Use of Methanol in the Production of Hydrogen and Fuel, Processes and Plants for the Production of Hydrogen and Fuel

a technology of methanol and hydrogen, which is applied in the direction of hydrogen/synthetic gas production, hydrogen/oxo compound production, specific gas purification/separation, etc. it can solve the problems of contaminated biomethanol with said sulphur compounds, a large number of organic sulphur compounds, and a large number of different organic sulphur compounds, so as to remove malodorous sulphur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

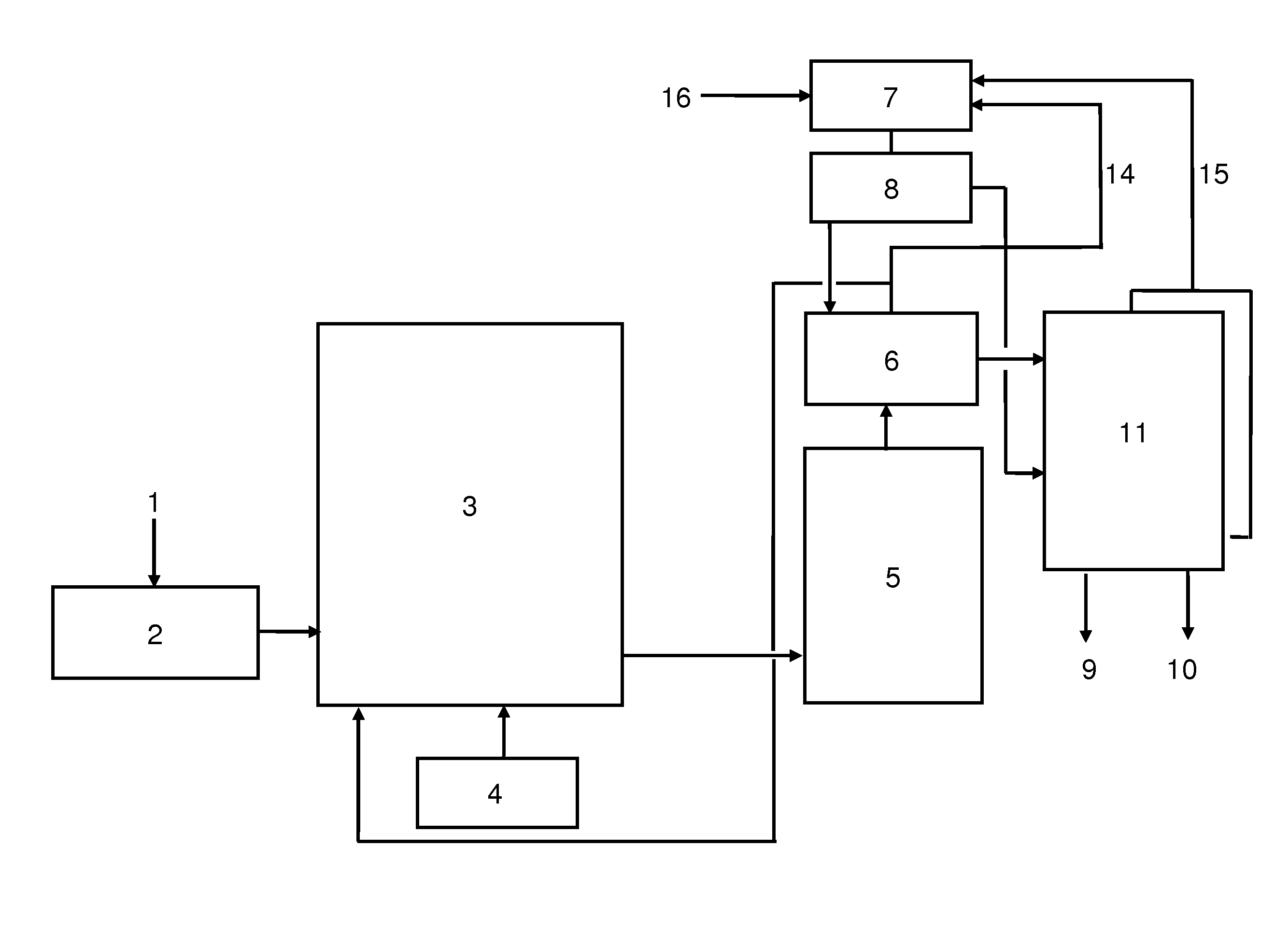

[0094]FIG. 1 shows a schematic flow diagram of a biomass-to-liquid (BTL) process located in close connection to and integrated with a Kraft pulp and paper mill (not shown). The BTL process produces biofuel using biohydrogen derived from pulp biomethanol.

[0095]The biomass-to-liquid process comprises feeding of biomass 1 to a feed stock pretreatment unit 2, where after the feed stock is led to a gasification and gas conditioning unit 3 for synthesis gas production. The gasification and gas conditioning unit 3 includes i.a. scrubbing of the gas and a water gas shift (WGS) unit. The unit 3 is connected to an air separation unit (ASU) 4 for production of oxygen. Before the Fischer-Tropsch (FT) synthesis unit 6, the gas is treated in a gas processing and clean-up unit 5.

