Full-biodegradable high-barrier vacuum evaporation film and preparation method thereof

A biodegradable, vacuum film technology, applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve unsatisfactory problems, achieve the effect of solving environmental problems, high utilization value, and excellent barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

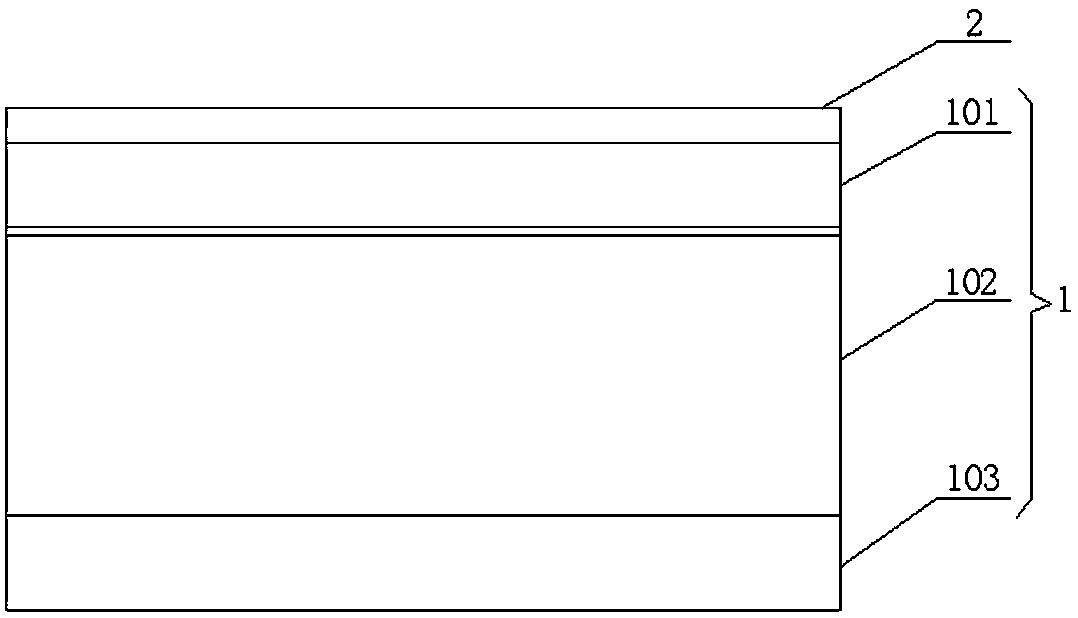

[0029] A biodegradable high-barrier vacuum evaporation film substrate, the film is composed of a high-barrier coating layer 2 and a film substrate layer 1 from top to bottom, and the film substrate layer 1 is composed of an upper surface layer 101 and a core layer 102 , And the lower surface layer 103 is composed.

[0030] The upper surface layer 101 is an evaporation surface, and by weight percentage, the material used for the upper surface layer 101 is 98% modified polylactic acid Composed of 2% anti-adhesion additive masterbatch, the thickness is 1-2μm. Copolymers in this example include Purchased from Toyobo Co., Ltd.

[0031]The core layer 102 provides strength to the substrate and is composed of 100% crystalline polylactic acid (NatureWorks 4060D).

[0032] The lower surface layer 103 is another functional surface. By weight percentage, the lower surface layer 103 is composed of 98% crystalline polylactic acid (NatureWorks Ingeo 4060D) and 2% anti-blocking additiv...

Embodiment 2-3

[0041] A biodegradable gas-barrier evaporation film substrate, the film is composed of a high-barrier coating layer 2 and a film substrate layer 1 from top to bottom, and the film substrate layer 1 is composed of an upper surface layer 101 and a core layer 102 , And the lower surface layer 103 is composed of.

[0042] Upper surface layer 101 is the coating surface, by weight percentage, upper surface layer 101 is made of 98% modified polylactic acid 2% anti-adhesion additive masterbatch with a thickness of 1-2μm.

[0043] The core layer 102 provides strength for the substrate, and the material used is 100% crystalline polylactic acid (NatureWorks Ingeo4060D), with a thickness of 12-100 μm.

[0044] The lower surface layer 103 is another functional surface. By weight percentage, the lower surface layer 103 is composed of 98% crystalline polylactic acid (NatureWorks Ingeo 4060D) and 2% anti-blocking additive masterbatch, with a thickness of 1-2 μm.

[0045] Concrete preparati...

Embodiment 4-5

[0055] A biodegradable gas-barrier vapor-deposited film substrate, which consists of a high-barrier coating layer 2 and a film substrate layer 1 from top to bottom. The film substrate layer 1 is composed of an upper surface layer 101, a core layer 102, and The lower surface layer 103 is composed.

[0056] Upper surface layer 101 is the coating surface, by weight percentage, upper surface layer 101 is made of 68% modified polylactic acid 2% anti-adhesion additive masterbatch composition, the balance is 30% glycidyl methacrylate grafted polylactic acid (PLA-g-GMA) (formulation of embodiment 4) or maleic anhydride grafted polylactic acid (PLA-g-GMA) g-MAH)) (formulation of Example 5), the thickness is 1-2 μm.

[0057] The core layer 102 provides strength for the substrate, and the materials used are 98% crystalline polylactic acid (NatureWorks Ingeo4060D), 2% polylactic acid-based amide type nucleating agent masterbatch, and the thickness is 12-60 μm.

[0058] The lower surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com