Chemical-electric poly-generation method and equipment

A technology for polygeneration and chemical products, applied in chemical instruments and methods, preparation of organic compounds, mechanical equipment, etc., can solve the problems of low catalyst efficiency, large slurry bed equipment, and large reaction heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

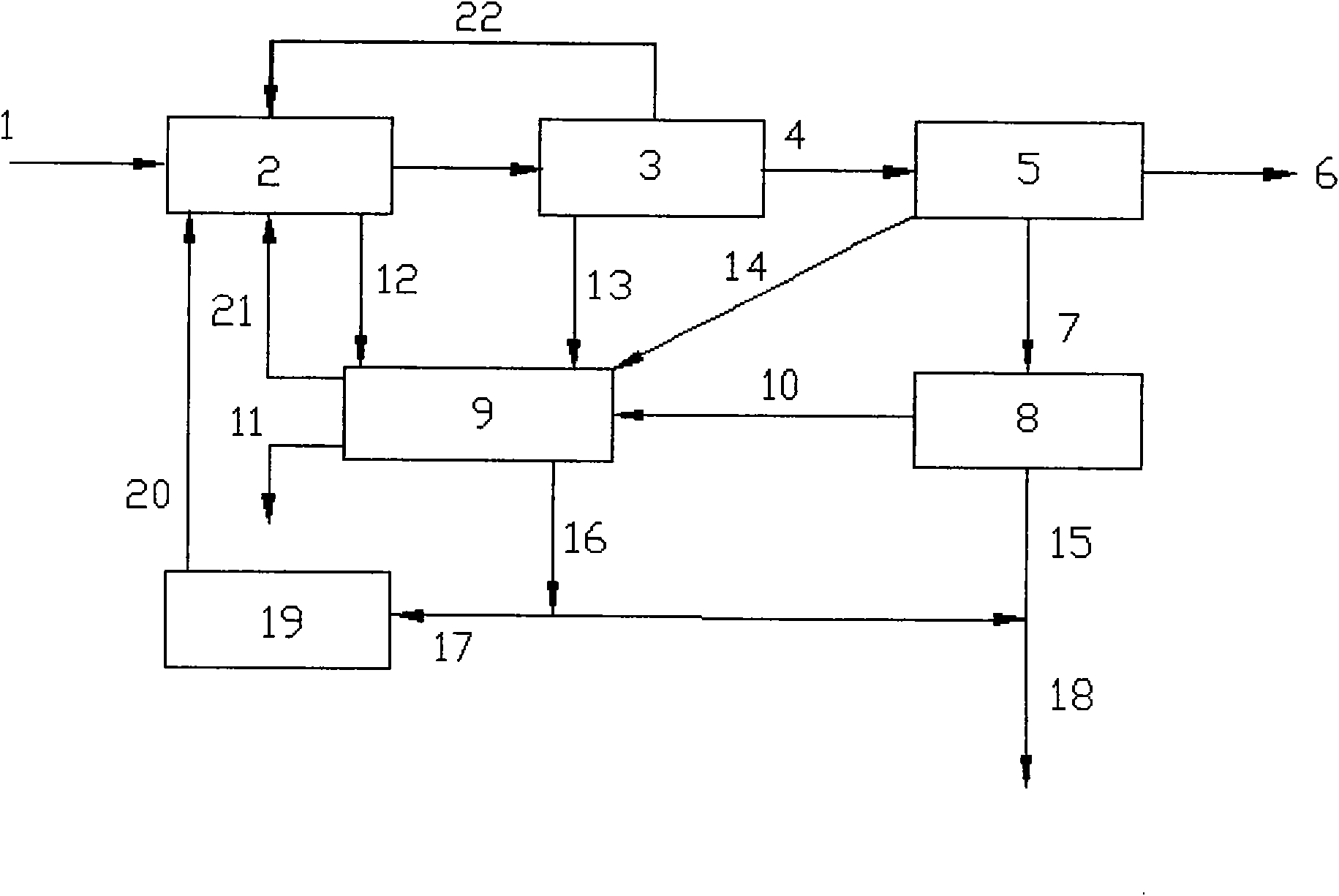

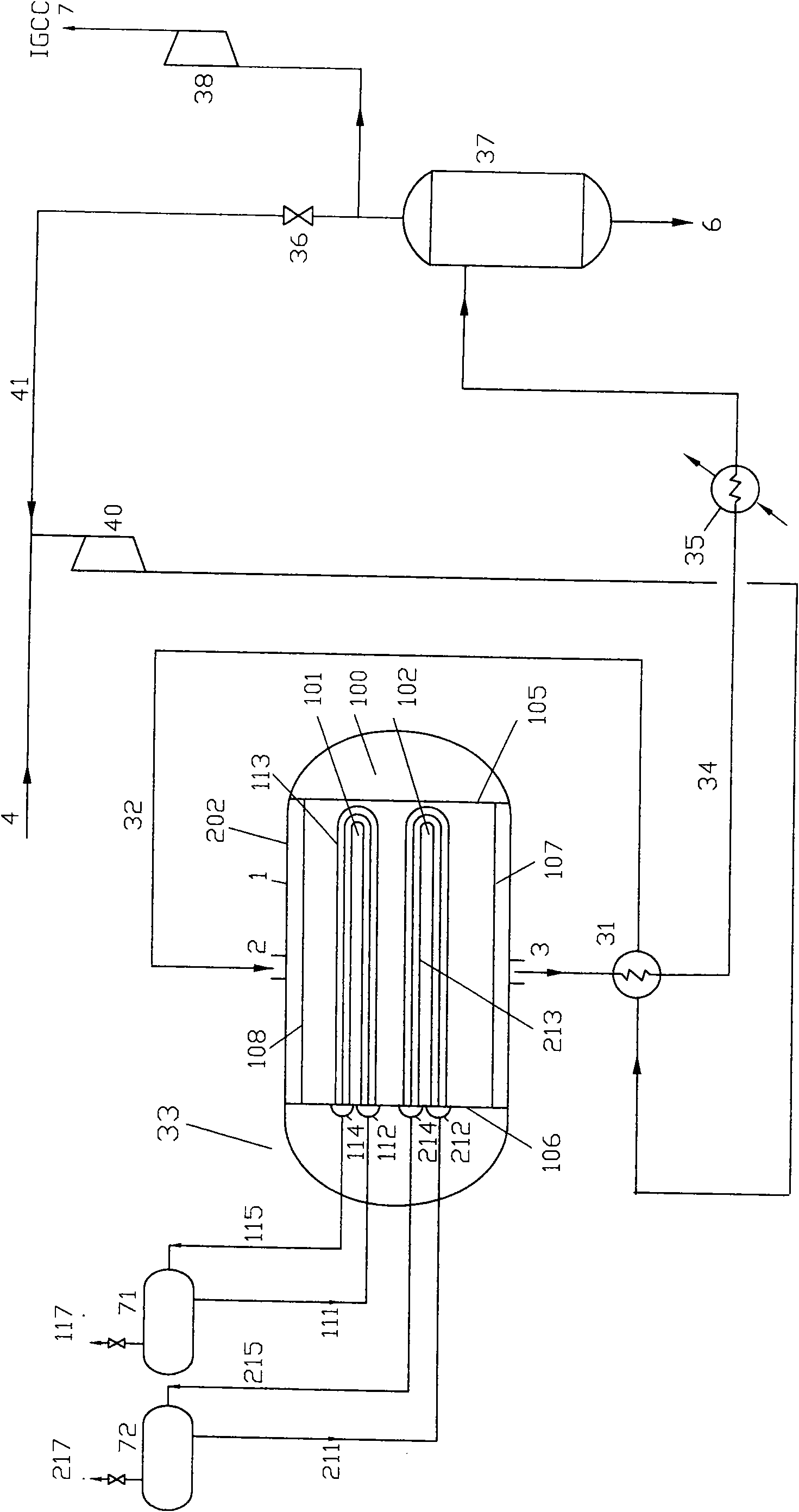

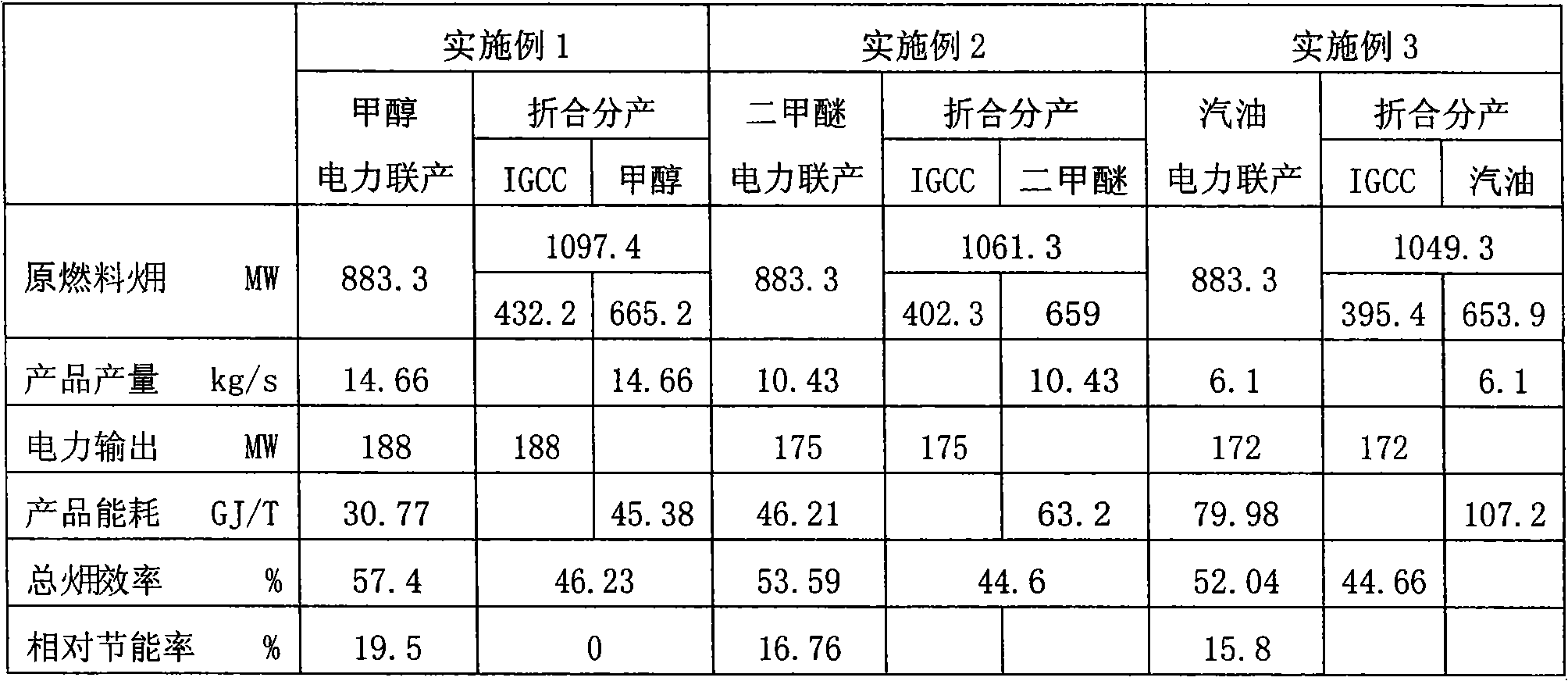

[0026] Embodiment 1: Methanol-electricity polygeneration system with coal synthesis gas, according to figure 1 The raw material 1 coal consumption shown is 31.6kg / s, the gasification 2 coal and other feed effective energy (hereinafter referred to as exergy) total exergy is 883.3MW, and the gas volume of the purified syngas after purification 3 into synthesis 5 is 2.778kmol / s, The gas composition and flow rates are shown in Table 1. In the chemical synthesis process 5, the attached figure 2 According to the process, the synthesis gas passes through the synthesis of methanol once, and the synthesis gas 32 heated to about 220°C by the heat exchanger 31 with the tower gas 34 