Method for separating bark from stalk and bark and stem separator

A technology for separating equipment and cotton rods, which is applied in the field of rod separation and leather, to achieve the effect of good separation effect, high separation efficiency and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

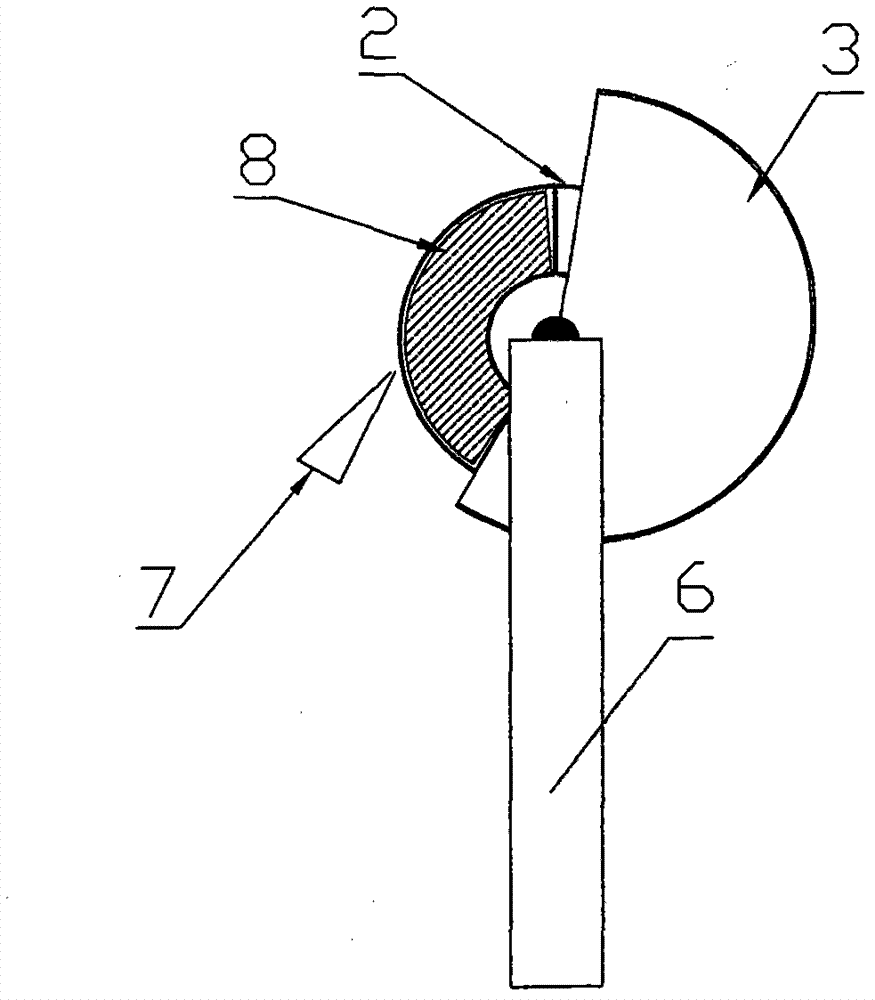

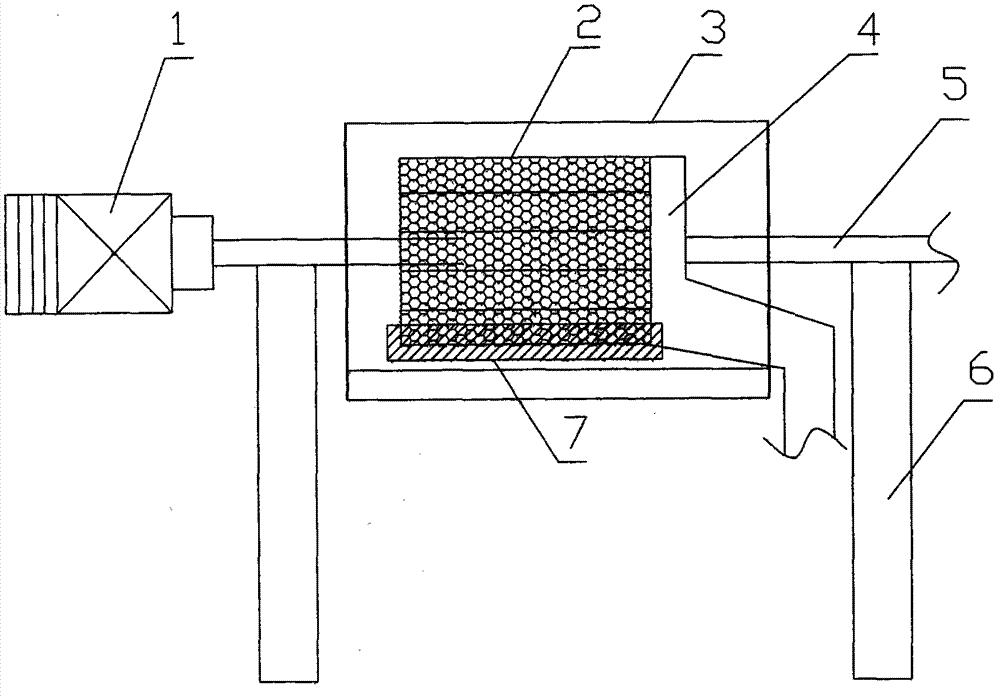

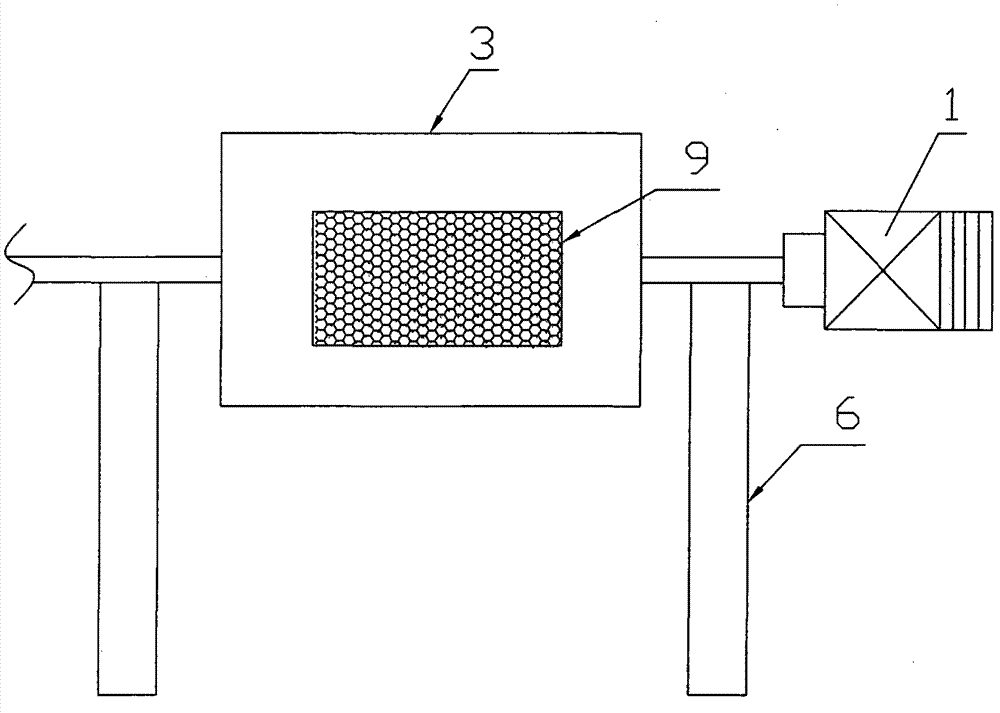

[0030] As shown in the drawings, the leather rod separator shown in this embodiment mainly includes a transmission mechanism 1, a drum 2, an outer cover 3, and a vacuum cover 4, wherein the drum 2 is a cylindrical structure, and is located on the outer cover 3. Inside, the rotating drum 2 is connected with the transmission mechanism 1 through the rotating shaft 5 , the rotating shaft 5 is supported by the support frame 6 , the outer cover 3 is an open structure at the front, and a feeding port 9 is provided at the rear. There are several sieve holes distributed on the circumferential surface of the drum 2, and the sieve holes are in an inverted cone structure, wherein, the end of the large hole faces the inside of the drum 2, and the end of the small hole faces the outside of the drum 2, and the diameter of the small hole can be 3-10 mm, and the diameter of the large hole The hole diameter may be 6-15 mm. The cavity of the drum 2 is provided with a number of partitions 10 radi...

Embodiment 2

[0034] A method for separating cotton stalks, mulberry trees, mulberry trees, and other pulverized materials from leather and rods, which adopts leather and rod separation equipment for separation. The raw materials are sent to the skin rod separation equipment, and the relatively broken rod materials are sucked into the cavity of the drum by vacuum suction and discharged, and the longer skin fibers are adsorbed on the surface of the drum and are unloaded with the rotation of the drum.

[0035] As shown in the drawings, the skin-rod separation equipment can adopt the following structure: the drum cavity of the skin-rod separation equipment is provided with a number of partitions 10 radially distributed, and the partitions 10 divide the drum The inner cavity is divided into several relatively independent small chambers 11 along the axial direction. One end of the drum is sealed, and the other end is provided with a shield. The vacuum cover 4 connected to the end of the drum and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com