Preparation technology of high-content oat beta-glucan dietary fiber powder

A dietary fiber powder and a preparation process technology, which are applied in the preparation methods of peptides, the functions of food ingredients, and protein-containing food ingredients, etc., can solve the problem that the by-products of the process cannot be well collected and extracted for β-glucan dietary fiber extraction. problems such as low rate of use, to achieve the effect of increasing the scope of use, making full use of it, and achieving a high rate of collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

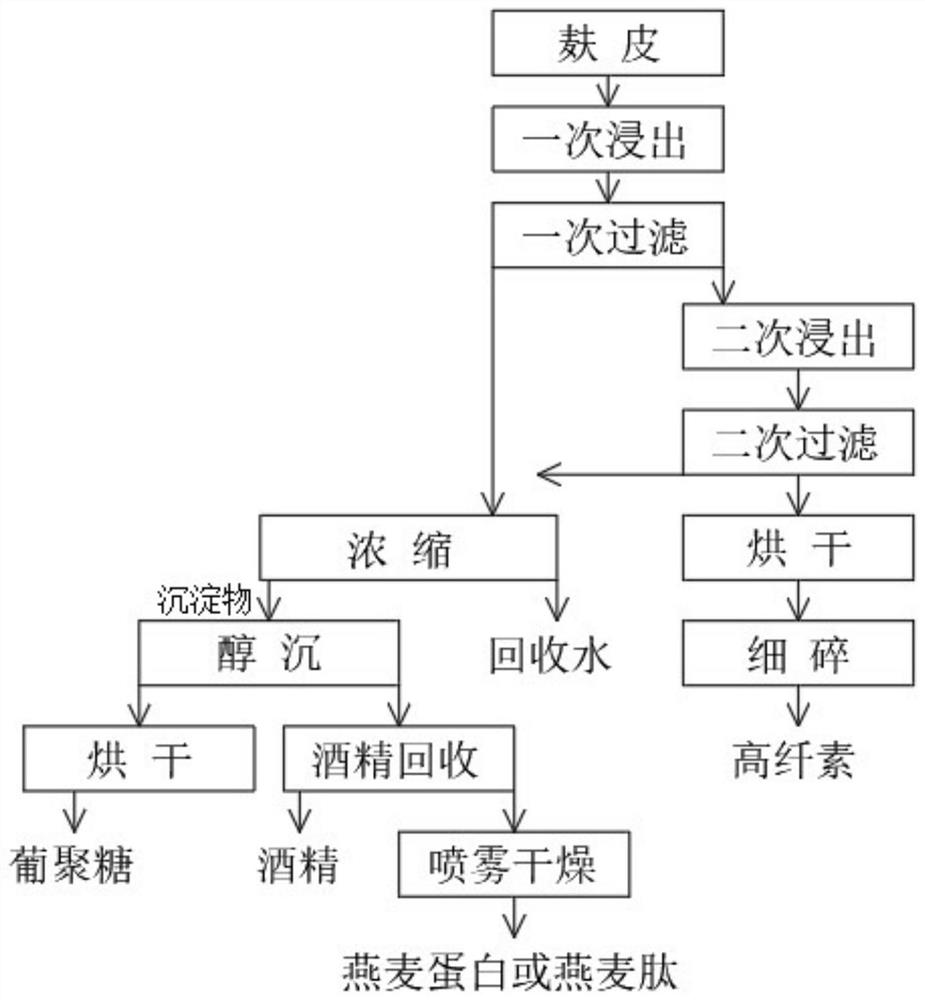

[0029] like figure 1 As shown, embodiments of the present invention provide a high level of oat β-glucan dietary fiber powder, including the following steps:

[0030] Step one, leaching once

[0031] The oat bran is mixed inside the container, and then oat bran: warm water is mixed in a ratio of 1.5: 15, and then the amylase is put into amylase inside the container and mix uniform, amylase and oat bran mass ratio of 0.1: 200, At the same time, the cellulase and oat bran mass ratio are 0.08: 150, and the cellulase and amylase are added to the container after stirring, standing for 2 hours, standing for a room temperature Environment is 20 degrees Celsius, get leaching raw materials, oat bran has rich β-glucan, oat bran is oatmeal contains the most dietary fiber, especially the most abundant beta-glucan, beta-glucogen Sugar is soluble dietary fibers are known to lower blood fat active ingredients, while contributing to intestinal health, and oatmeal is known as aristocratic dietary ...

Embodiment 2

[0046] like figure 1 As shown, embodiments of the present invention provide a high level of oat β-glucan dietary fiber powder, including the following steps:

[0047] Step one, leaching once

[0048] The oat bran is mixed inside the container, and then oat bran: warm water is mixed in a ratio of volume ratio 1: 15, which is subjected to an amylase to the container and mix uniform, amylase and oat bran mass ratio of 0.03: 130, At the same time, the cellulase and oat bran mass ratio of cellulase and oatmented by 0.03: 120 are added to the container, and the cellulase and amylase are added to the container. After stirring, the standing time is 4 hours, the standing process In 0.8 hours every 0.8 hours, the stirring speed is 800 rpm, and the sedation is 30 degrees Celsius to obtain a leaching material;

[0049] Step 2, one filtering and secondary leaching

[0050] Filtration of the leaching material in step one was filtered using a 100-mesh screen, and the leaching bran was pressed to...

Embodiment 3

[0063] like figure 1 As shown, embodiments of the present invention provide a high level of oat β-glucan dietary fiber powder, including the following steps:

[0064] Step one, leaching once

[0065] The oat bran is mixed inside the container, and then oat bran: warm water is mixed in a ratio of 1.3: 13, and then the amylase is put into amylase inside the container and mix uniform, amylase and oat bran mass ratio 0.07: 170, At the same time, the cellulase and oat bran mass ratio are 0.03: 130 to the container, and the cellulase and amylase are added to the container after stirring, it is allowed to stand, standing for 3 hours, standing for room temperature The environment is 25 degrees Celsius, gets leaching materials, oat bran has a rich β-glucan, oat bran is oatmeal contains the most dietary fiber, especially the most abundant beta-glucan, beta-glucogenic Sugar is soluble dietary fibers are known to lower blood fat active ingredients, while contributing to intestinal health, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com