Honeycomb fired body, honeycomb filter, and method for producing honeycomb fired body

a technology of honeycomb and filter, which is applied in the direction of ceramic extrusion dies, machines/engines, chemical/physical processes, etc., can solve the problems of difficult to ensure the strength of the honeycomb fired body, damage to the environment and human body, etc., and achieve the effect of discharging ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1-1

(1) Production of Honeycomb Fired Body

(1-1) Ceramic Raw Material Preparing Step

[0299]A mixture was obtained by mixing 52.8% by weight of silicon carbide coarse powder having an average particle size of 22 μm, 22.6% by weight of silicon carbide fine powder having an average particle size of 0.5 μm. To the mixture were added 4.6% by weight of an organic binder (methylcellulose), 0.8% by weight of a lubricant (UNILUB available from NOF Corporation), 1.3% by weight of glycerin, 1.9% by weight of a pore-forming agent (acrylic resin), 2.8% by weight of oleic acid, and 13.2% by weight of water. Thus, a ceramic raw material was prepared.

(1-2) Extruding Step

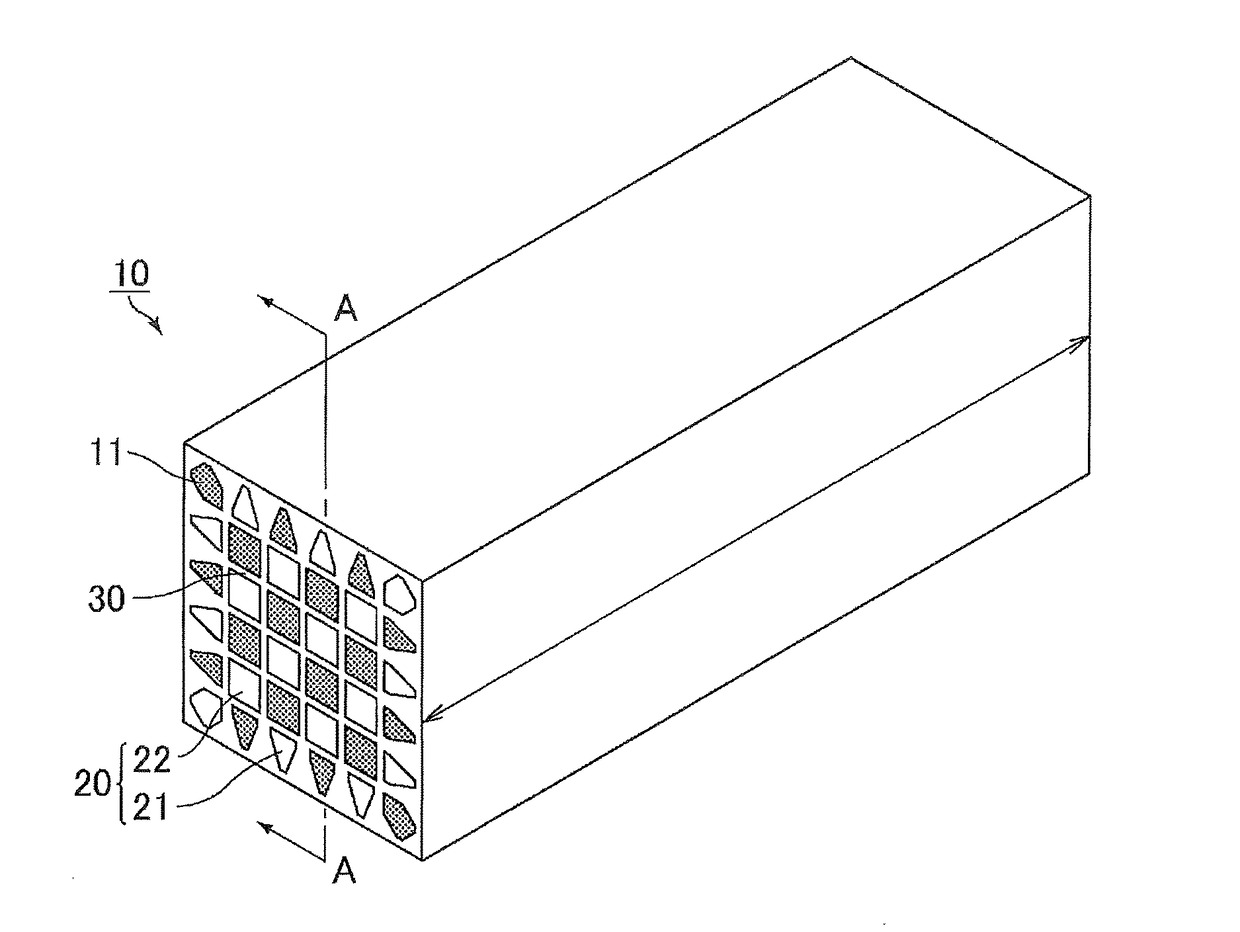

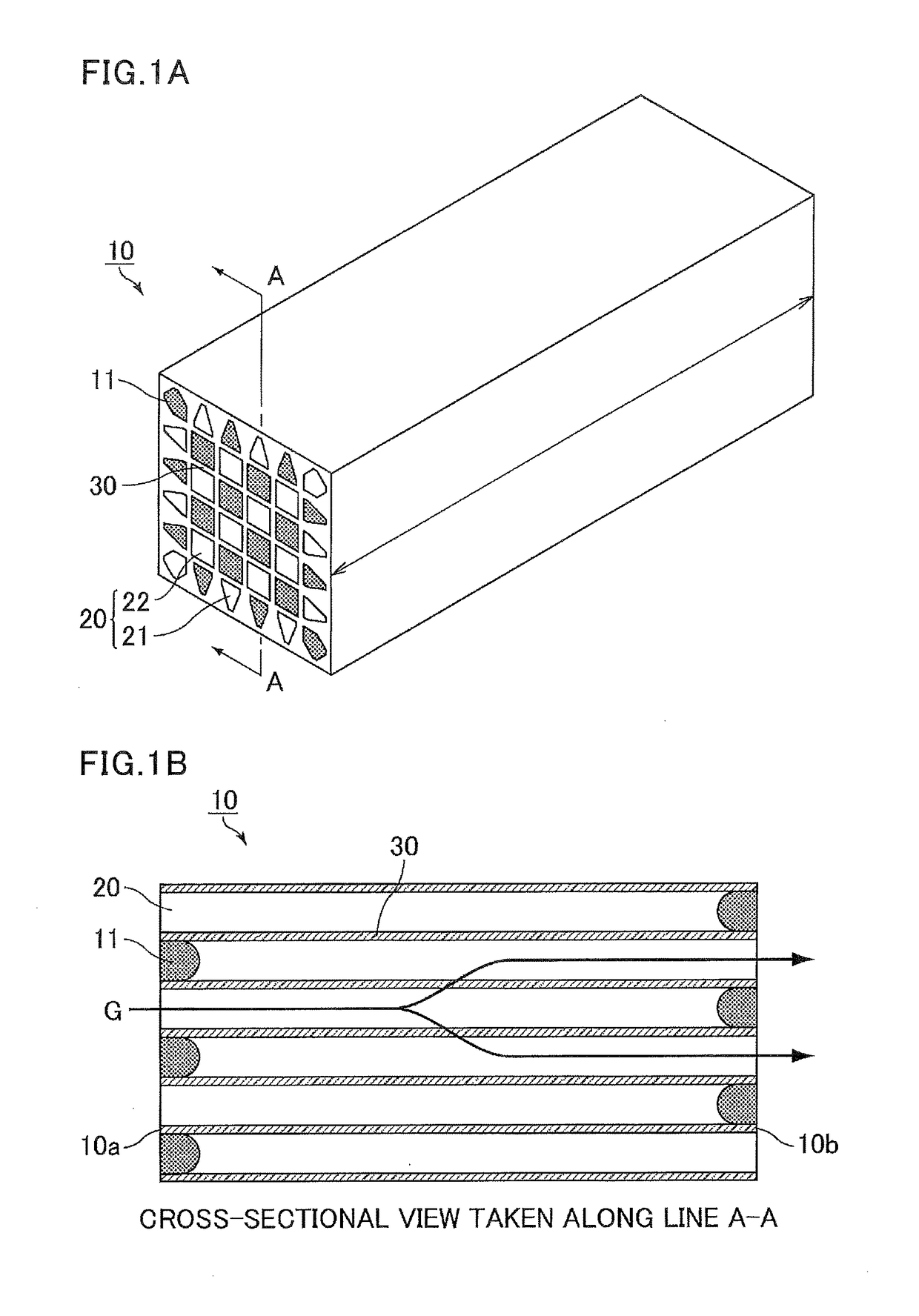

[0300]Next, the ceramic raw material prepared in the ceramic raw material preparing step was extruded into a honeycomb molded body as a precursor of the honeycomb fired body 10.

[0301]In the extruding step, an extrusion die having the following shape was used.

[0302]The material was cemented carbide obtained by sintering a mixture of tungst...

example 1-5

[0318]A honeycomb fired body according to Example 1-5 was produced in the same manner as in Example 1-1, except that in the extruding step (1-2), the raw material flow suppression section was provided on the inner wall surface of the outermost peripheral slit and the peripheral slits of the extrusion die. The surface roughness Ra of the provided raw material flow suppression section was 0.410 μm.

