Process and device for pulping by reversely extracting grass raw materials

A technology of countercurrent extraction and grasses, which is applied to pulping of cellulose raw materials, fiber raw materials treatment, pulping with organic solvents, etc., can solve the problems of conflicting main power factors, and achieve high profits, simple recovery technology, and low water consumption. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

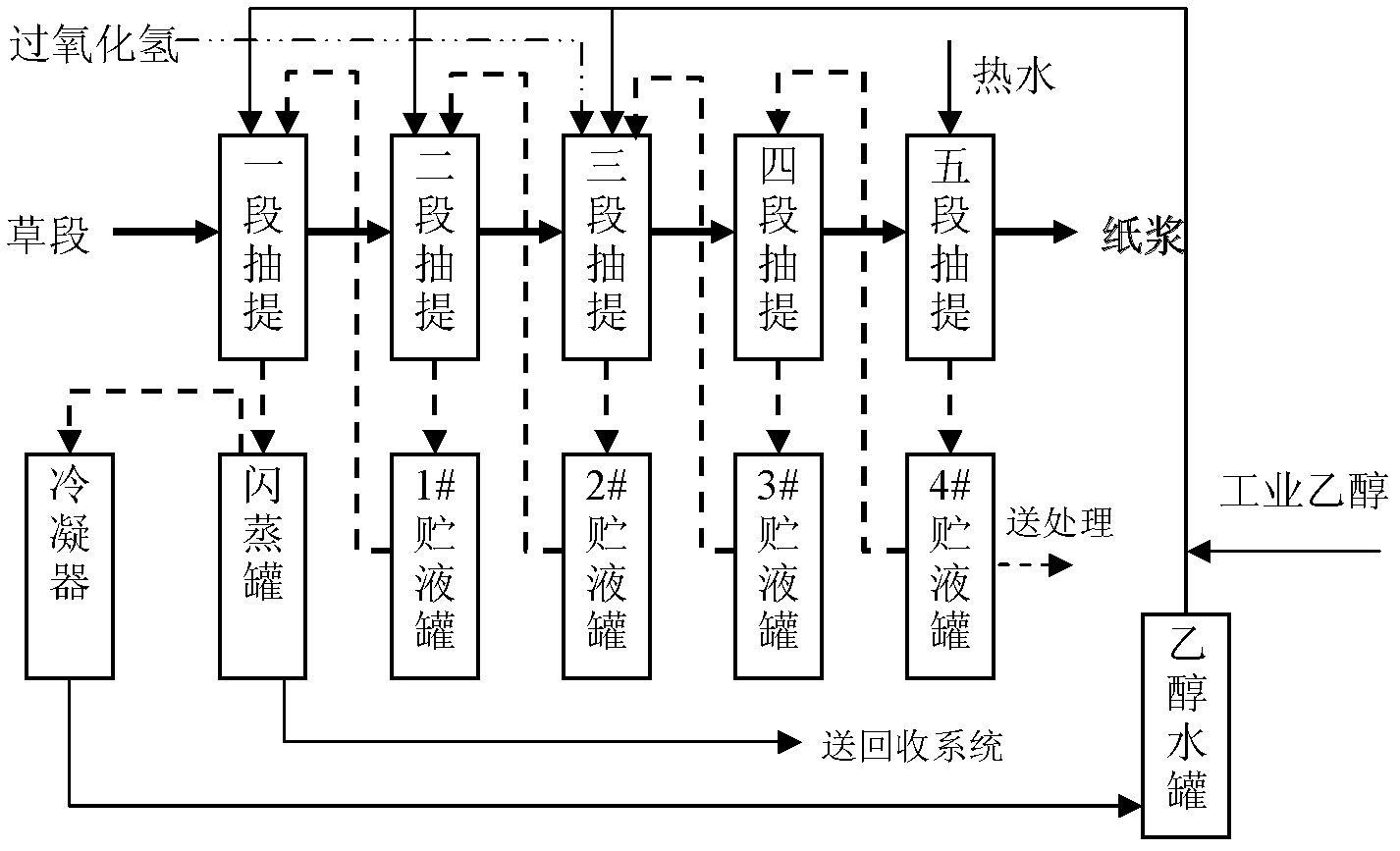

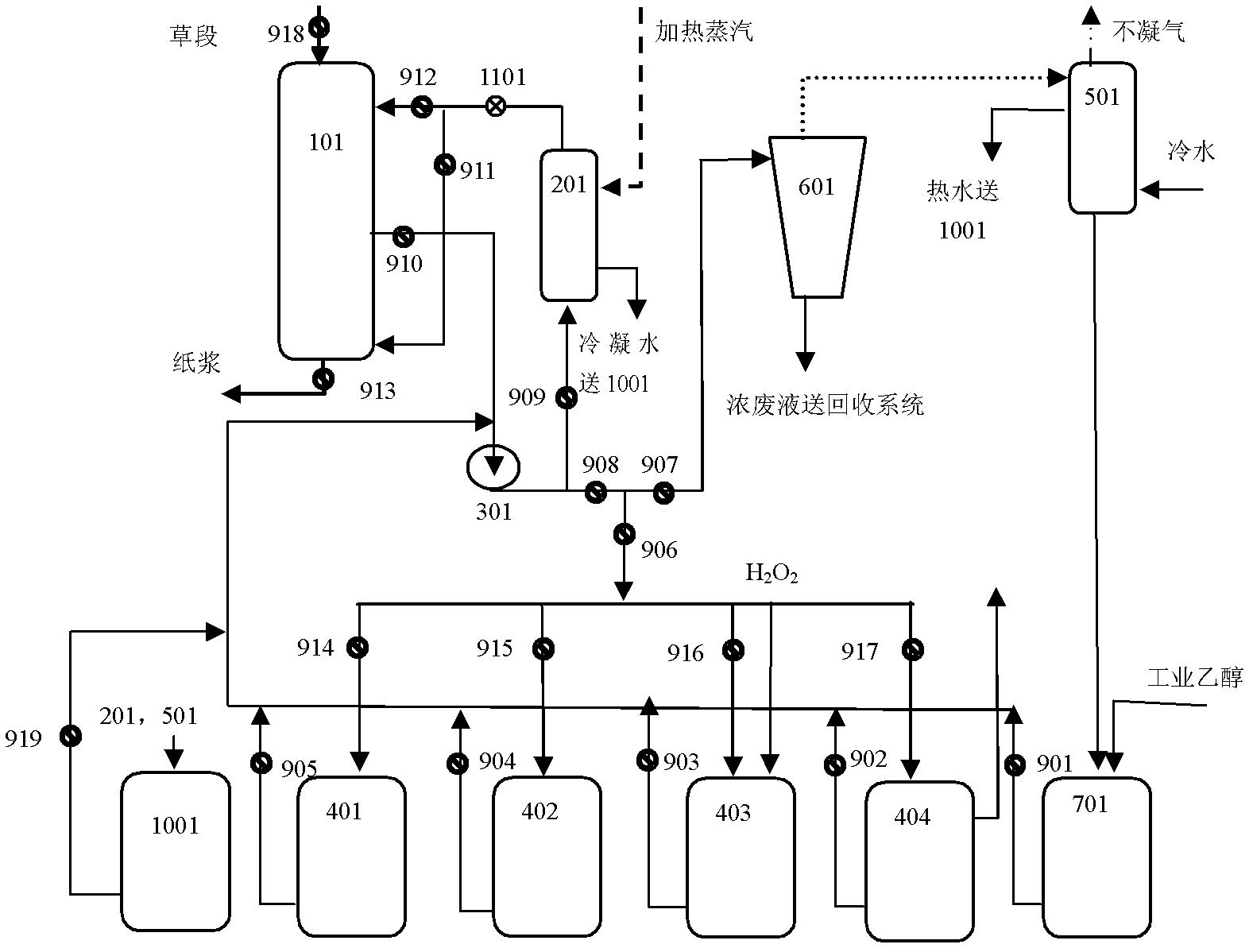

[0043]A countercurrent extraction and pulping method for grass raw materials, which uses ethanol-water-hydrogen peroxide five-stage countercurrent pulping for reed raw materials, and the process steps are as follows:

[0044] a. Cut the reed raw material into grass sections and put them into a pressure vessel, perform one-stage extraction according to the liquid ratio (g:mL) of 1:8, the extract used in the first-stage extraction is the second-stage extraction waste liquid, and recover ethanol by adding Control the volume concentration of ethanol to 50%, extracting temperature at 170°C, and extracting time for 150 minutes. After the first stage of extraction is completed, the extraction waste liquid is released into the flash tank to recover part of the ethanol, and the other waste liquid is sent to the recovery system. The slurry in the pressure vessel The material is subjected to two-stage extraction;

[0045] b. The second-stage extraction is carried out with the third-stage...

Embodiment 2

[0079] A method for countercurrent extraction and pulping of grass raw materials, using ethanol-water-hydrogen peroxide five-stage countercurrent pulping for wheat straw raw materials, the process steps are as follows: the process operation is the same as that of Example 1, and the process conditions are as follows:

