Reproduced energy-saving material produced by using waste raw material and usage thereof

An energy-saving and raw material technology, applied in the field of renewable and energy-saving materials, can solve problems such as destruction of the natural environment, casualties, traffic accidents, destruction, etc., and achieve the effects of reducing environmental pollution, wide sources of materials, and saving metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The raw material composition and weight percentage of the renewable energy-saving material are:

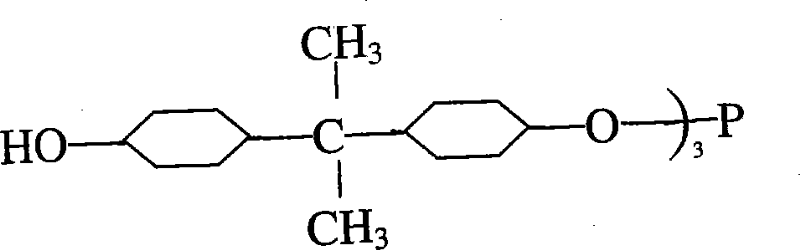

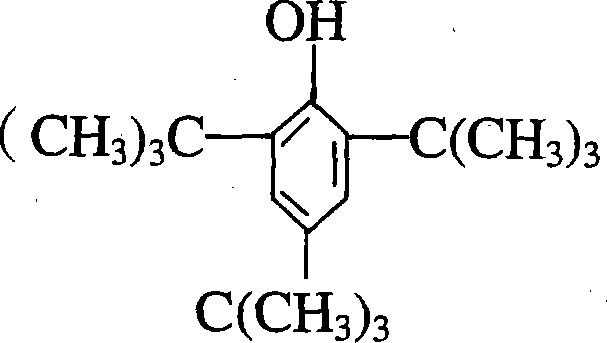

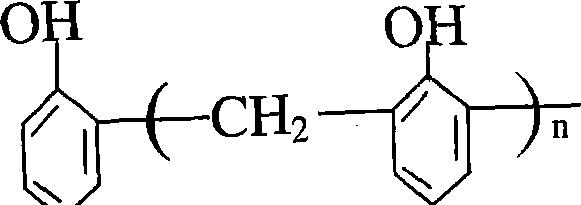

[0020] Waste polyvinyl chloride, waste polyethylene and waste polypropylene mixed recycled particles 52%, waste tailings sand 42%, silane crosslinking agent 0.5%, antioxidant bisphenol A phosphite or 2,4,6-tri-tert-butyl 0.2% of phenol, 2% of epoxy-modified phenolic resin or petroleum resin, 0.5% of chromium cadmium zinc heat stabilizer, 1% of waste engine oil, the rest is industrial ethanol, and the sum of the contents of each component is equal to 100%.

[0021] Its preparation process is: in order to ensure that the reinforcing filler and additives are fully mixed, the materials are mixed with recycled particles of waste tailings sand, waste polyvinyl chloride, waste polyethylene and waste polypropylene, and epoxy-modified phenolic formaldehyde according to the above formula. Resin or petroleum resin, silane crosslinking agent, antioxidant bisphenol A phosphite or 2,4,6-...

Embodiment 2

[0023] The raw material composition and weight percentage of the renewable energy-saving material are:

[0024] Waste polyvinyl chloride, waste polyethylene and waste polypropylene mixed recycled particles 42%, waste tailings sand 52%, silane crosslinking agent 0.8%, antioxidant bisphenol A phosphite or 2,4,6-tri-tert-butyl 0.5% of phenol, 2% of epoxy-modified phenolic resin or petroleum resin, 0.5% of chromium cadmium zinc heat stabilizer, 1.5% of waste engine oil, and the rest is industrial ethanol. The sum of the contents of each component is equal to 100%.

[0025] Its preparation process is with embodiment 1.

Embodiment 3

[0027] The raw material composition and weight percentage of the renewable energy-saving material are:

[0028] Waste polyvinyl chloride, waste polyethylene and waste polypropylene mixed recycled particles 47%, waste tailings sand 47%, silane crosslinking agent 0.6%, antioxidant bisphenol A phosphite or 2,4,6-tri-tert-butyl 0.4% of phenol, 2% of epoxy-modified phenolic resin or petroleum resin, 1% of zinc cadmium heat stabilizer, 1% of waste engine oil, and the rest is industrial ethanol. The sum of the contents of each component is equal to 100%.

[0029] Its preparation process is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com