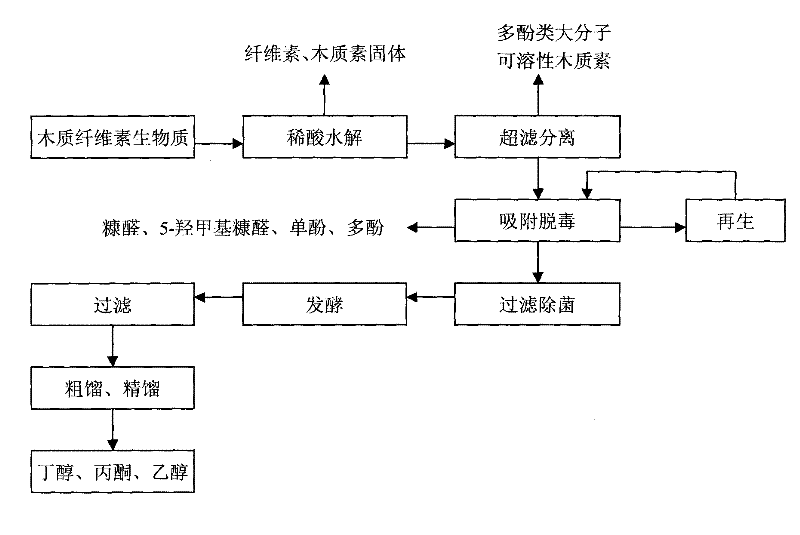

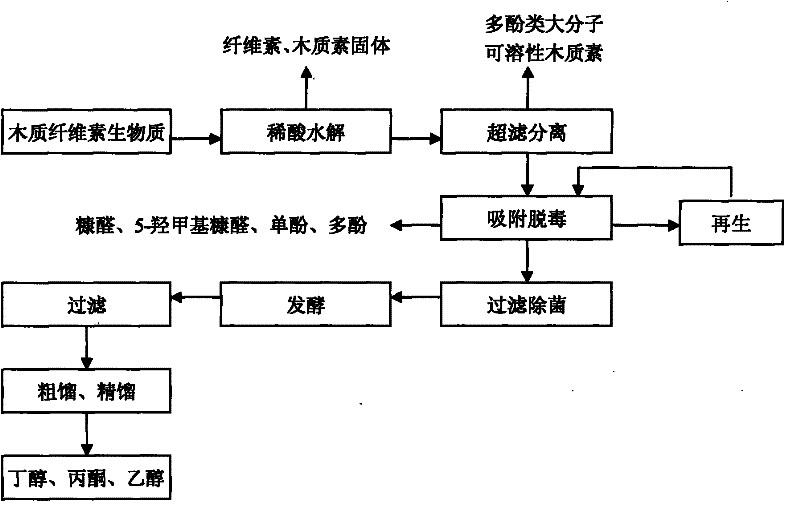

Method for fermenting and preparing biological butyl alcohol by using lignocellulose biomass as raw material

A lignocellulosic and bio-butanol technology, applied in the field of bioengineering, can solve problems such as unfavorable fermentation by fermentation inhibitors, and achieve the effects of reducing fermentation energy consumption, promoting income increase, and realizing sustainable utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]Butanol is prepared by fermenting corn stalks as raw material. Dilute acid hydrolysis conditions are: 2% (v / v) sulfuric acid solution, the ratio of raw material to dilute acid is 18% (w / v), and the hydrolysis temperature is 121°C. The hydrolysis time is 120min, the hydrolyzate is filtered, the sulfate radical in the filtrate is neutralized with milk of lime, the precipitate is filtered off, and the supernatant is concentrated to a total reducing sugar concentration of 150g / L.

[0025] To detoxify the hydrolyzed sugar solution, firstly, the organic ultrafiltration membrane with a molecular weight cut-off of 5000 Daltons is used to separate the hydrolyzed sugar solution, the operating pressure is 0.3Mpa, pH5.0, and the operating temperature is 25°C. Porous adsorption resin fixed bed adsorption detoxification, pH 5.0, temperature 25°C, the volume of the treated hydrolyzed sugar solution is 15 times the volume of the resin bed. After the above treatment, the removal rate of ...

Embodiment 2

[0032] Use bagasse as raw material to ferment butanol, dilute acid hydrolysis conditions are: 1.5% (v / v) of sulfuric acid, the ratio of raw material to dilute acid to liquid is 15% (w / v), hydrolysis temperature is 126°C, acid The hydrolysis time is 90 minutes, the hydrolyzate is filtered, the sulfate radical in the filtrate is neutralized with milk of lime, the precipitate is filtered off, and the supernatant is concentrated to a total reducing sugar concentration of 200g / L.

[0033] To detoxify the hydrolyzed sugar solution, firstly, the organic ultrafiltration membrane with a molecular weight cut-off of 1500 Daltons is used to separate the hydrolyzed sugar solution. The operating pressure is 0.5Mpa, pH4.5, and the operating temperature is 30°C. Porous adsorption resin fixed bed adsorption detoxification, pH 4.5, temperature 25 ° C, the volume of the treated hydrolyzed sugar solution is 20 times the volume of the resin bed, activated carbon adsorption is carried out on the sug...

Embodiment 3

[0041] Fermentation of butanol with corncobs as raw material, dilute acid hydrolysis conditions of corn stalks: 3% (v / v) sulfuric acid, 20% (w / v) solid-liquid ratio of raw materials and dilute acid, hydrolysis temperature 130°C , the acid hydrolysis time is 180min, the hydrolyzate is filtered, the sulfate in the filtrate is neutralized with milk of lime, the precipitate is filtered off, and the supernatant is concentrated to a total reducing sugar concentration of 150g / L. To detoxify the hydrolyzed sugar solution, the hydrolyzed sugar solution is first separated by a ceramic ultrafiltration membrane with a molecular weight cut-off of 5000 Daltons. The operating pressure is 0.3Mpa, pH5.0, and the operating temperature is 25°C. The filtrate is collected and then passed through The regenerated macroporous adsorption resin is fixed-bed adsorption detoxification, pH 4.0, temperature 25°C, and the volume of the treated hydrolyzed sugar solution is 25 times the volume of the resin bed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com