Production of fatty poly-ester carbonate polyhydric alcohol

A polycarbonate and production process technology, applied in the field of carbon dioxide copolymer production, can solve the problems of poor mixing effect of the system, increased production cost, low product market competitiveness, etc., achieve high phase boundary area and mass transfer speed, no running And sealing parts, the effect of effective and uniform suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

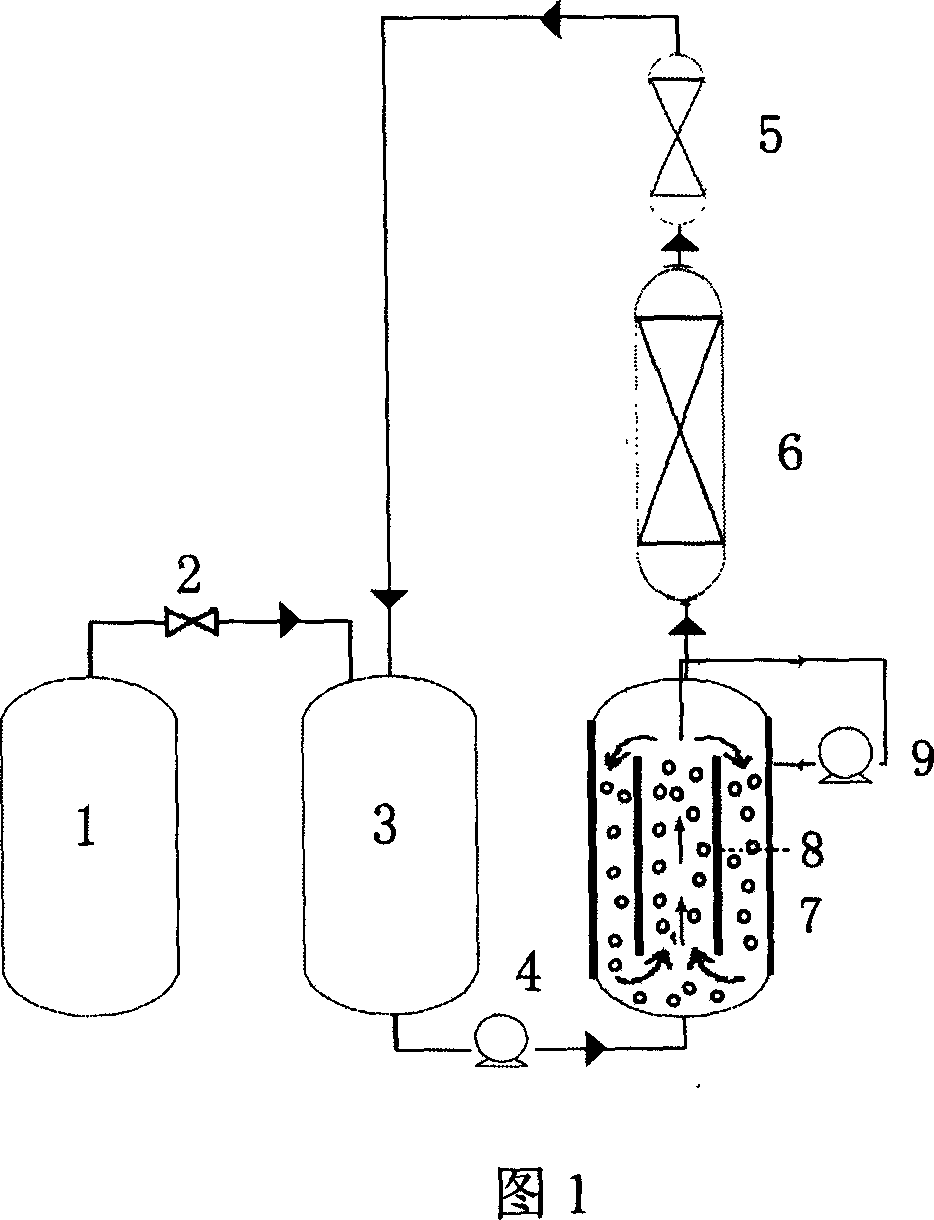

[0017] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Taking the loop reactor of a single draft tube as an example, the process of the present invention is further described: the diameter of the outer tube of the loop reactor used is 0.2 meters, the height of the reactor is 2 meters, the diameter of the inner draft tube is 0.14 meters, and the diameter of the draft tube is 0.14 meters. The height is 1.4 meters, and the whole device is shown in Figure 1.

[0018] The reaction adopts solventless polymerization, with 35kg according to the catalyst prepared according to CN 1044663A according to 1.6:4:100, polyether polyol (moisture content 300ppm) that is fully dried, molecular weight is 300, and average functionality is 3, propylene oxide Put it into the loop reactor, feed carbon dioxide to raise the pressure of carbon dioxide in the system to 4Mpa, start the liquid circulation pump to circulate the material in the system, and keep the temperature of the reaction material at 60...

