Hydrotalcite-ammonium polyphosphate halogen-free flame retardant and preparation method thereof

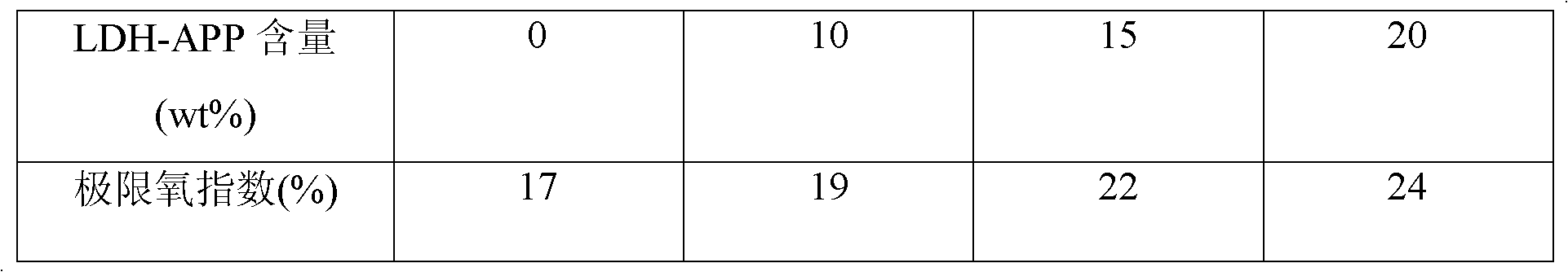

A technology of ammonium polyphosphate and hydrotalcite, applied in the field of halogen-free flame retardants and its preparation, can solve the problem of low flame retardant efficiency of inorganic flame retardants aluminum hydroxide and magnesium hydroxide, affecting the mechanical properties and processing flow of flame retardant materials In order to achieve the effects of improved mechanical properties and processing fluidity, good practicability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029](1) Place 3 g of commercially available hydrotalcite in 250 mL of 50% industrial alcohol, ultrasonicate at 50 Hz in an ultrasonic instrument (KQ-50B, Kunshan Ultrasonic Instrument Co., Ltd.) for 0.5 h, and then stir in a water bath at 60 ° C for 1 h to form a uniform suspension. turbid liquid;

[0030] (2) Weigh 3g of ammonium polyphosphate, add it into the hydrotalcite suspension in step (1) under continuous stirring, adjust the pH value of the solution to 4.0 with 1mol / L phosphoric acid, and keep stirring in a water bath at 60°C for 2h , filtered, the filter cake was first washed with 50% industrial alcohol, then washed with deionized water until neutral, dried at 70°C, and ground to obtain 3.313g of hydrotalcite-ammonium polyphosphate halogen-free flame retardant.

Embodiment 2

[0032] (1) Put 3 g of commercially available hydrotalcite (LDH) in 250 mL of 50% industrial alcohol, ultrasonically treat it in an ultrasonic instrument at 50 Hz for 0.5 h, and stir in a water bath at 60 ° C for 1 h to form a uniform suspension;

