Process for producing roxburgh rose distilled liquor

A technology of distilled wine and thorn pear, which is applied in the field of production of thorn pear distilled wine, can solve the problems of poor control of fermentation temperature, low liquor yield, high material cost, etc., and achieve fresh and elegant fruity aroma, strong fruity aroma but not Floatation, the effect of low fermentation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

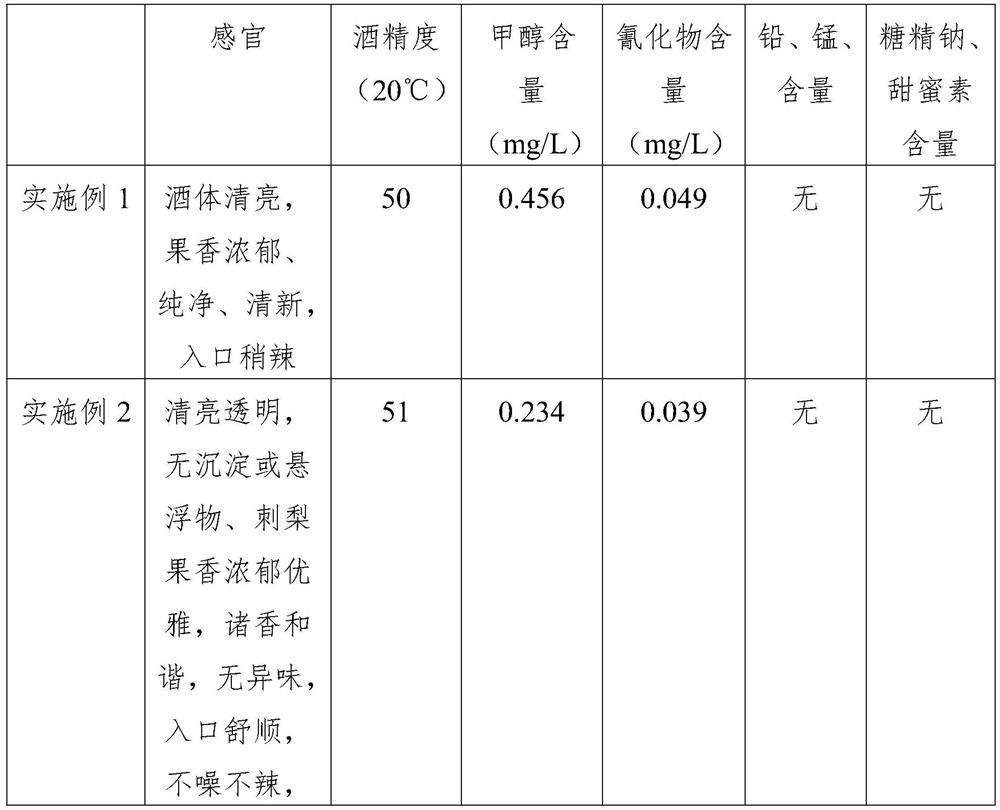

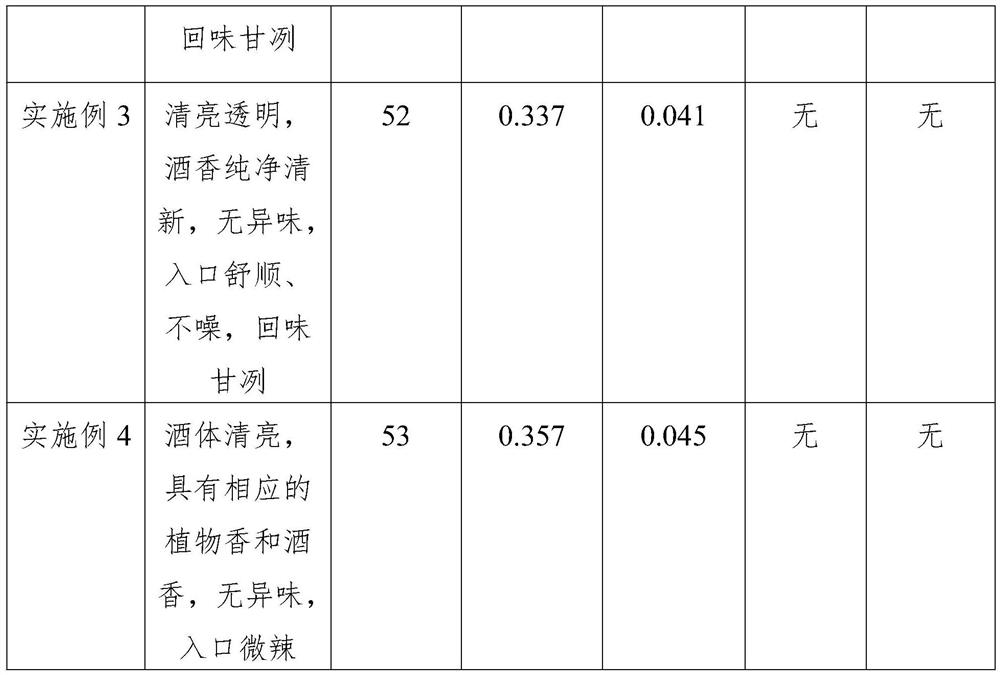

Examples

Embodiment 1

[0031] The invention provides a process for producing Rosa roxburghii distilled wine, the specific steps are as follows:

[0032] Step 1, raw material selection: the raw materials used (by weight) include 70 parts of Rosa roxburghii, 10 parts of Schisandra chinensis, 5 parts of Salvia miltiorrhiza, and 5 parts of mulberry;

[0033] Step 2. Cleaning: Clean the dust and impurities of prickly pear, Schisandra chinensis, Salvia miltiorrhiza and mulberry, and remove rotten fruit;

[0034] Step 3, crushing and putting into the tank: use a crusher to simply crush the prickly pear, schisandra, salvia miltiorrhiza, and mulberry and put them into the fermentation tank.

[0035] Step 4, solid-liquid fermentation: Add drinking water at a ratio of 1:1 of the weight of Rosa roxburghii, and then add yeast and yeast fermentation nutrient. The amount of yeast added is 400g / ton of water, and the amount of yeast fermented nutrient is 400g / ton of water , cycle twice a day, and the fermentation t...

Embodiment 2

[0040] The invention provides a process for producing Rosa roxburghii distilled wine, the specific steps are as follows:

[0041] Step 1, raw material selection: the raw materials used (in parts by weight) include 75 parts of Rosa roxburghii, 15 parts of Schisandra chinensis, 10 parts of Salvia miltiorrhiza, and 10 parts of mulberry;