[0096]Biohydrogen is produced in an autothermal reforming (ATR) unit 7 from purified biomethanol 16 recovered from the Kraft pulp mill. Also tail gases 14 and off-gases 15 from the BTL process are fed to the ATR unit 7 for...

example 2

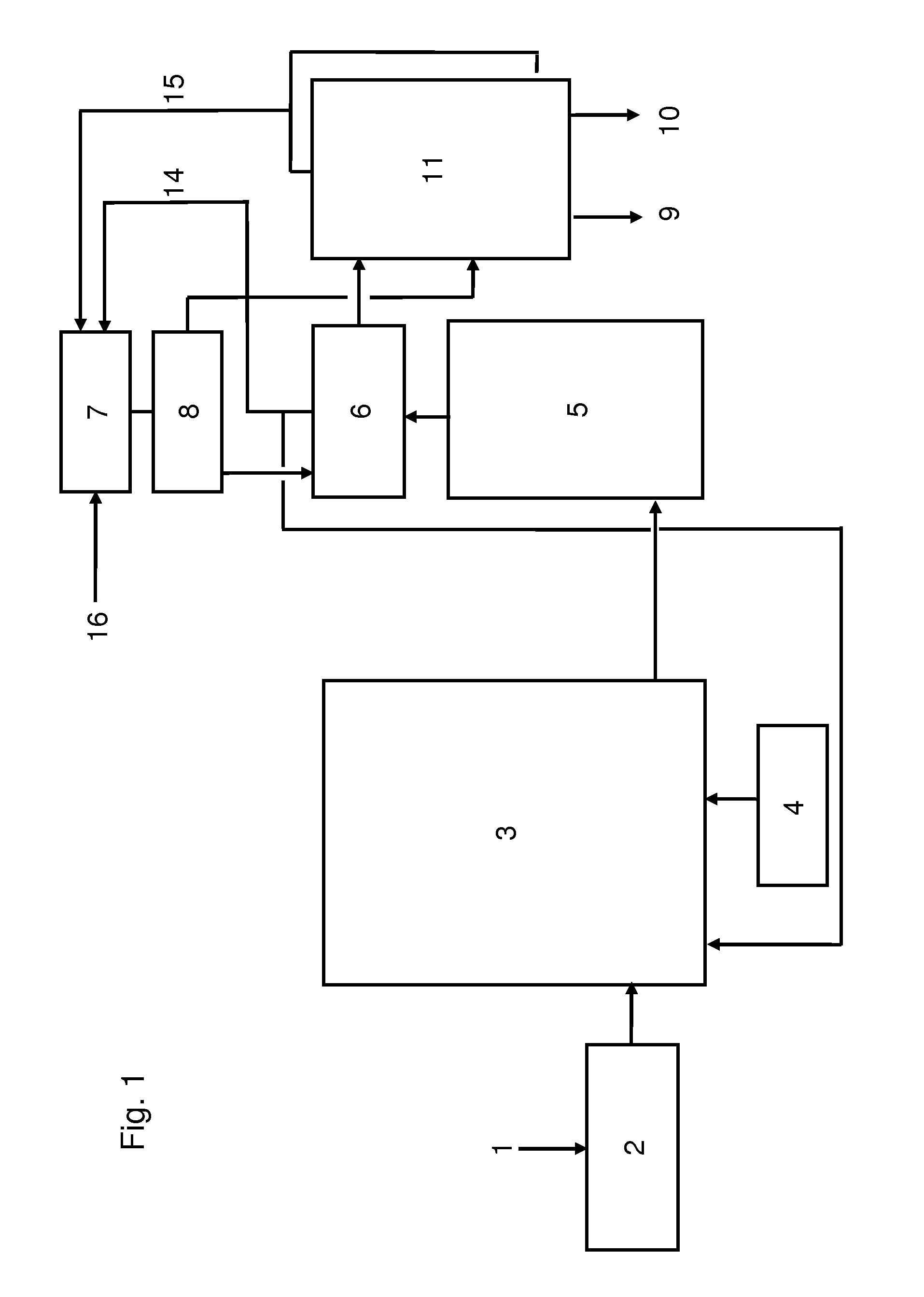

[0098]Biohydrogen is produced from crude biomethanol recovered from a Kraft pulping process in accordance with the diagram shown in FIG. 2.

[0099]Crude biomethanol produced in the Kraft pulping process is distilled and / or stripped in recovery unit 12 and is introduced into a methanol purification unit 13 that is capable of removing sulphur compounds. In the shown embodiment, the purification unit 13 comprises two adsorbers, each containing an adsorbent bed. The adsorbers are used alternately, one being in use, while the other is regenerated. Further purification means such as scrubbers, washers, absorbers, and catalytic reactors may be added at need.