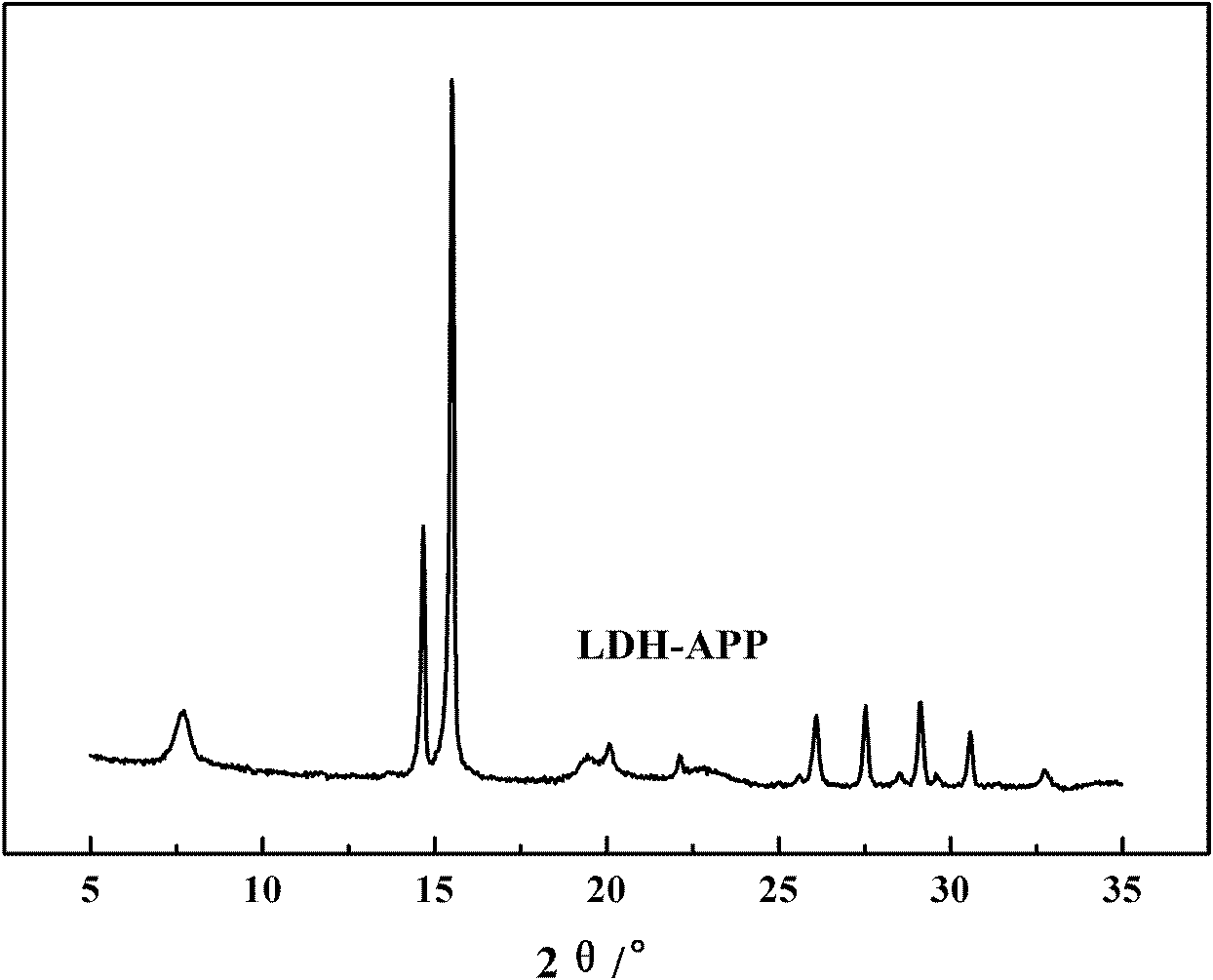

[0033] (2) Weigh 6g of ammonium polyphosphate (APP), and add it into the hydrotalcite suspension in step (1) under continuous stirring; adjust the pH value of the solution to 4 with 1mol / L phosphoric acid, and place it in a water bath at 60°C Continue to stir for 4 hours, filter, wash the filter cake with 50% industrial alcohol, then wash with deionized water until neutral, dry at 70°C, and grind to obtain 3.219g of hydrotalcite-ammonium polyphosphate halogen-free flame retardant (LDH-APP) , and carry out XRD spectrogram test to hydrotalcite-ammonium polyphosphate halogen-free flame retardant with X-ray diffractometer (X'Pert PRO, Holland PNAlytical company), the result is as follows figure 1 It can be seen that the interlayer spacin...

Embodiment 3

[0035] (1) Put 3 g of commercially available hydrotalcite in 250 mL of 50% industrial alcohol, sonicate for 0.5 h at 50 Hz in an ultrasonic instrument, and stir in a water bath at 70 ° C for 1 h to form a uniform suspension;

