Lubricating oil and preparation method thereof

A technology of lubricating oil and petroleum ether, which is applied in the field of lubricating oil, can solve problems such as failure to meet customer requirements, unstable friction coefficient, poor solubility, etc., and achieve good results, reduced volatilization, and low solvent prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

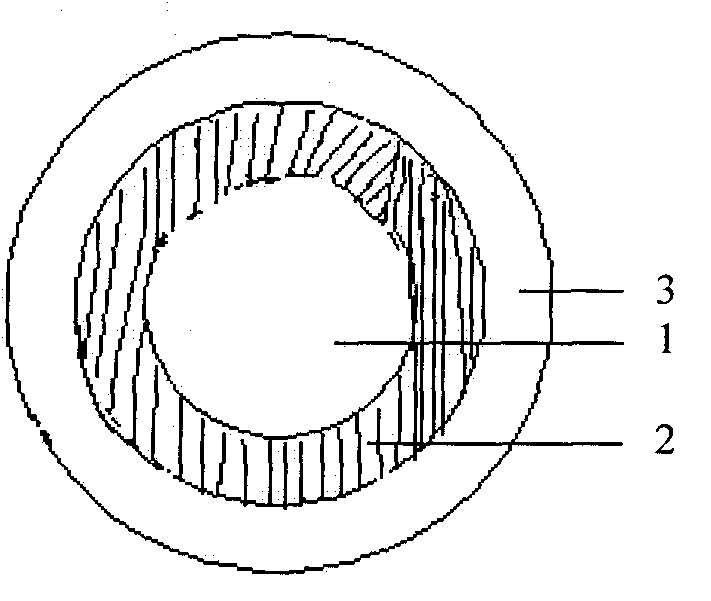

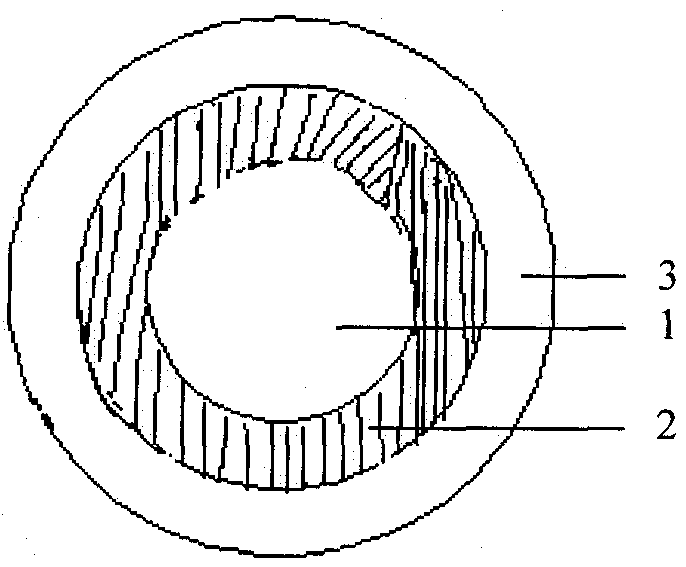

Image

Examples

preparation example Construction

[0013] A method for preparing lubricating oil, characterized in that: the method for preparing lubricating oil includes the following steps: a. Weigh 0.1-1% by weight of fatty acid ester into the heating reactor attached, and heat the reactor To 60~70℃, make the fatty acid ester fully melt; b. Weigh 99-99.9% of the fatty solvent by weight, and add 3 to 5 times the weight of fatty acid ester to the fatty acid in step a In the ester solution and stir until it is uniform and non-colloid. Under this condition, use the pump to add the remaining weight of aliphatic solvent and stir it until the dissolution is complete; c. Transfer the configured lubricating oil into a clean oil drum with a seal , Sealed and stored. In step a, the reaction kettle is heated in an oil bath or a water bath, and the fatty acid ester can be one or a mixture of the following substances: carnauba wax, beeswax, paraffin wax and montan wax. Fatty acid esters can also be made by mixing 50% by weight beeswax an...

Embodiment 1

[0031] Lubricating oil raw materials and preparation methods are as follows:

[0032] Raw materials: fatty acid esters (paraffin wax and beeswax each account for 50%), aliphatic solvents (petroleum ether and 120# solvent each account for 50%). Paraffin wax (produced by Shanghai Huashen Rehabilitation Equipment Co., Ltd.): colorless and transparent solid, melting point: 58~62℃, insoluble in water, slightly soluble in alcohol. Beeswax (produced by Shanghai Huashen Rehabilitation Equipment Co., Ltd.): slightly yellow, insoluble in water, slightly soluble in alcohol. Melting point: 62~72℃.

[0033] Petroleum ether (produced by Shanghai Lelu Chemical Co., Ltd.): Main ingredients: pentane and hexane. Appearance and properties: colorless transparent liquid with kerosene smell. Melting point <-73℃, boiling range 90-120℃. Solubility: insoluble in water, soluble in most organic solvents such as absolute ethanol and oil. Main use: Mainly used as a solvent and as a grease extraction.

[00...

Embodiment 2

[0060] The lubricating oil preparation method includes the following steps: raw materials: fatty acid esters (paraffin wax and beeswax each account for 50%), aliphatic solvents (petroleum ether 40% and 120# solvent each account for 60%) a, weighing 0.3% by weight Put the fatty acid esters into the heating reactor attached, and heat the reaction kettle to 70°C to fully melt the fatty acid esters; b. Weigh 99.7% by weight of the aliphatic solvent and add 5 times the weight of the fatty acid ester to the fat Add the solvent to the fatty acid ester solution in step a and stir until it is uniform and non-colloidal. Under this condition, add the remaining weight of the aliphatic solvent with a pump, and stir until the dissolution is complete; c. Put it into a clean oil drum with a seal and store it in a sealed container.

[0061] Experimental group: the lubricating oil of the present invention, the control group: previously used outsourcing lubricating oil and gasoline lubricating oil....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com