Ethyl alcohol production method and device

A production method and technology for a production device are applied in the field of ethanol production methods and devices, and can solve the problems of complex process, pollution and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

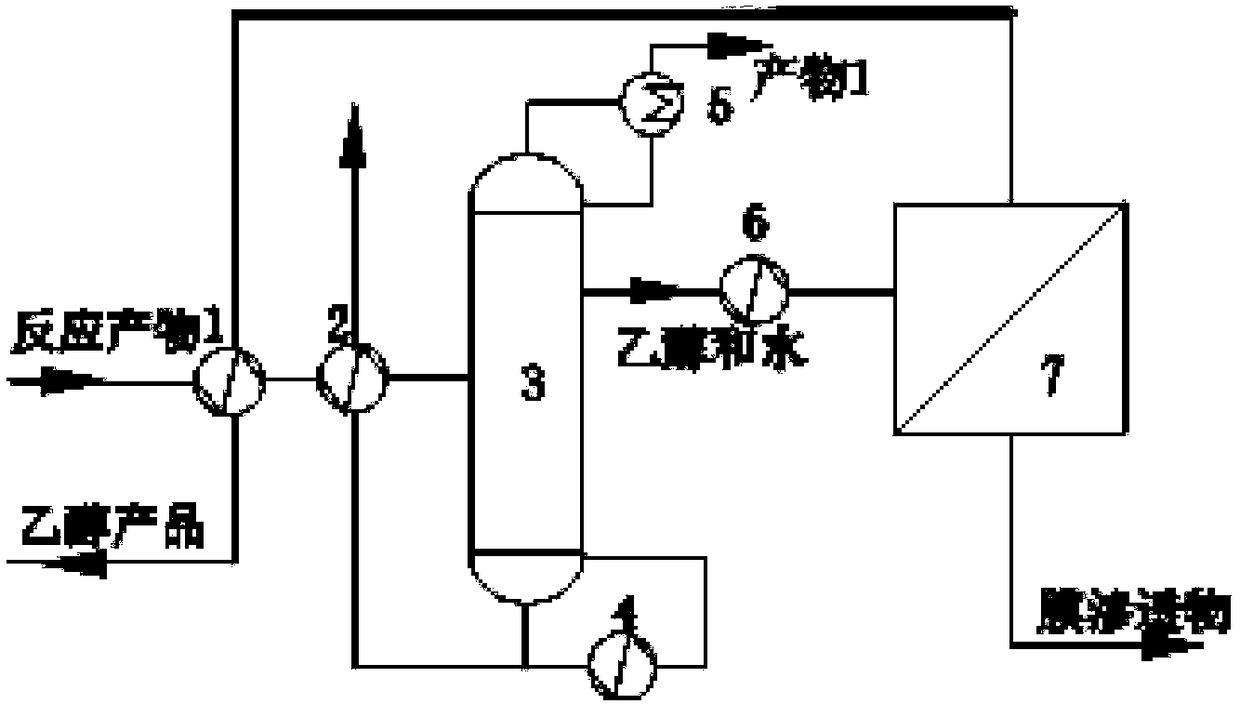

[0030] Such as figure 1 Shown, taking syngas (containing 65wt%H 2 , 30wt% CO) directly synthesize ethanol under the Cu-Co catalyst system, and the reaction product is separated by non-condensable gas to obtain steam containing 62wt% ethanol, 20wt% methanol, and 13wt% water, which is sent to the rectification tower for rectification , the pressure inside the rectification tower is 300kPa, the temperature at the bottom of the tower is 86°C, and the temperature at the top of the tower is 74°C. Methanol is extracted from the top of the tower, and ethanol (water content 8wt%) is extracted from the side line. After heat exchange and superheating, the material extracted from the side line , into the steam permeable membrane for dehydration, the steam permeable membrane is made of NaA molecular sieve membrane, the temperature of the feed liquid side is 114°C, the absolute pressure of the feed liquid side is 120kPa, the absolute pressure of the permeation side is 1000Pa, and the averag...