[0042] Step 2. Cleaning: Clean the dust and impurities of prickly pear, Schisandra chinensis, Salvia miltiorrhiza and mulberry, and remove rotten fruit;

[0043] Step 3, crushing and putting into tanks: use a crusher to simply crush thorn pears, schisandra, salvia miltiorrhiza, and mulberry, and then put them into the fermentation tank.

[0044]Step 4, solid-liquid fermentation: Add drinking water at a ratio of 1:1 of the weight of Rosa roxburghii, and then add yeast and yeast fermentation nutrient. The amount of yeast added is 400g / ton of water, and the amount of yeast fermented nutrient is 400g / ton of water , cycle twice a day, and the fermen...

Embodiment 3

[0049] The invention provides a process for producing Rosa roxburghii distilled wine, the specific steps are as follows:

[0050] Step 1, raw material selection: the raw materials used (in parts by weight) include 80 parts of Rosa roxburghii, 20 parts of Schisandra chinensis, 15 parts of Salvia miltiorrhiza, and 15 parts of mulberry;

[0051] Step 2. Cleaning: Clean the dust and impurities of prickly pear, Schisandra chinensis, Salvia miltiorrhiza and mulberry, and remove rotten fruit;

[0052] Step 3, crushing and putting into tanks: use a crusher to simply crush thorn pears, schisandra, salvia miltiorrhiza, and mulberries and put them into the fermentation tank. The amount of crushed thorn pears, schisandra, danshen and mulberries in the tank is 65% of the tank capacity;

[0053] Step 4, solid-liquid fermentation: Add drinking water at a ratio of 1:1 of the weight of Rosa roxburghii, and then add yeast and yeast fermentation nutrient. The amount of yeast added is 400g / ton of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com