Solid-liquid two-phase herbal tea residue fermentation process and application thereof

A technology of liquid fermentation and solid state fermentation, applied in the field of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

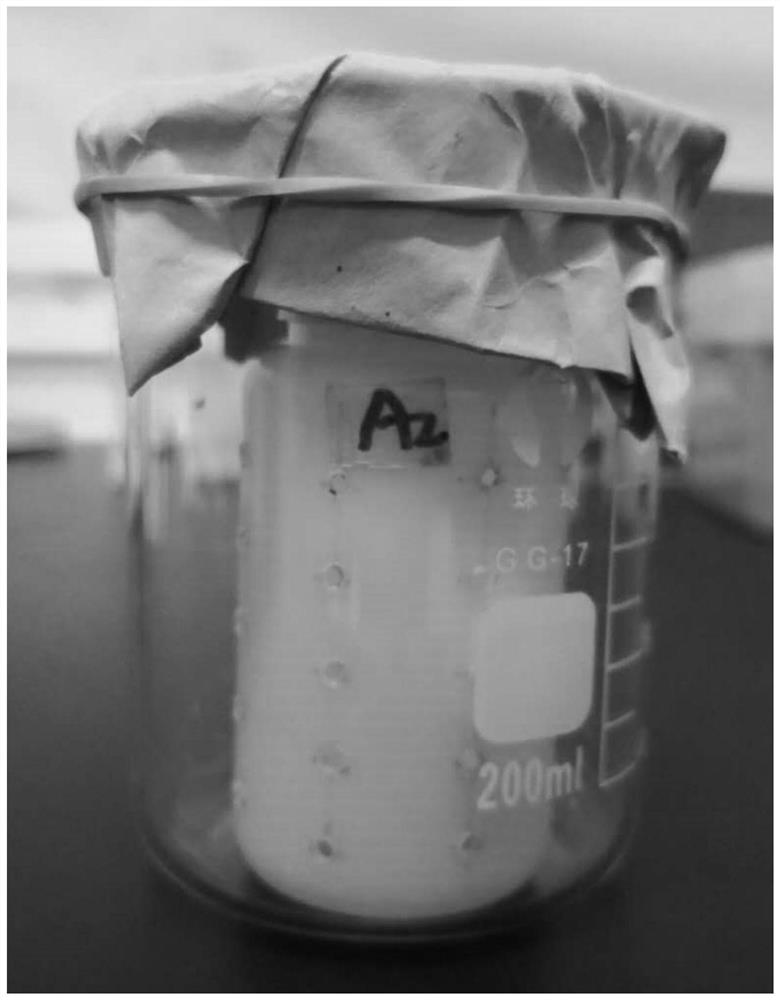

[0037] Embodiment 1 solid-liquid two-phase fermentation device

[0038] An example of a solid-liquid two-phase fermentation device in the present invention, specifically as figure 1 shown.

[0039] The manufacturing method of this solid-liquid two-phase fermentation device is:

[0040] Take a 50mL plastic bottle with a height of 6.8cm and a diameter of 4.2cm, start from the bottom 1cm, at intervals of 1cm in height and 1.7cm in arc length, make 8 rows of 5 holes of the same size, and the diameter of the holes is about 1mm.

[0041] After tightening the bottle cap, put it into a 200mL beaker and wrap it with newspaper or kraft paper to obtain a solid-liquid two-phase fermentation device.

Embodiment 2

[0042] Embodiment 2 A kind of solid-liquid two-phase herbal tea dregs fermentation method

[0043] A fermentation culture solution containing 1% ammonium sulfate, 0.1% dipotassium hydrogen phosphate and 0.125% potassium dihydrogen phosphate is prepared and sterilized under high pressure. Take 60g of fermentation culture liquid, add 15g of herbal tea dregs, soak for about 10min, and stir evenly.

[0044] The herbal tea dregs soaked are divided into 3 fermenting devices described in Example 1, each about 25g, and weighed accurately. Sterilize.

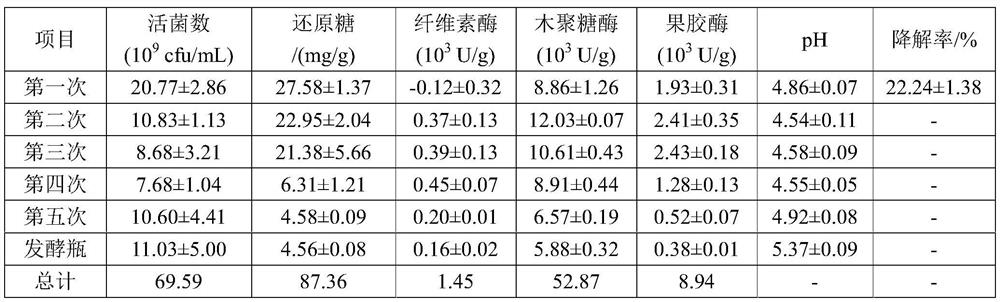

[0045] After sterilization, inoculate Aspergillus niger, strain concentration 2×10 9 cfu / mL, the inoculum volume was 10%. Add about 45mL of sterilized fermentation culture solution, so that two rows of holes in the plastic bottle are immersed in the nutrient solution, and then culture at 34°C and 80% humidity. At intervals of 2 days, the culture solution in the beaker was collected. After the medium in the plastic bottle was stirred...

Embodiment 3

[0052] Embodiment 3 A kind of solid-liquid two-phase herbal tea dregs fermentation method

[0053] A fermentation culture solution containing 1% ammonium sulfate, 0.1% dipotassium hydrogen phosphate and 0.125% potassium dihydrogen phosphate is prepared and sterilized under high pressure. Take 60g of fermentation culture liquid, add 15g of herbal tea dregs, soak for about 10min, and stir evenly.

[0054] The herbal tea dregs soaked are divided into 3 fermenting devices described in Example 1, each about 25g, and weighed accurately. Sterilize.

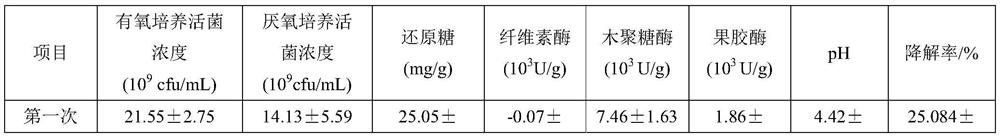

[0055] After sterilization, inoculate Aspergillus niger and Lactobacillus casei, strain concentration 2×10 9 cfu / mL, the inoculum volume was 10%. Add about 45mL of sterilized fermentation culture solution, so that two rows of holes in the plastic bottle are immersed in the nutrient solution, and then culture at 34°C and 80% humidity. At intervals of 2 days, the culture solution in the beaker was collected. After the medium in the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com