[0100]The purified biomethanol is directed to an autothermal reforming unit (ATR) 7, to which also air is introduced. The ATR unit 7 produces a gas mixture containing biohydrogen, carbon dioxide, nitrogen, ammonia and hydrogen sulphide. The gas also contains minor amounts of higher molecular weight sulphur compounds of a malodorous nature...

example 3

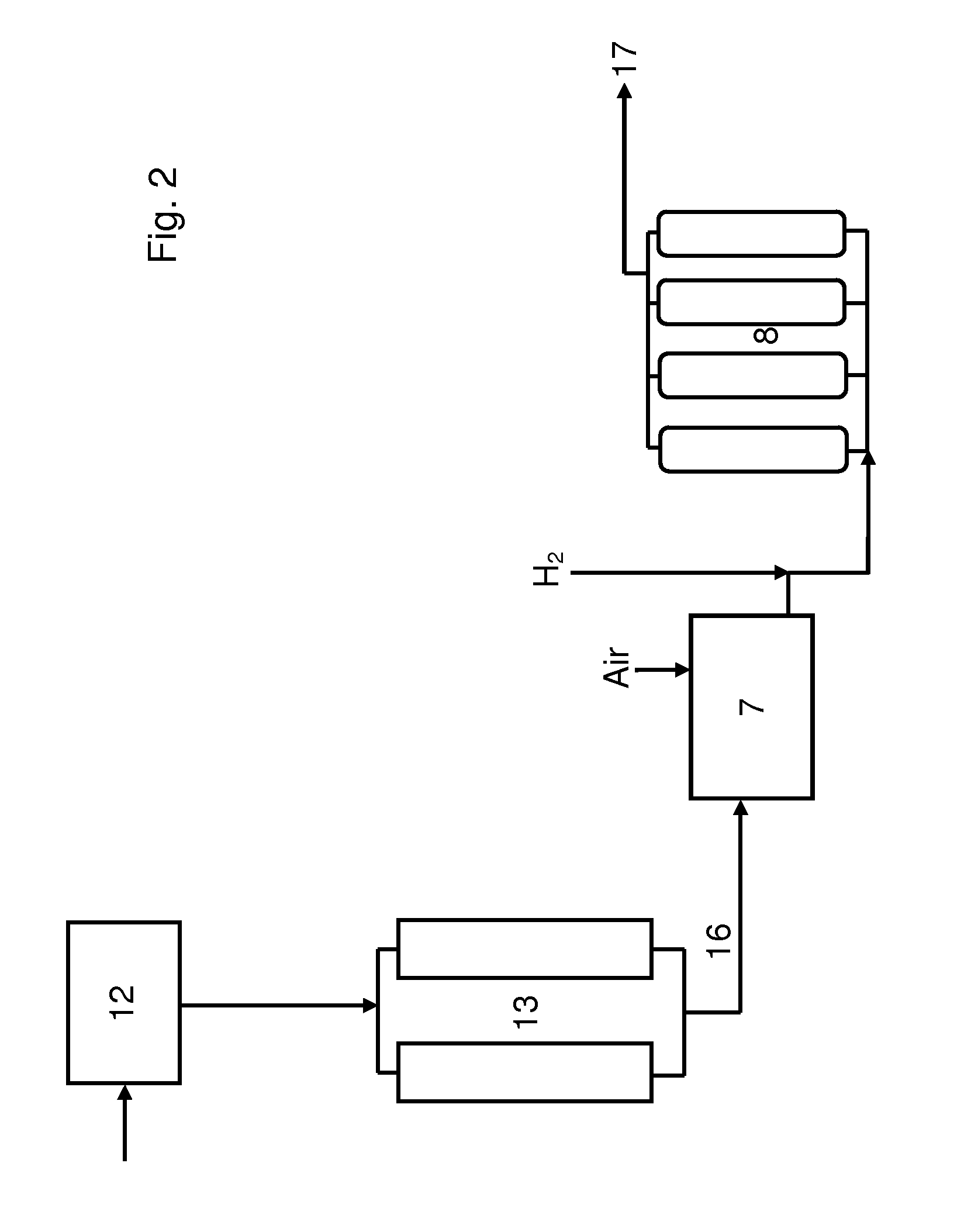

[0101]FIG. 3 is a schematic flow diagram of the use of biohydrogen produced in a Kraft pulp mill 19 integrated with a biofuel production plant 20.

[0102]Wood for the pulp mill 19 is procured and handled in wood logistics facility 18 for use as raw material in the production of pulp. Bark recovered in the wood handling of the facility 18 is incinerated in the boiler (not shown) of the pulp mill 19 for energy production. Energy wood (mainly forest residue) 1 from the common wood logistics facility 18 is fed to the biomass-to-liquid (BTL) plant 20.

[0103]In this example about 2.1 TWh / a (terawatt hours / annum) or about 1 Mio m3 / a (millions of cubic meter / annum) of forest residue is fed to the BTL plant 20. The BTL process produces 65,000-88,000 t / a (metric ton / annum) of middle distillate and 20,000-27,000 t / a of naphtha. The Kraft pulp process produces about 600,000-700,000 t / a pulp.

[0104]The Kraft pulp mill 19 produces black liquor from which about 20,000 t / a crude biomethanol is recovere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com