A vertical continuous fermentation device for silkworm excrement

A fermentation device, vertical technology, applied in silkworm excrement vertical continuous fermentation device, fertilizer processing equipment field, can solve the problems of unstable product quality, large occupied area, low production efficiency, etc., achieve small occupied area, high equipment The effect of less investment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

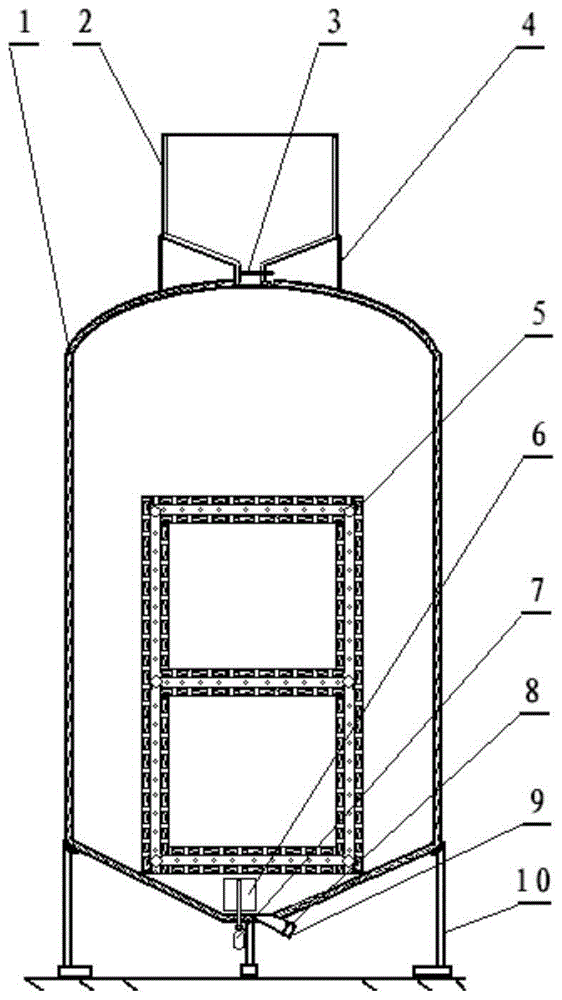

[0025] A vertical continuous fermentation device for silkworm excrement, which is provided with a tank body 1 and a storage tank 2, and is characterized in that: the top of the tank body 1 is provided with a storage tank 2 and a feeding control panel 3, and the middle section of the tank body 1 and the The lower section is provided with a temperature equalizing guide 5, and the bottom of the tank body 1 is provided with a material bracket 6, a discharge port 9 and a material discharge control panel 8, and the adjustment between the material bracket 6 and the bottom outer wall of the tank body 1 is arranged. Speed motor 7 is connected, and the bottom of tank body 1 is also provided with fixed foot 10.

[0026] The temperature equalizer 5 is welded by 4 vertical pipes and 12 horizontal pipes, the vertical pipes and the horizontal pipes are connected to each other, and some small air holes are arranged on the walls of the vertical pipes and horizontal pipes.

[0027] The four c...

Embodiment 2

[0033] A vertical continuous fermentation device for silkworm excrement, which is provided with a tank body 1 and a storage tank 2, and is characterized in that: the top of the tank body 1 is provided with a storage tank 2 and a feeding control panel 3, and the middle section of the tank body 1 and the The lower section is provided with a temperature equalizing guide 5, and the bottom of the tank body 1 is provided with a material bracket 6, a discharge port 9 and a material discharge control panel 8, and the adjustment between the material bracket 6 and the bottom outer wall of the tank body 1 is arranged. Speed motor 7 is connected, and the bottom of tank body 1 is also provided with fixed foot 10.

[0034] The temperature equalizer 5 is welded by 3 vertical pipes and 6 horizontal pipes, the vertical pipes and horizontal pipes are connected to each other, and a number of small air holes are arranged on the surrounding walls of the vertical pipes and horizontal pipes.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com