Embodiment 2

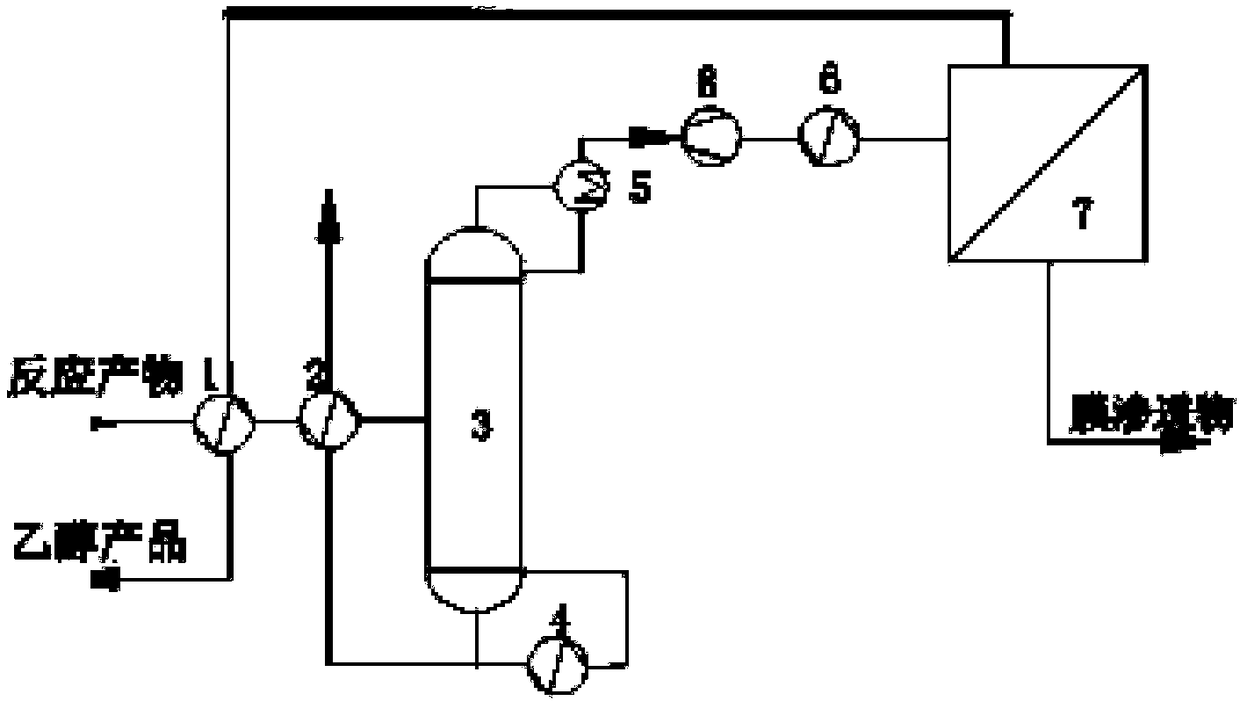

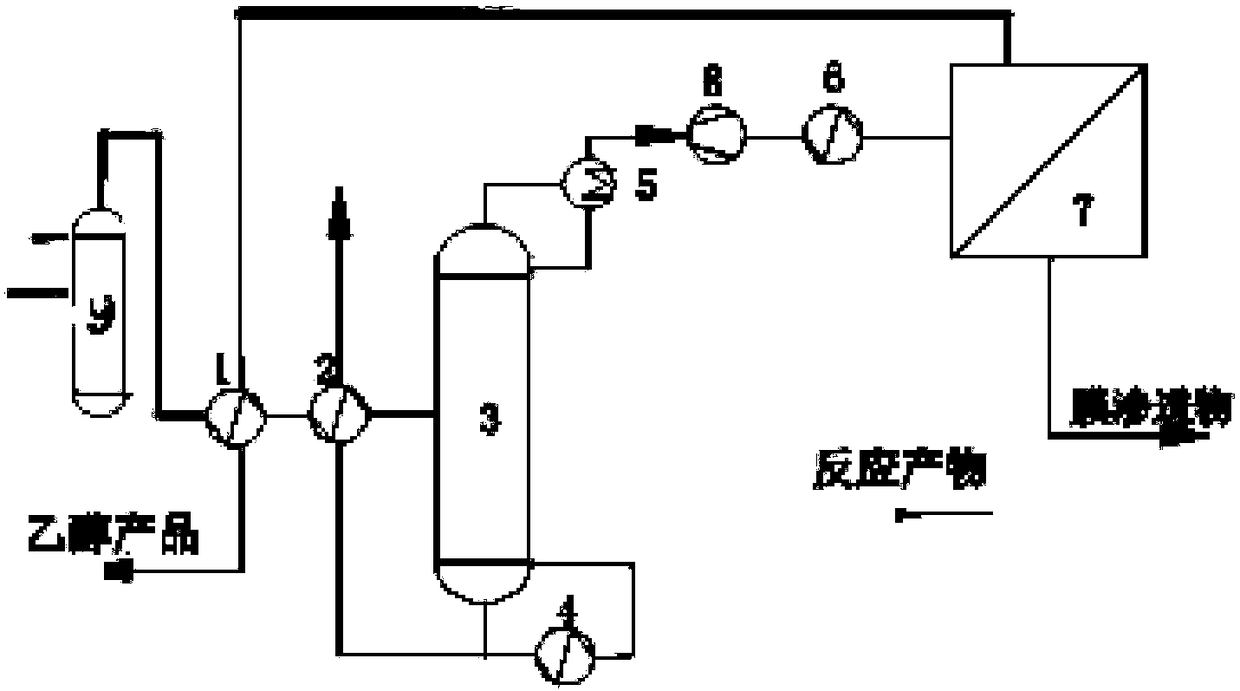

[0032] Such as figure 2 Shown, taking syngas (containing 65wt%H 2 , 30wt%CO) as a carbon source, using the fermentation method to produce ethanol (CN105755058A), the fermentation liquid is filtered to remove bacteria, and then sent to a rectification tower for rectification. The pressure inside the rectification tower is 300kPa, and the temperature at the bottom of the tower is 88 ℃, the temperature at the top of the tower is 78°C, ethanol (water content 16wt%) is extracted from the top of the tower, and the material extracted from the side line is heat exchanged and overheated, and then sent to the steam permeable membrane for dehydration. The steam permeable membrane uses NaA molecular sieve Membrane, feed liquid side temperature 110°C, feed liquid side absolute pressure 150kPa, permeation side absolute pressure 1500Pa, steam permeation membrane average water flux 0.98kg / m 2 h, the permeate side obtains an ethanol product with a water content of 0.8wt%.

Embodiment 3

[0034] Such as figure 2 Shown, taking syngas (containing 65wt%H 2 , 30wt%CO) to generate dimethyl ether (CH 3 OCH 3 ), carbonylation of dimethyl ether to generate methyl acetate, methyl acetate is hydrogenated under the action of a catalyst to produce methanol and ethanol (CN104710282A), and the product containing 54wt% methanol, 34wt% ethanol and 9wt% methyl acetate is sent to the refining Carry out rectification in the distillation tower, the pressure in the rectification tower is 350kPa, the temperature at the bottom of the tower is 88°C, and the temperature at the top of the tower is 76°C. Methanol is extracted from the top of the tower, and ethanol (water content 1.2wt%) is extracted from the side line. After heat exchange and overheating, the material is sent to the steam permeable membrane for dehydration. The steam permeable membrane is made of NaA molecular sieve membrane. Average water flux 0.93kg / m 2 h, the permeate side obtains an ethanol product with a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com