Catalyst used for increasing selectivity of higher carbon alcohol production via Fischer-Tropsch synthesis, and preparation method and applications thereof

A catalyst and selective technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve problems such as lack of high added value, restricted economy, and high proportion of methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

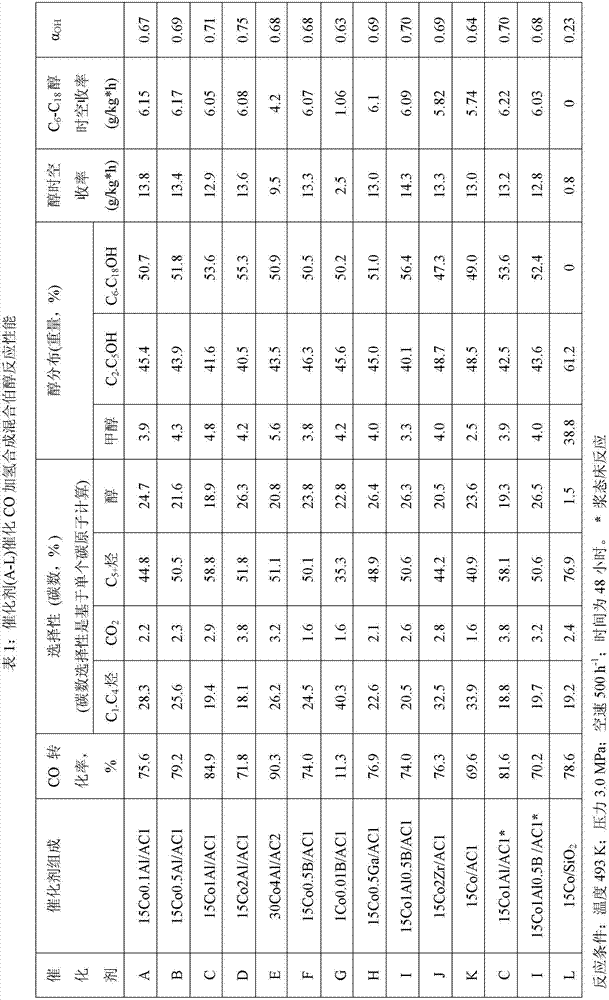

Examples

Embodiment 1

[0068] The specific surface area and pore size distribution of coconut shell activated carbon were measured on the AS-1 adsorption instrument of QUANTACHROME Company. The sample was first degassed at 573K for 3 hours, and nitrogen adsorption test was carried out at the temperature of liquid nitrogen, N 2 Molecular cross-sectional area is taken as 0.162nm 2 . The BET method was used to calculate the specific surface area of the samples, and the BJH method was used to calculate the pore distribution. The measured specific surface area of coconut shell activated carbon is 1012m 2 / g, the average pore diameter is 3.5nm, and the pore volume is 0.42mL / g.

[0069] Take 1000 grams of coconut shell activated carbon carrier, and use deionized water to boil and wash for three times. The specific method is: take 1000 grams of coconut shell activated carbon, add 5000 grams of deionized water, boil together for 0.5 hours, and then separate the activated carbon from the boiling water....

Embodiment 2

[0072] Catalyst B has a composition of 15Co0.5Al / AC1. Using the coconut shell activated carbon treated in Example 1 as a carrier, the catalyst was prepared according to the following steps. Weigh 10 grams of processed activated carbon and place it in a suction filter bottle. Weigh 0.822 g of Al(NO 3 ) 3 9H 2 O and 8.7 g Co(NO 3 ) 2 ·6H 2 O, they were dissolved in 10 mL deionized water to make a solution, and placed in a separatory funnel. Use a rubber stopper with a hole in the middle to seal the separatory funnel with the conical suction flask. The prepared solution is impregnated on the activated carbon by vacuum impregnation, that is, at room temperature, close the separatory funnel plunger, first treat the activated carbon under vacuum (0.01MPa) for 20 minutes, then open the plunger to remove the solution in the separatory funnel Flow into the activated charcoal in the suction flask so that it soaks in the solution. The prepared sample was dried in the shade at ro...

Embodiment 3

[0074] The composition of catalyst C is 15Co1Al / AC1. Using the coconut shell activated carbon treated in Example 1 as a carrier, the catalyst was prepared according to the following steps. Take by weighing 10 grams of activated carbon, take by weighing 1.65 grams of Al(NO 3 ) 3 9H 2 O and 5.53 g CoC 2 o 4 2H 2 O was prepared into a solution in 13 mL of deionized water, and the prepared solution was impregnated on activated carbon by the above-mentioned conventional impregnation method. Dry in the shade at room temperature, the drying time is based on the time when the catalyst reaches a dry state, then dry in an air atmosphere at 343K for 24 hours, then dry in an argon atmosphere at 383K for 4 hours; finally dry in an argon atmosphere at 623K Calcined for 4 hours to obtain a catalyst C oxide precursor with a Co weight content of 15% and an Al weight content of 1%. The BET determination of catalyst C oxide precursor is the same as above, and its specific surface area is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com