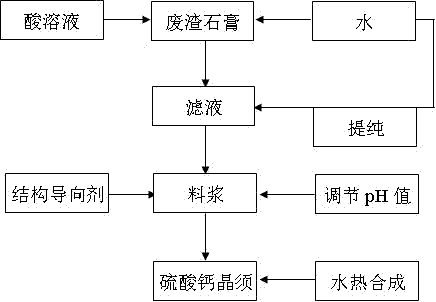

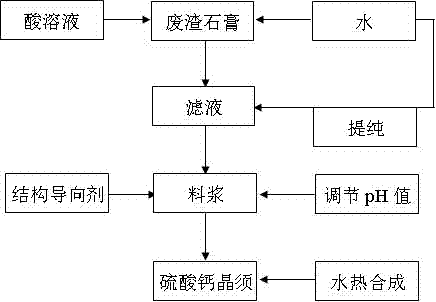

Method for preparing calcium sulfate crystal whisker from many kinds of industrial waste residue gypsum serving as raw materials

A technology of calcium sulfate whiskers and industrial waste residues, which is applied to the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth, can solve the problems of wasting manpower and material resources, slow hydration speed, and insoluble in water. The effect of short production cycle, moderate equipment requirements and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

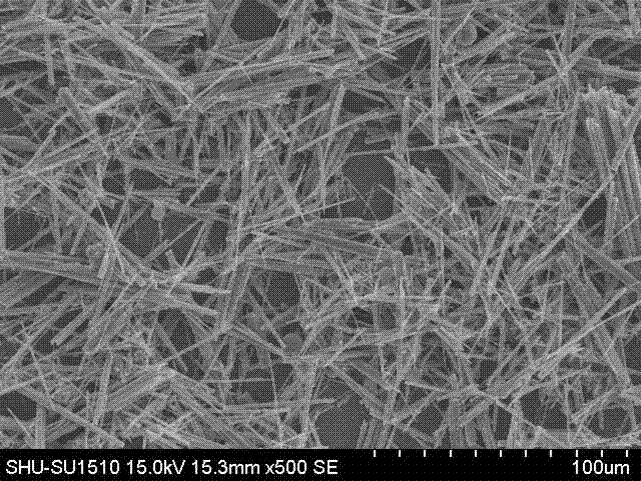

[0020] Example 1: Combine phosphogypsum, desulfurized gypsum and fluorine gypsum in any mass ratio and then mix them with nitric acid solution at a mass ratio of 8:100. The concentration of nitric acid is 2.5mol / L. After heating up to calcium sulfate gradually dissolved, filter while hot Adjust the solid-to-liquid ratio of calcium sulfate and water in the filtrate to be 1:10, add wt.5% magnesium chloride to make slurry as structure-directing agent, adjust slurry pH value to be 3, slurry is transferred in the reactor, control The reaction temperature is 140°C, and the reaction time is 2h; after the reaction is completed, cool to room temperature, filter, wash, and control the drying time to 120min at 80°C to obtain high-quality calcium sulfate whiskers. Calcium sulfate hemihydrate (CaSO 4 ·(1 / 2)H 2 O), the scanning electron microscope shows that the average diameter of the whiskers is 1 μm, the average length is 120 μm, and the whiteness of the whiskers measured by the whitene...

Embodiment 2

[0021] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that the reaction time is 8h. Calibrated as anhydrous calcium sulfate (CaSO 4 ), the scanning electron microscope shows that the average diameter of the whiskers is 0.8 μm, the average length is 100 μm, and the whiteness of the whiskers measured by the whiteness meter is 95.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com