Composite stainless steel spherical digester

A technology of stainless steel and stainless steel layer, which is applied in the direction of digester, textile and papermaking, and fiber raw material processing, etc., which can solve the problems of potential safety hazards, reduced service life of steaming balls, corrosion of steaming ball walls, etc., and achieves wide application range and improved use Environment and range of use, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

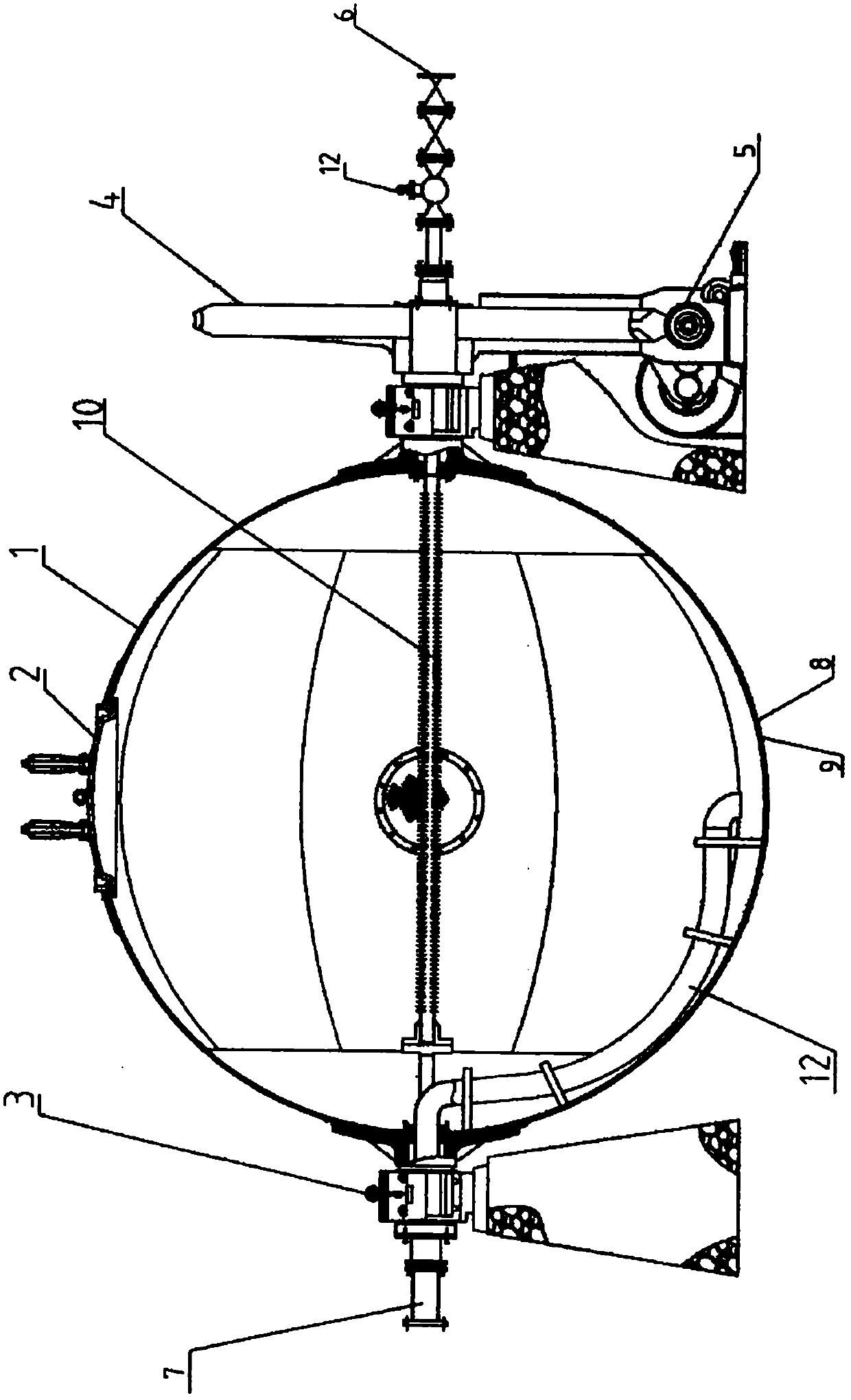

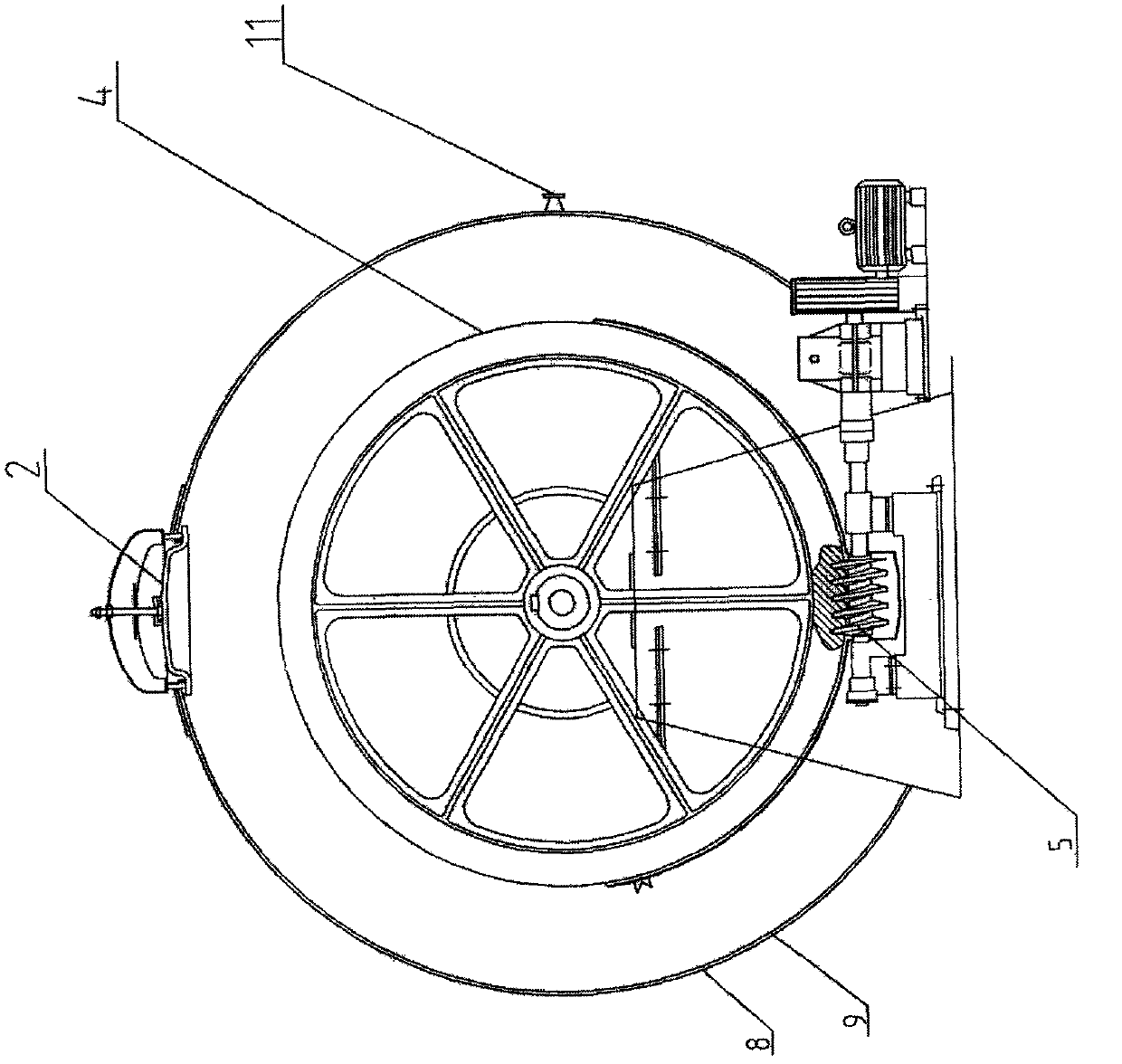

[0010] see figure 1 and figure 2 , The stainless steel composite steaming ball includes a bracket, a steaming ball, a transmission part, an air inlet and an air outlet, an air