A solid-liquid separation fermentation treatment tank for township garbage

A solid-liquid separation and treatment pool technology, applied in the direction of organic fertilizers, climate change adaptation, etc., can solve problems such as unstable temperature in the furnace, waste of resources, insufficient garbage incineration, etc., to control and reduce environmental pollution and prevent harmful substances The effect of improving the rural ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

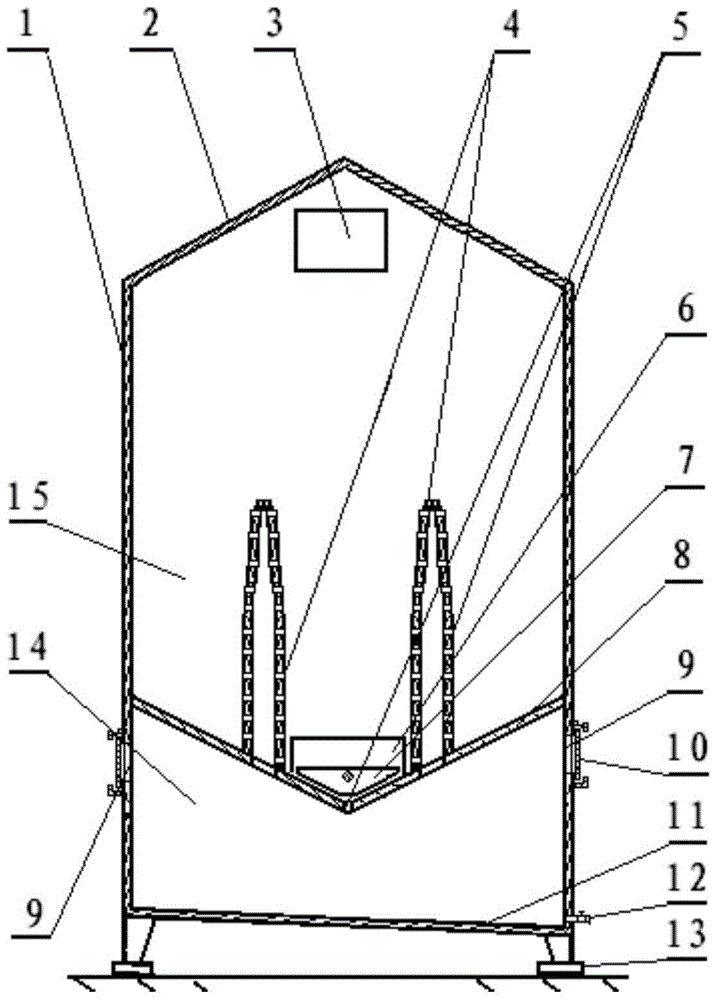

[0023] A solid-liquid separation fermentation treatment pool for township garbage, which includes a pool body 1, the pool body 1 is a cube, and a V-shaped partition 8 is arranged in the lower section of the pool body 1 to form a solid fermentation room 15 and a liquid fermentation room 14. The top of the pool body 1 is provided with an inverted V-shaped top plate 2, and the upper end of the pool body 1 is provided with a garbage outlet 3. The V-shaped partition 8 is fixed to the four sides of the pool body 1, and the inside of the V-shaped partition 8 can be set. Long rake for pulling and pushing7.

[0024] The lower part of the above-mentioned solid fermentation chamber 15 is provided with a solid discharge port 6 , the solid discharge port 6 is provided with a movable door panel 10 , and the solid discharge port 6 is arranged at both ends of the V-shaped partition 8 .

[0025] The pool bottom 11 of the above-mentioned liquid fermentation chamber 14 is a slant plate, the four...

Embodiment 2

[0032] A solid-liquid separation fermentation treatment pool for township garbage, which includes a pool body 1, the pool body 1 is a cuboid, and a V-shaped partition 8 is arranged in the lower section of the pool body 1 to form a solid fermentation room 15 and a liquid fermentation room 14. The top of the pool body 1 is provided with an inverted V-shaped top plate 2, and the upper end of the pool body 1 is provided with a garbage outlet 3. The V-shaped partition 8 is fixed to the four sides of the pool body 1, and the inside of the V-shaped partition 8 can be set. Long rake for pulling and pushing7.

[0033] The lower part of the above-mentioned solid fermentation chamber 15 is provided with a solid discharge port 6 , the solid discharge port 6 is provided with a movable door panel 10 , and the solid discharge port 6 is arranged at both ends of the V-shaped partition 8 .

[0034] The pool bottom 11 of the above-mentioned liquid fermentation chamber 14 is a slant plate, the fo...

Embodiment 3

[0041] A solid-liquid separation fermentation treatment pool for township garbage, which includes a pool body 1, the pool body 1 is a cuboid, and a V-shaped partition 8 is arranged in the lower section of the pool body 1 to form a solid fermentation room 15 and a liquid fermentation room 14. The top of the pool body 1 is provided with an inverted V-shaped top plate 2, and the upper end of the pool body 1 is provided with a garbage outlet 3. The V-shaped partition 8 is fixed to the four sides of the pool body 1, and the inside of the V-shaped partition 8 can be set. Long rake for pulling and pushing7.

[0042] The lower part of the above-mentioned solid fermentation chamber 15 is provided with a solid discharge port 6 , the solid discharge port 6 is provided with a movable door panel 10 , and the solid discharge port 6 is arranged at both ends of the V-shaped partition 8 .

[0043]The pool bottom 11 of the above-mentioned liquid fermentation chamber 14 is a slant plate, the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com