Pretreatment method assists in realizing wheat straw high-efficiency enzymatic hydrolysis conversion

A technology of enzymatic hydrolysis and pretreatment, applied in the direction of fermentation, etc., can solve problems such as patent publications that have not been found, and achieve the effects of saving economic costs, saving energy, and improving high-efficiency conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

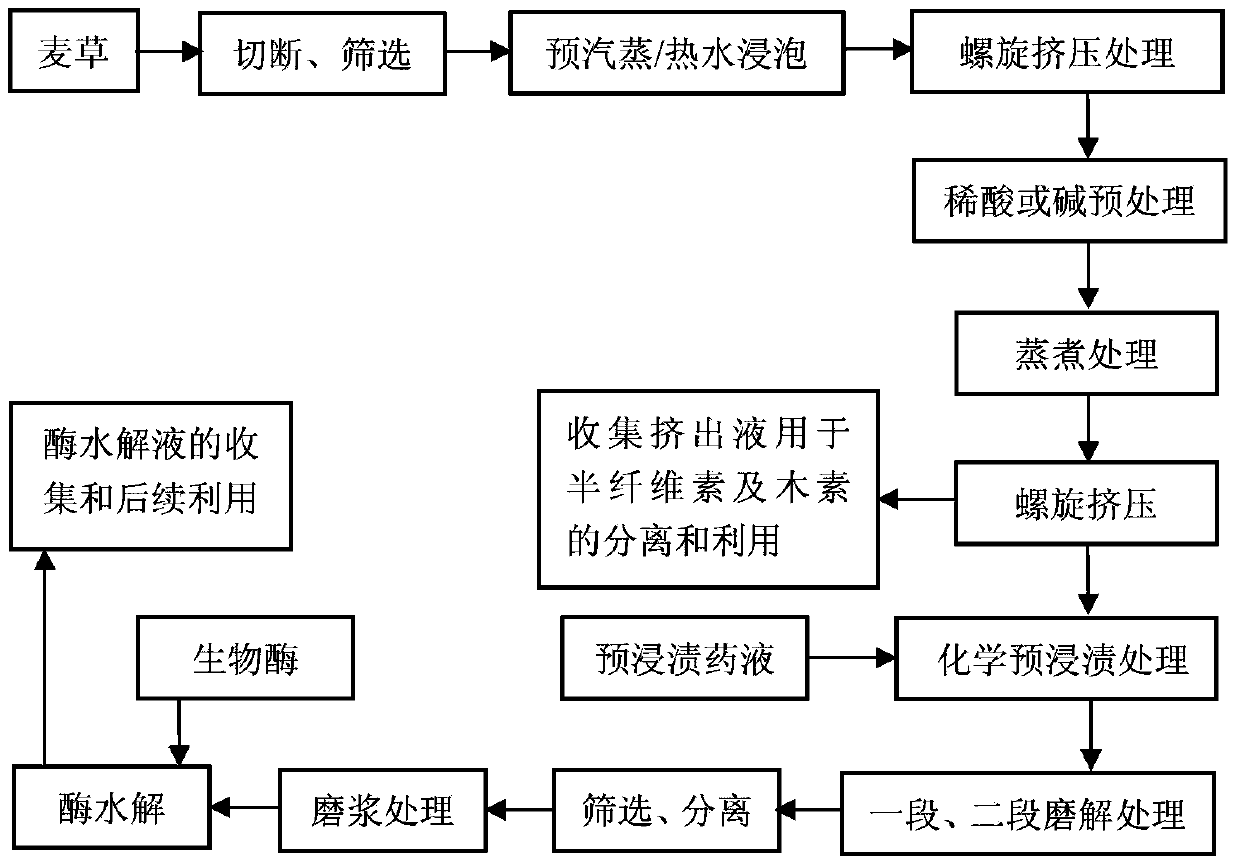

Image

Examples

Embodiment 1

[0032] A pretreatment method capable of realizing efficient enzymatic hydrolysis conversion of wheat straw, the steps are as follows:

[0033] ⑴ First, cut and screen the raw materials of wheat straw, select about 5cm of wheat straw, and wash with water for 3-4 times;

[0034] (2) Soak the selected wheat straw in hot water at 95°C for 20 minutes, and then place the wheat straw soaked in hot water in a screw extruder for extrusion. The compression ratio of the screw extruder is 4 :1;

[0035] (3) Put the wheat straw processed by screw extrusion into the cooking tank, add 1.5% (w / w) (relative to the mass of dry wheat straw) H 2 SO 4(analytically pure, mass concentration is 98%), then add distilled water, the ratio of the mass of dry wheat straw to the total liquid volume after adding distilled water is 1:10, and cook at a temperature of 150°C. The heating time during the cooking process is controlled At 60 minutes, the holding time is 50 minutes, after a certain degree of dil...

Embodiment 2

[0045] A pretreatment method capable of realizing efficient enzymatic hydrolysis conversion of wheat straw, the steps are as follows:

[0046] ⑴ First, cut and screen the raw materials of wheat straw, select about 5cm of wheat straw, and wash with water for 3-4 times;

[0047] (2) Soak the selected wheat straw in hot water at 95°C for 20 minutes, and then place the wheat straw soaked in hot water in a screw extruder for extrusion. The compression ratio of the screw extruder is 4 :1;

[0048] (3) Put the wheat straw processed by screw extrusion into the cooking tank, add 10% (relative to the mass of dry wheat straw) NaOH, and then add distilled water, the ratio of the mass of dry wheat straw to the total liquid volume after adding distilled water is 1 : 10, carry out cooking, cooking temperature is 150 ℃, the heating time in the cooking process is controlled at 60 minutes, and the holding time is 50 minutes, through a certain degree of dilute sulfuric acid or alkali pretreatme...

Embodiment 3

[0058] A pretreatment method capable of realizing efficient enzymatic hydrolysis conversion of wheat straw, the steps are as follows:

[0059] ⑴ First, cut and screen the raw materials of wheat straw, select about 5cm of wheat straw, and wash with water for 3-4 times;

[0060] (2) Soak the selected wheat straw in hot water at 95°C for 20 minutes, and then place the wheat straw soaked in hot water in a screw extruder for extrusion. The compression ratio of the screw extruder is 4 :1;

[0061] (3) Put the wheat straw processed by screw extrusion into the cooking tank, add 10% (relative to the mass of dry wheat straw) NaOH, and then add distilled water, the ratio of the mass of dry wheat straw to the total liquid volume after adding distilled water is 1 :10, carry out cooking, cooking temperature is 150 ℃, the heating time in the cooking process is controlled at 60 minutes, and the holding time is 50 minutes, through a certain degree of alkali pretreatment to extract part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com