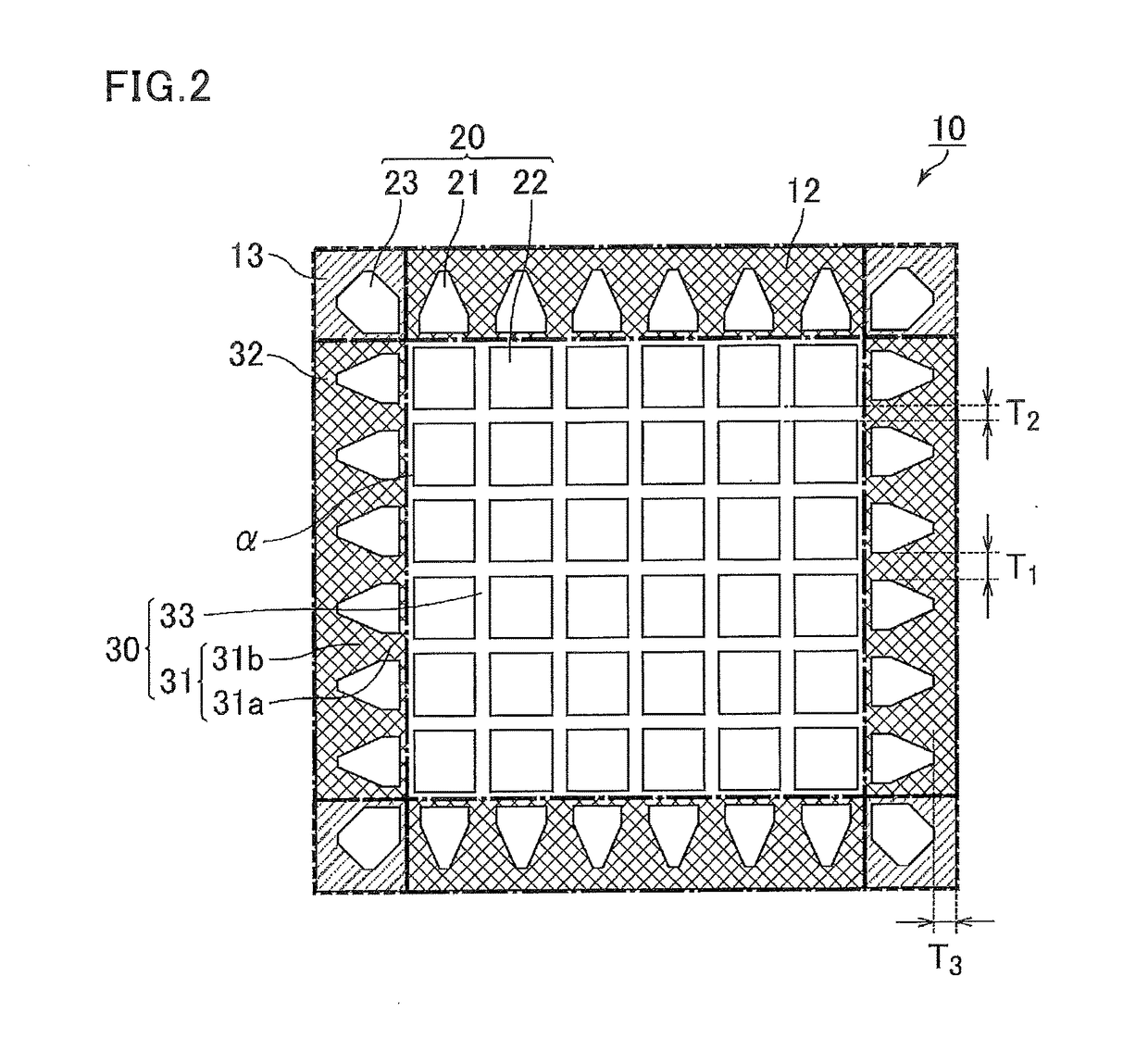

[0319]Table 1 shows the minimum thickness T1 of the inter-peripheral-cell cell partition walls and the percentage of the cross-sectional area relative to each peripheral cell to the cross-sectional area of each inner cell of the produced honeycomb fired body according to Example 1-5.

TABLE 1Cross-sectionalMinimumarea of peripheralthickness T1 (mm) ofcell / Cross-sec-Yieldinter-peripheral-celltional area ofratecell partition wallsinner cell (%)(%)Example1-10.30066.5921-20.25069.5881-30.35063.5961-40.40060.5981-50.30066.596Comparative1-10.20072.575Example

(Calculation of Yield Rate)

[0320]Fifty hon...

example 2

[0323]A honeycomb filter according to Example 2 was produced by the following method.

(1) Preparation of Honeycomb Fired Body

[0324]The honeycomb fired body according to Example 1-1 was prepared as a honeycomb fired body for a honeycomb filter.

(2) Production of Honeycomb Filter

(2-1) Adhesive Paste Preparing Step

[0325]A heat resistant adhesive paste was prepared by mixing 30% by weight of alumina fibers having an average fiber length of 20 μm, 21% by weight of silicon carbide particles having an average particle size of 0.6 μm, 15% by weight of silica sol, 5.6% by weight of carboxymethyl cellulose, and 28.4% by weight of water.

(2-2) Assembling Step

[0326]The adhesive paste was applied to the lateral sides of each prepared honeycomb fired body to assemble the honeycomb fired bodies.

[0327]Subsequently, the assembled honeycomb fired bodies were heated at 120° C., whereby the adhesive paste was solidified by heating into an adhesive layer, and an aggregate of the honeycomb fired bodies was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| slit width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com