inlet pipe and a discharge pipe. Among them, the spherical shell is composed of an outer carbon steel layer and an inner stainless steel layer. A heat insulating layer is also arranged between the inner and outer layers of the spherical shell.

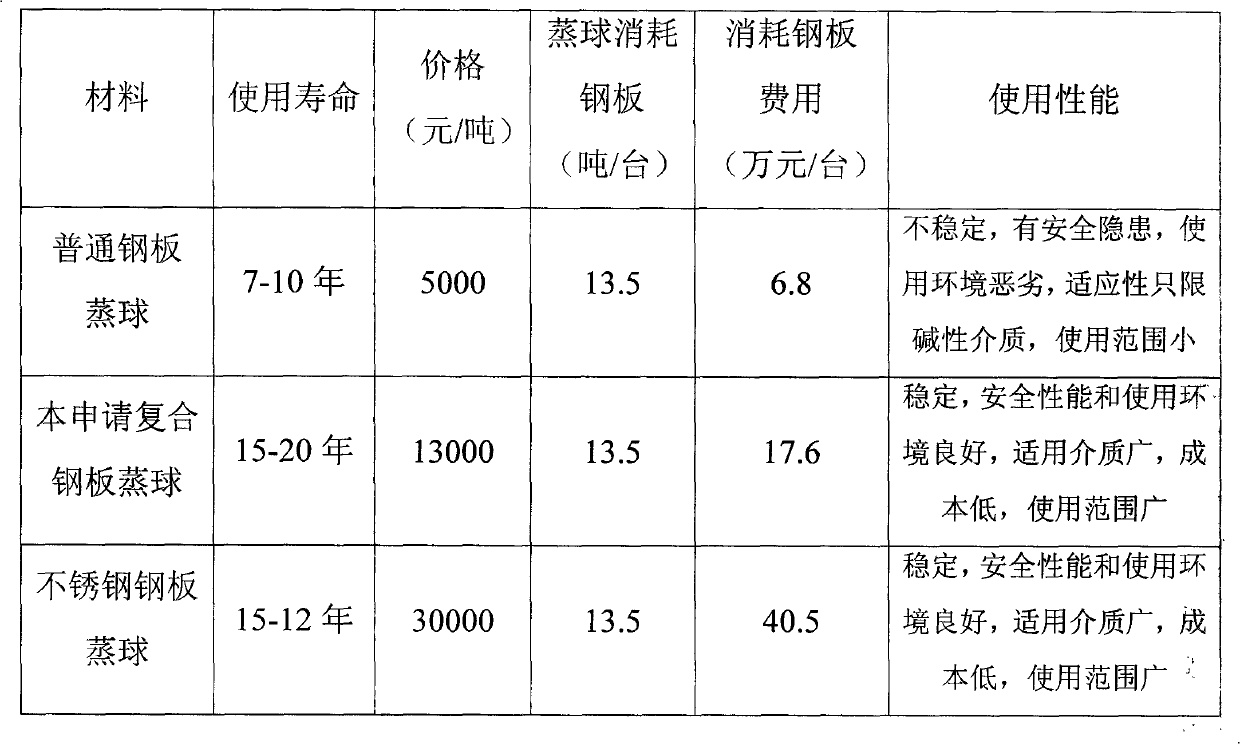

[0011] Economic Benefit Analysis:

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com