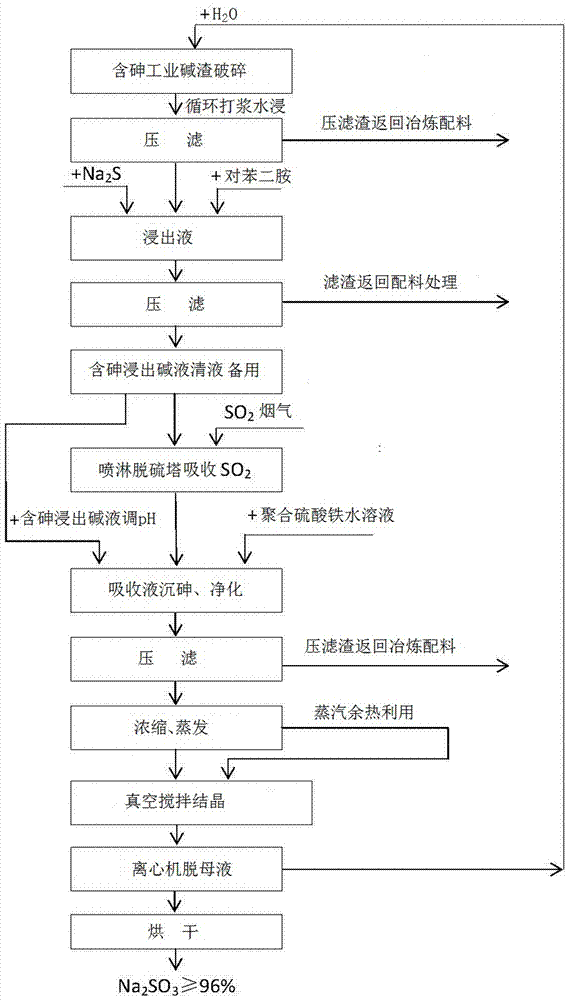

Technique for producing sodium sulfite products by absorption of SO2 flue gas through arsenic-containing industrial alkali residue water alkali liquor and arsenic removal purification

A technology of lye absorption and sodium sulfite, which is applied in the production of sodium sulfite products, flue gas desulfurization and inorganic chemical industry. It can solve the problems of no practical value and insufficient work, so as to optimize the technical process and parameter selection, increase the product content, and achieve huge The effect of environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Smelting blast furnace hearth area 5.6m 2 , flue gas displacement 50000m 3 / h, SO in flue gas 2 Concentration 5000mg / m 3 , the diameter of the spray desulfurization tower is 2.5m, the height of the single-stage tower is 10m, and the spraying arrangement is 4 layers. 2 : 5000×2.7%=135mg / m 3 , less than 200mg / m2 allowed by the national second-class factory area 3 standard. The arsenic-containing industrial alkali slag crushing and water immersion circulation beating system uses a B250×L400 hammer crusher to spray water to eliminate dust for coarse crushing, and combines a φ1.8×L3.6m ball mill and a spiral classifier to combine 15m 3 × 2 stirring tanks to form a circulating beating and leaching system. When the total specific gravity of suspended slag in the beating water reaches 1.35, pump out the filter press (two sets of 60m 2 Alternate pressure filtration by box filter press) to obtain a leach solution with a specific gravity of about 1.12, which contains about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com