under the pressure of 5Mpa enters the methanol synthesis reactor 33, and at about 100M 3 Under the action of a methanol catalyst, the H in methanol synthesis gas at a temperature of about 220-270°C 2 and CO, CO 2 Synthesize CH 3 OH, the vaporization temperature of the water in the heat exchange tube group...

Embodiment 2

[0030] Embodiment 2: Coal-to-synthesis gas dimethyl ether-power polygeneration system, also used figure 1 Shown operation, what generate in the operation 5 that is different from example 1 is dimethyl ether, use figure 2 The process shown is one-step synthesis gas production of dimethyl ether, the difference is that the reactor 33 uses a bifunctional catalyst composed of a copper-based methanol catalyst A and a gamma alumina or molecular sieve dehydration catalyst B of about 150M 3 Substitute the copper-based methanol synthesis catalyst in Example 1 to synthesize dimethyl ether at a pressure of 6Mpa and a temperature of 300°C. The temperature of the catalyst in the synthesis of dimethyl ether can also be used as the heat transfer medium in two sets of water-cooled heat exchange tubes, such as the vaporization temperature of water and The pressure is independently adjusted and controlled to achieve the purpose of reducing the temperature difference and uniform temperature bala...

Embodiment 3

[0031] Embodiment 3: coal-to-synthesis gas to gasoline-power polygeneration system, using figure 1 The process shown and figure 2 Reactor and flow process, iron or cobalt based Fischer-Tropsch synthesis catalyst 120M is used in reactor 33 3 , with the same gas volume and composition of syngas in Table 1, 6.1kg / s synthetic oil was produced at 4Mpa and a temperature of about 250°C, and 172MW of power was transmitted externally. For the data of co-production and converted sub-production, see Example 3 in Attached Table 2. The production-to-production relative energy-saving rate is 15.8%.

[0032] Table 2 Chemical-electricity polygeneration and production performance comparison table

[0033]

[0034] Beneficial effect

[0035] Compared with the prior art, the present invention has significant advantages. One is that different vaporization pressures and vaporization temperatures of the heat exchange medium are used for the catalyst layer heat exchange tube group in differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com