[0080] One-stage extraction: temperature 175°C, time 150min, liquid ratio 1:7, ethanol concentration 55%;

[0081] Two-stage extraction: temperature 150°C, time 60min, liquid ratio 1:7, ethanol concentration 55%;

[0082] Three-stage extraction: temperature 130°C, time 60min, liquid ratio 1:7, ethanol concentration 55%, hydrogen peroxide dosage 1.0%;

[0083] Four-stage extraction: temperature 80°C, time 30min; liquid ratio 1:4;

[0084] Five-stage extraction: temperature 80°C, time 30min, liquid ratio 1:4.

[0085] The obtained pulp quality is listed in Table 2.

[0086] Table 2 Pulping effect of five-stage countercurrent extraction of wheat straw

[0087] ...

Embodiment 3

[0089] A method for countercurrent extraction and pulping of grass raw materials, using ethanol-water-hydrogen peroxide five-stage countercurrent pulping for wheat straw raw materials, the process steps are as follows: the process operation is the same as that of Example 1, and the process conditions are as follows:

[0090]One-stage extraction: temperature 165°C, time 180min, liquid ratio 1:8, ethanol concentration 50%;

[0091] Two-stage extraction: temperature 150°C, time 80min; liquid ratio 1:8, ethanol concentration 50%;

[0092] Three-stage extraction: temperature 130°C, time 60min, liquid ratio 1:8, ethanol concentration 50%, hydrogen peroxide dosage 1.5%;

[0093] Four-stage extraction: temperature 80°C, time 30min, liquid ratio 1:5.

[0094] Five-stage extraction: temperature 80°C, time 30min, liquid ratio 1:5.

[0095] The obtained pulp quality is listed in Table 3.

[0096] Table 3 Pulping effect of reed five-stage countercurrent extraction

[0097] Fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com