Method for improving mixed C4 chemical industry exploitation value

A technology of mixing C4 and C4 chemicals, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of low comprehensive utilization rate of chemical utilization value, and achieve the effect of improving value and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

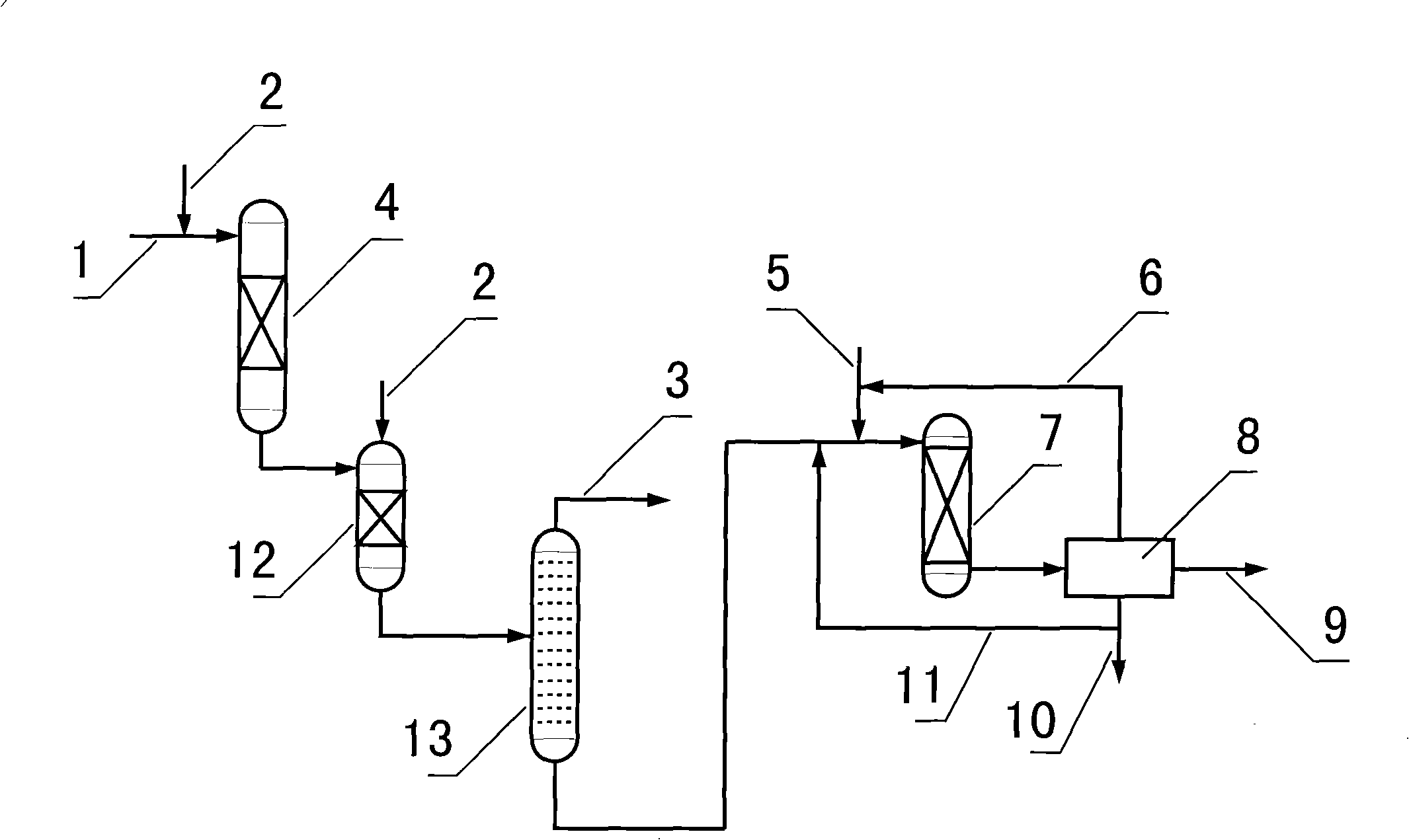

Embodiment 1

[0026] according to figure 1 As shown, the mixed carbon four composition (weight %) is: butadiene: 40.0%, isobutene: 12.0%, butene-1: 18.0%, butene-2: 18.2%, butane: 11.8%. Adopting the technical process of the present invention, the selective hydrogenation reaction catalyst is aluminum oxide supported metal palladium, the hydrogen-oil ratio of the reaction feed is 150:1 (volume), and the reaction space velocity is 3 hours -1 , the reactor inlet temperature is 60°C, and the reaction pressure is 3.0MPa; the hydroisomerization reaction catalyst is aluminum oxide supported metal palladium, the reaction feed hydrogen oil ratio is 90:1 (volume), the reaction temperature is 40°C, and the reaction The pressure is 0.8MPa; the refining separation tower is a floating valve tower with 80 trays, and the operating pressure at the top of the tower is 0.4MPa; the disproportionation reaction catalyst is tungsten oxide, the reaction temperature is 280°C, the reaction pressure is 2.8MPa, and th...

Embodiment 2

[0028] according to figure 1 As shown, the mixed carbon four composition (weight %) is: butadiene: 30.0%, isobutene: 12.0%, butene-1: 18.0%, butene-2: 18.2%, butane: 21.8%. Adopting the technical process of the present invention, the selective hydrogenation reaction catalyst is aluminum oxide supported metal nickel, the hydrogen-oil ratio of the reaction feed is 100:1 (volume), and the reaction space velocity is 5 hours -1 , the reactor inlet temperature is 100°C, and the reaction pressure is 3.5MPa; the hydroisomerization reaction catalyst is aluminum oxide supported metal nickel, the hydrogen-oil ratio of the reaction feed is 60:1 (volume), the reaction temperature is 70°C, and the reaction The pressure is 1.2MPa; the refining separation tower is a sieve tray tower with 100 trays, and the operating pressure at the top of the tower is 0.6MPa; the disproportionation reaction catalyst is tungsten oxide, the reaction temperature is 300°C, the reaction pressure is 3.2MPa, and the...

Embodiment 3

[0030] according to figure 1 As shown, the mixed carbon four composition (weight %) is: butadiene: 20.0%, isobutene: 15.0%, butene-1: 18.0%, butene-2: 18.2%, butane: 28.8%. Adopting the technical process of the present invention, the selective hydrogenation reaction catalyst is aluminum oxide supported metal palladium, the hydrogen-oil ratio of the reaction feed is 60:1 (volume), and the reaction space velocity is 8 hours -1 , the reactor inlet temperature is 40°C, and the reaction pressure is 2.5MPa; the hydroisomerization reaction catalyst is aluminum oxide supported metal nickel, the reaction feed hydrogen-oil ratio is 30:1 (volume), the reaction temperature is 55°C, and the reaction The pressure is 0.9MPa; the refining separation tower is a packed tower, the packing height is 28 meters, and the operating pressure at the top of the tower is 0.8MPa; the disproportionation reaction catalyst is tungsten oxide, the reaction temperature is 330°C, the reaction pressure is 2.2MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com