Embodiment 2

[0020] Using the polymerization device described in Example 1, using solvent polymerization, 40 kg of the catalyst prepared according to CN 1044663A according to 1.6:3:30:100, fully dried polyether polyether with a molecular weight of 300 and an average functionality of 3 Alcohol (moisture content 300ppm), toluene, propylene oxide, etc. are added to the loop reactor. Other operations are as in Example 1.

[0021] After 12 hours of reaction, the product was discharged. The molecular weight of the product was 5210, the carbonate group content in the product was 37%, and the by-product propylene carbonate content was 15.2%.

Embodiment 3

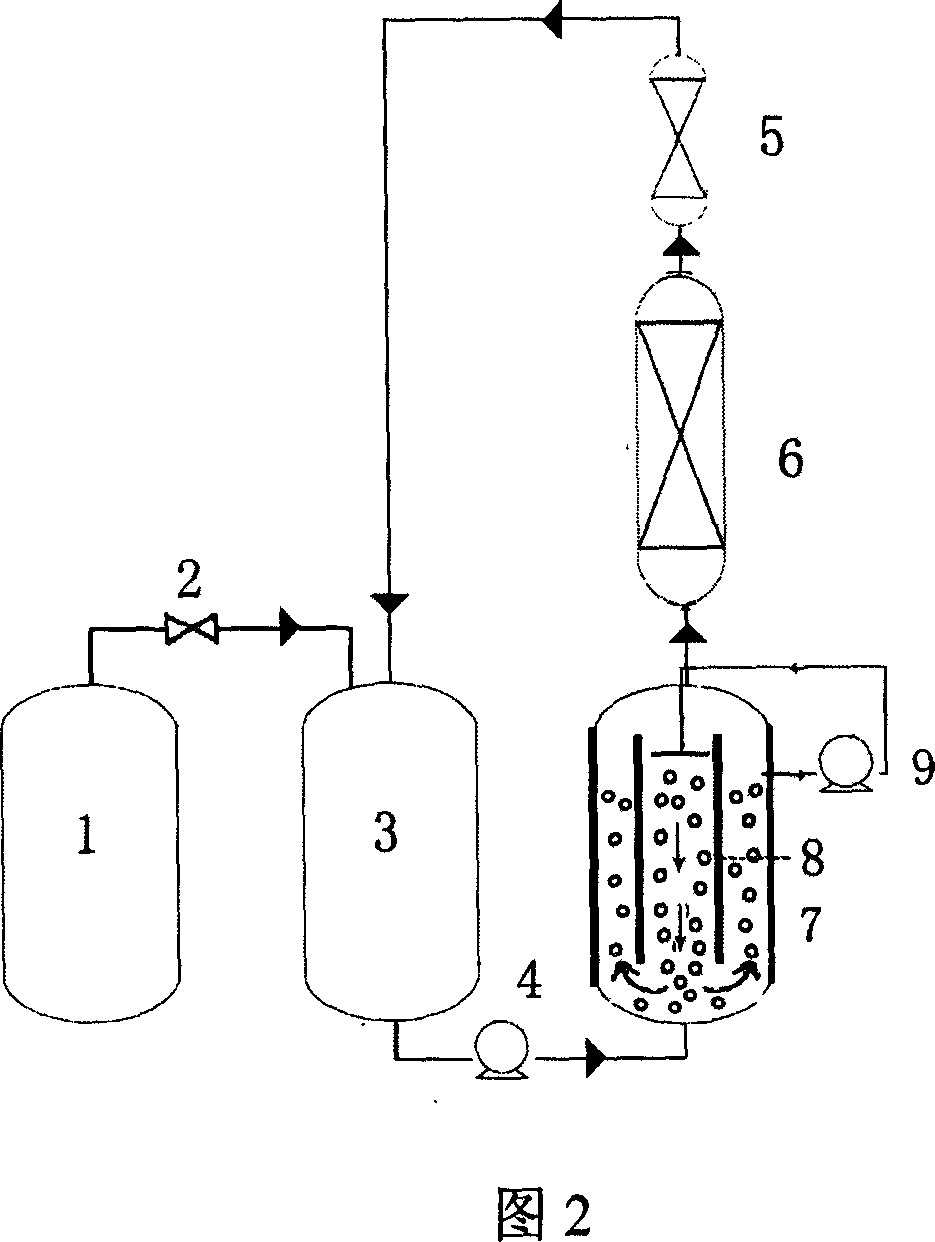

[0023] The loop reaction adopts the device shown in Figure 2.

[0024] The reaction adopts solvent-free system polymerization, with 35kg according to the catalyst prepared according to CN 1044663A according to 1.6:5:100, polyether polyol (moisture content 300ppm) that is fully dried, molecular weight is 300, and average functionality is 3, epoxy resin Add propane, etc. into the loop reactor, feed carbon dioxide to increase the pressure of carbon dioxide in the system to 4Mpa, start the liquid circulation pump to circulate the material in the system, and keep the temperature of the reaction material at 60°C by adding jackets and internal heat exchange tubes. Turn on the carbon dioxide compressor, adjust the flow rate of carbon dioxide, keep the concentration of carbon dioxide in the diversion barrel and outside the diversion barrel constant, and discharge the material after 12 hours of reaction. The molecular weight of the product is 3850, the carbonate group content in the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com