Vertical light wine solid-state continuous fermentation equipment and process

A technology of fermentation equipment and vertical fermentation tank, which is applied in the direction of fermentation, preparation of alcoholic beverages, biochemical equipment and methods, etc. It can solve the problems of difficulty in realizing large-scale production, large equipment footprint, and high energy consumption for drum rotation. Achieve the effects of overcoming the lack of saccharifying power, increasing the yield and reducing the residual sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

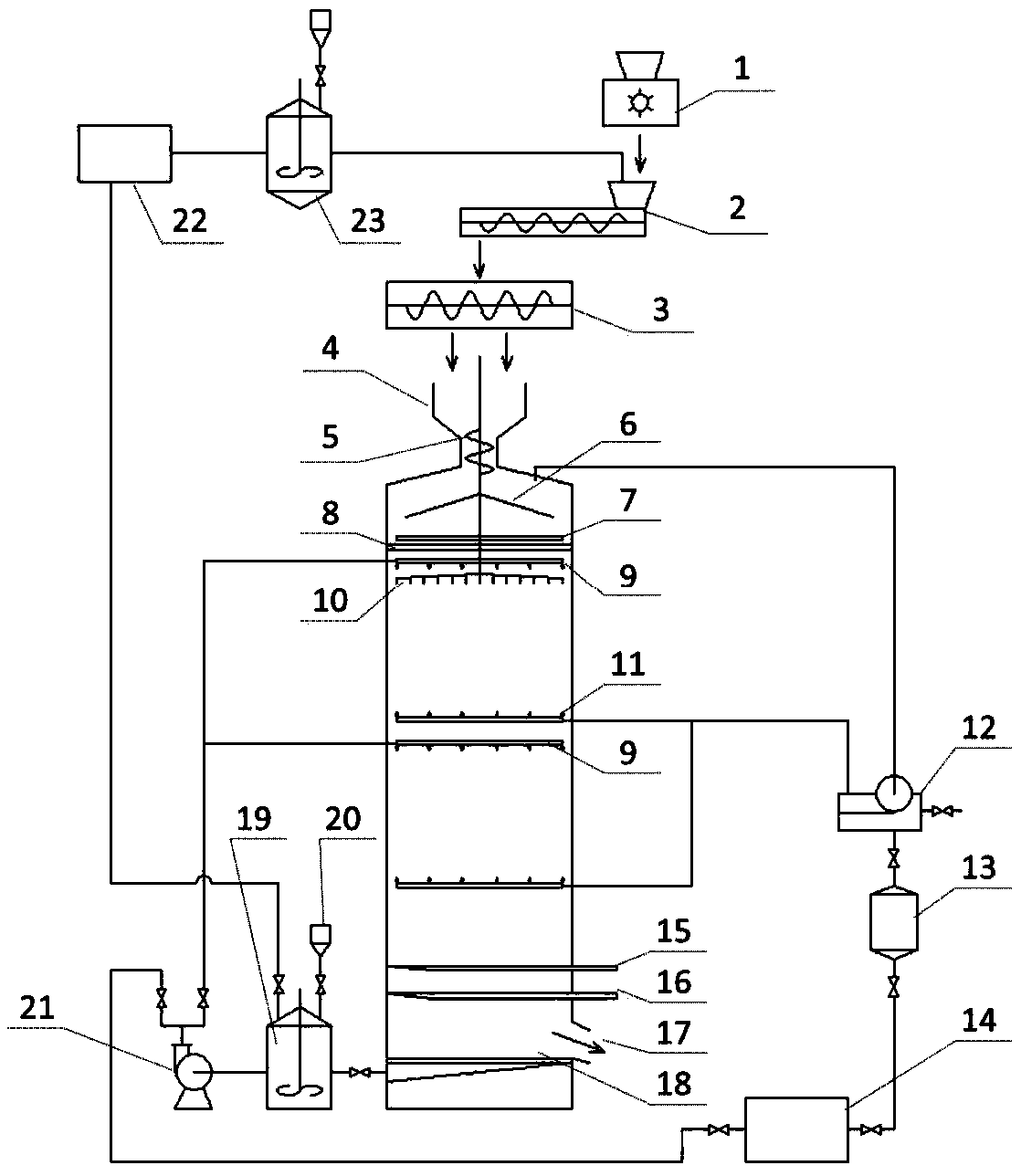

[0030] The structure of the vertical solid light wine continuous fermentation equipment of the present invention refers to the attached figure 1 As shown in , the whole set of equipment mainly includes feeding system, vertical fermentation tank, slurry system, CO2 circulating cooling system and wine steaming device, and each device is connected to each other through pipelines and pump bodies.

[0031] Wherein, the feeding system includes a pulverizer (1) and a conveying auger (2) and a ribbon mixer (3) below. The outlet of the ribbon mixer (3) is facing the hopper (4) of the vertical fermenter; the hopper (4) is provided with a feeding auger (5), and below it is a distribution cap (6), a sieve plate (8 ), a distributing device consisting of a rake (10) for leveling materials; holes are arranged on the distributing cap, and a scraper (7) is provided on the sieve plate. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com