High corrosion resistant surfacing electrode

A surfacing electrode, high corrosion resistance technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of limited application and high cost, and achieve excellent corrosion resistance, beautiful shape, and high temperature strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

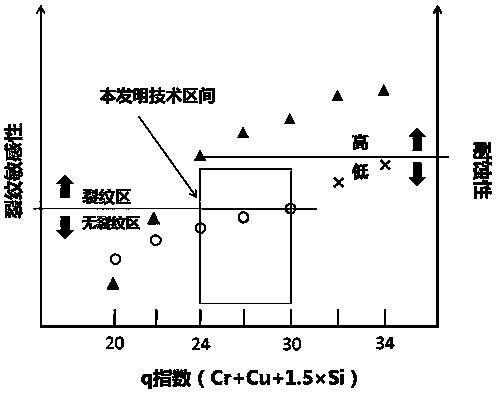

Image

Examples

Embodiment 1-3

[0040] Electrode 4.0mm, vertical welding, current 100-130A, welding speed 2.0mm / s.

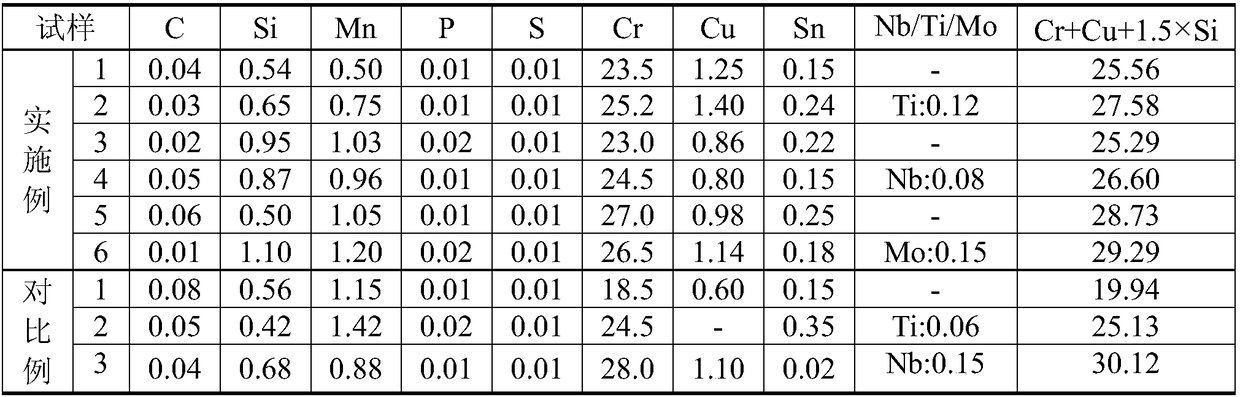

[0041] The chemical composition of the surfacing layer is shown in Table 1, the corrosion performance is shown in Table 2, and the process performance and mechanical properties are shown in Tables 3 and 4. Embodiment 4-6:

Embodiment 4-6

[0042] Welding rod 4.0mm, vertical welding, current 110-150A, welding speed 2.8mm / s.

[0043] The chemical composition of the surfacing layer is shown in Table 1, the corrosion performance is shown in Table 2, and the process performance and mechanical properties are shown in Tables 3 and 4. Comparative example 1-3:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com