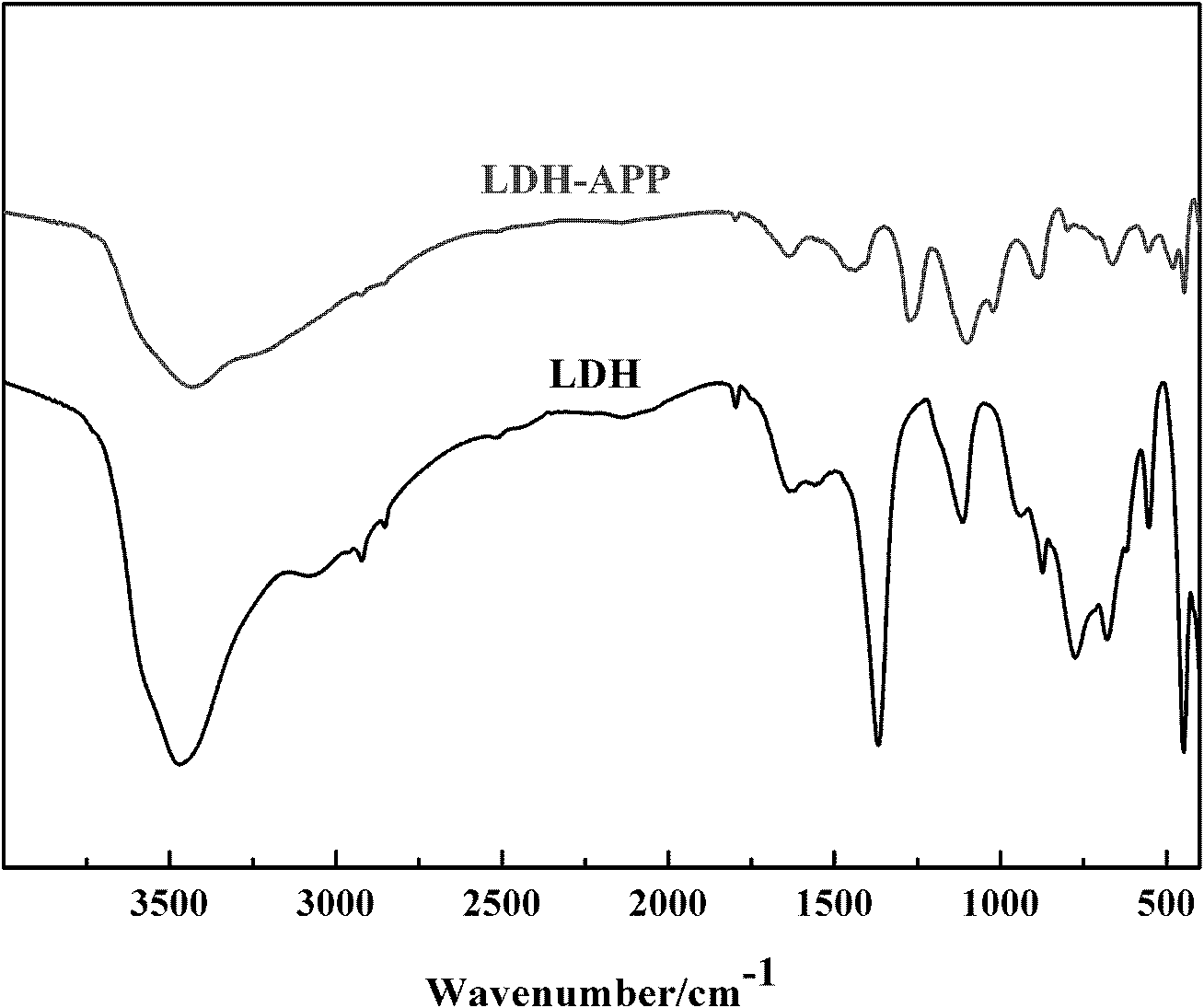

[0036] (2) Weigh 9g of ammonium polyphosphate, add it into the hydrotalcite suspension in step (1) under continuous stirring, adjust the pH value of the solution to 4.0 with 1mol / L phosphoric acid, and keep stirring in a water bath at 70°C for 6h , filtered, the filter cake was first washed with 50% industrial alcohol, then washed with deionized water to neutrality, dried at 70°C, ground to obtain 3.019g of hydrotalcite-ammonium polyphosphate halogen-free flame retardant, and used an infrared spectrometer (Nicolet 670, U.S. Nicoli Company) carried out infrared scanning on hydrotalcite-ammonium polyphosphate halogen-free flame retardant, the results are shown in figure 2 , compared with the infrared spectrum of raw material hydrotalcite (LDH), in the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com