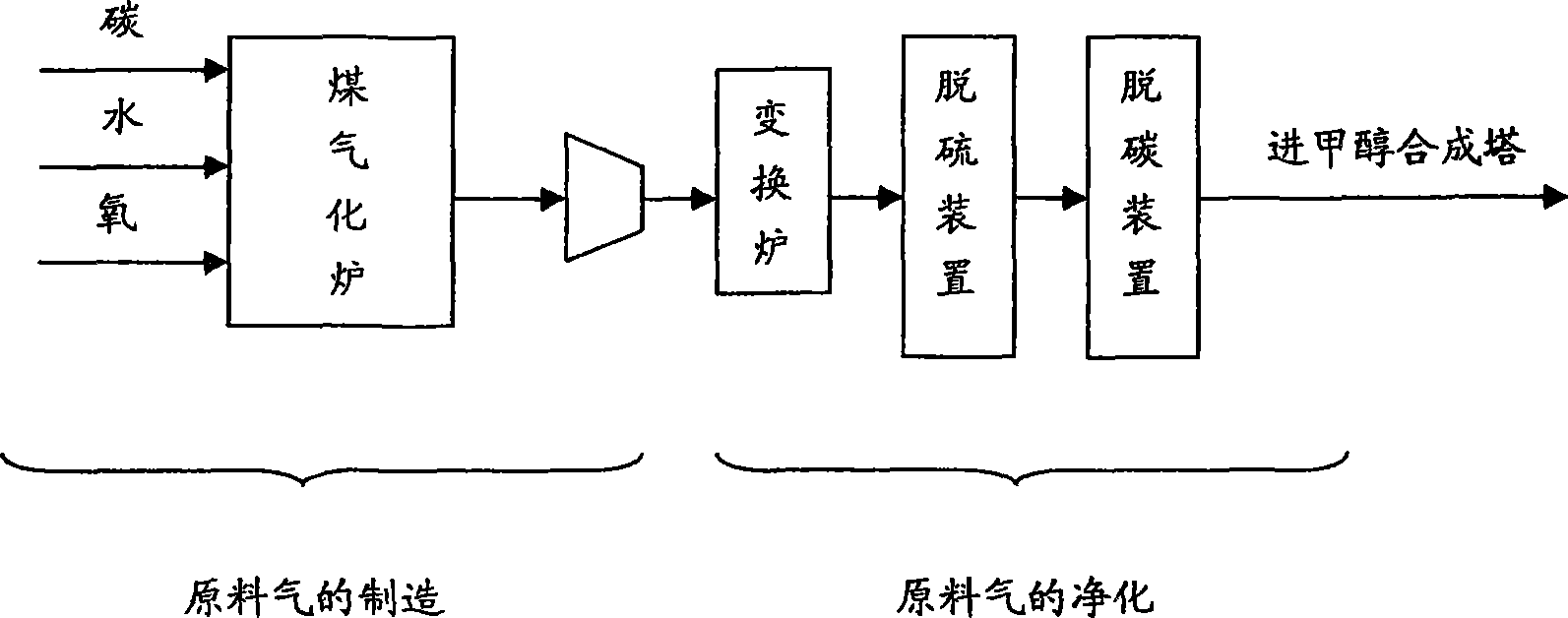

Method for directly applying large scale non-grid connected wind power to methyl alcohol production

A large-scale, wind power technology, applied in chemical instruments and methods, electrolysis processes, electrolysis components, etc., can solve the problems of increasing wind turbine manufacturing costs and wind power prices, unstable wind power, and large energy consumption, reducing equipment investment and cost. Low operating costs, less environmental and ecological disturbance, and reduced water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

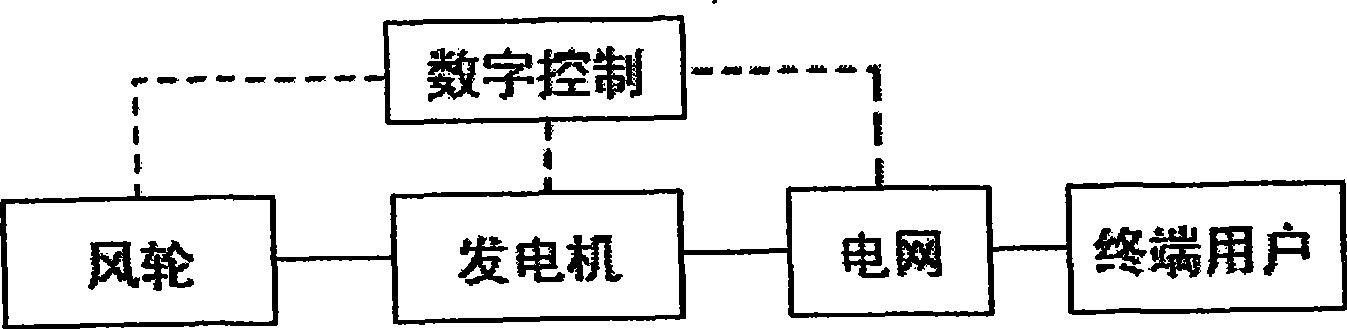

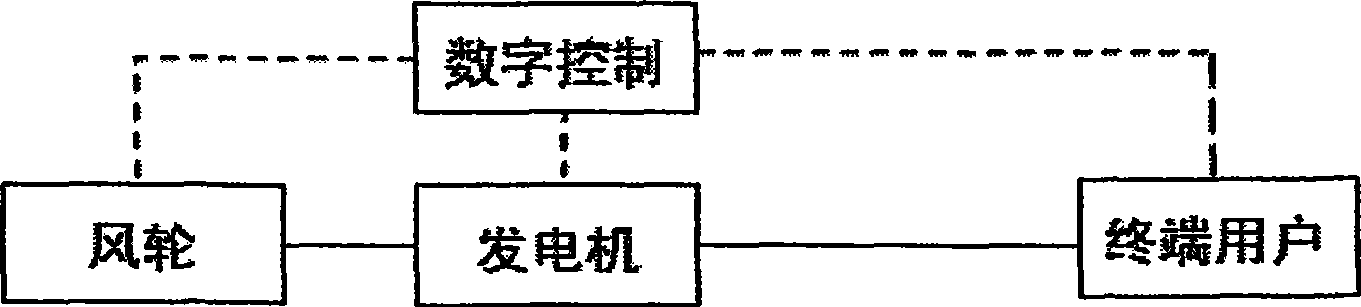

[0046] Referring to Fig. 3, 1 in the figure is carbon flow; 2 is water flow; 3 is oxygen flow; 4 is coal gasifier; 5 is compressor; 6 is heat exchanger; 7 is desulfurization device; 8 is wind energy; 9 is 10 is an electrolysis equipment; 11 is an oxygen storage tank; 12 is an oxygen compressor; 13 is a hydrogen storage tank; 14 is a hydrogen compressor; 15 is a heat exchanger; 16 is a flow regulating valve; 17 is an online detection device; 18 is the water gas stream with the best carbon-to-hydrogen ratio; 19 is the methanol synthesis tower; 20 is crude methanol.

[0047] In conjunction with the process flow chart of Fig. 3, the present invention is explained through the following examples.

[0048] The wind energy is transformed into randomly changing pulsating direct current through 100 1500KW wind turbines. The wind turbines can be purchased from Goldwind 70 / 1500 simplified type produced by Goldwind Technology Co., Ltd. Transformer), direct output direct current, its techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com