (15) , the two movable jaw plates (14) are respectively fixed on both sides of the double-sided movable jaw body (13) through the movable jaw platen (12), and the upper end of the movable jaw platen (12) is provided with a distribution plate (11); The lower end of the face movable jaw body (13) is connected with the eccentric shaft (18), the eccentric shaft (18) is connected with the pulley II (17), the pulley II (17) is connected with the pulley I (2) through the V-belt (3), and the pulley I (2) Connected with the motor (1), the motor (1) drives the eccentric shaft (18) to rotate; the two sides of the body (15) are respectively provided with fixed jaw frames (6), and one end of the fixed jaw frame (6) passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com