Technology and device for producing high-purity ethyl alcohol

An ethanol, high-purity technology, applied in the chemical industry, can solve the problems of reducing the adsorption efficiency of molecular sieves, destroying the lattice structure of molecular sieves, and high energy consumption of molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

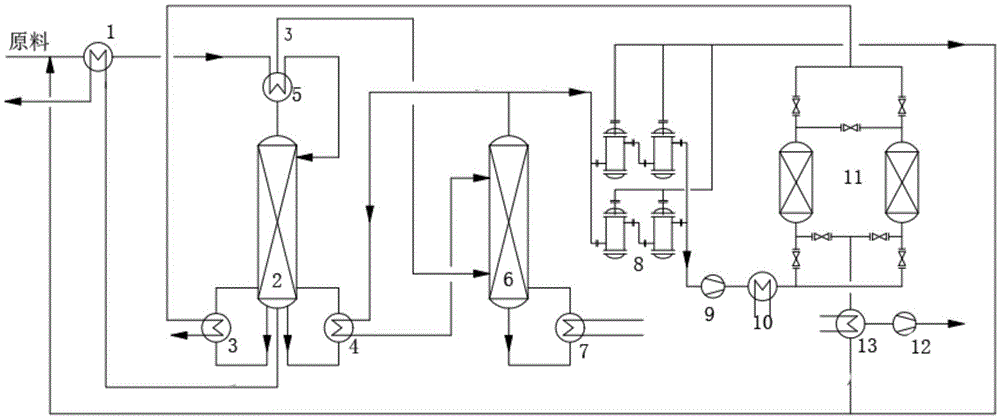

[0047] Such as figure 1 Shown, the low-concentration ethanol mother liquor of ethanol content 20wt.% enters the top of low-pressure rectification tower 2 after the tower bottom liquid of low-pressure rectification tower 2, tower top crude distillate steam preheating, after rectification, tower still obtains Residue, steam with an ethanol content of 50wt.% is obtained at the top of the tower, and the steam is used to preheat the raw materials. The steam after the preheated raw materials enters the pressurized rectification tower 6. After rectification, the ethanol content of the tower reactor is ≤0.1 wt.% waste water, ethanol content 80wt.% positive pressure stream steam is obtained at the top of the tower, the positive pressure ethanol stream is divided into two streams, the mass ratio of the two streams returning to the pressurized rectification tower and entering the pervaporation membrane is 2:1, The stream returning to the pressurized rectification tower exchanges heat wit...

Embodiment 2

[0050] Such as figure 1 Shown, the low-concentration ethanol mother liquor of ethanol content 25wt.% enters the top of low-pressure rectification tower 2 after the tower bottom liquid of low-pressure rectification tower 2, tower top crude distillate steam preheating, after rectification, tower still obtains Residue, steam with an ethanol content of 57wt.% is obtained at the top of the tower, and the steam is used to preheat the raw materials. The steam after the preheated raw materials enters the pressurized rectification tower 6. After rectification, the ethanol content of the tower reactor is ≤0.1 wt.% waste water, ethanol content 85wt.% positive pressure stream steam is obtained at the top of the tower, the positive pressure ethanol stream is divided into two streams, the mass ratio of the two streams returning to the pressurized rectification tower and entering the pervaporation membrane is 3:1, The stream returning to the pressurized rectification tower exchanges heat wit...

Embodiment 3

[0053] The difference from Example 2 is that the permeate from the pervaporation membrane 8 can also be returned to the pressurized rectification column 6 for feeding.

[0054] Such as figure 1 Shown, the low-concentration ethanol mother liquor of ethanol content 25wt.% enters the top of low-pressure rectification tower 2 after the tower bottom liquid of low-pressure rectification tower 2, tower top crude distillate steam preheating, after rectification, tower still obtains Residue, steam with an ethanol content of 62wt.% is obtained at the top of the tower, and the steam is used to preheat the raw materials. The steam after preheating the raw materials enters the pressurized rectification tower 6. After rectification, the ethanol content of the tower reactor is ≤0.1 wt.% waste water, ethanol content 87wt.% positive pressure stream steam is obtained at the top of the tower, the positive pressure ethanol stream is divided into two streams, and the mass ratio of the two streams ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com