Cellulose-containing resin composition and cellulosic ingredient

A resin composition and cellulose fiber technology, applied in the field of cellulose preparations, can solve the problems of increased weight and high specific gravity of resin moldings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0504] [Raw materials and evaluation methods]

[0505] Hereinafter, the raw materials and evaluation methods used will be described.

[0506] 《Thermoplastic resin》

[0507] Polyamide

[0508] Polyamide 6 (hereinafter referred to as PA)

[0509] "UBE Nylon 1013B" available from Ube Industries, Ltd.

[0510] The carboxyl end group ratio is ([COOH] / [all end groups])=0.6

[0511] Polypropylene

[0512] Homopolypropylene (hereinafter referred to as PP)

[0513] "Prime Polypro J105B" available from PRIME POLYMER

[0514] MFR measured at 230°C according to ISO1133=9.0g / 10min

[0515] Maleic acid modified polypropylene (hereinafter referred to as MPP)

[0516] "UMEX 1001" available from Sanyo Chemical Industry Co., Ltd.

[0517] MFR measured at 230°C according to ISO1133 = 230g / 10min

[0518] "Cellulose Composition"

[0519] Cellulose whiskers (hereinafter sometimes abbreviated as CW)

[0520] Commercially available DP pulp (average degree of polymerization: 1600) was trim...

Embodiment A1~46 and comparative example A1~10

[0638] Polyamide, polypropylene, acid-modified polypropylene, cellulose whiskers, and cellulose fibers were mixed in the ratios recorded in Tables A3 to 5, and the TEM48SS extruder manufactured by Toshiba Machine Co., Ltd. was used at a screw speed of 350rpm, Melt-kneading was carried out at a discharge rate of 140 kg / hr, and after vacuum devolatilization, it was extruded in a strand form from a die, cooled in a water bath, and granulated. The pellets were cylindrical in shape with a diameter of 2.3 mm and a length of 5 mm.

[0639] They were evaluated according to the above-mentioned evaluation methods.

[0640]

[0641]

[0642]

[0643]

[0644] Based on polyamide resin, the ratio of cellulose fibers and cellulose whiskers was changed.

[0645] It can be seen that compared with Comparative Example A2 in which cellulose fibers were used alone, in Example A5 in which cellulose whiskers were used in combination, the defect rate, fluidity (minimum filling pressure)...

Embodiment A47~57

[0653] With respect to 100 mass parts of polyamides, mix 15 mass parts of cellulose whiskers, 5 mass parts of cellulose fibers and 5 mass parts of organic components shown in Table A6, utilize the TEM48SS extruder manufactured by Toshiba Machine Co., Ltd., at the screw speed Melt-kneading was performed at 350 rpm and a discharge rate of 200 kg / hr, and after vacuum devolatilization, it was extruded from a die in a strand form, cooled in a water bath, and granulated. The pellets were cylindrical in shape with a diameter of 2.3 mm and a length of 5 mm.

[0654] They were evaluated according to the above-mentioned evaluation methods.

[0655]

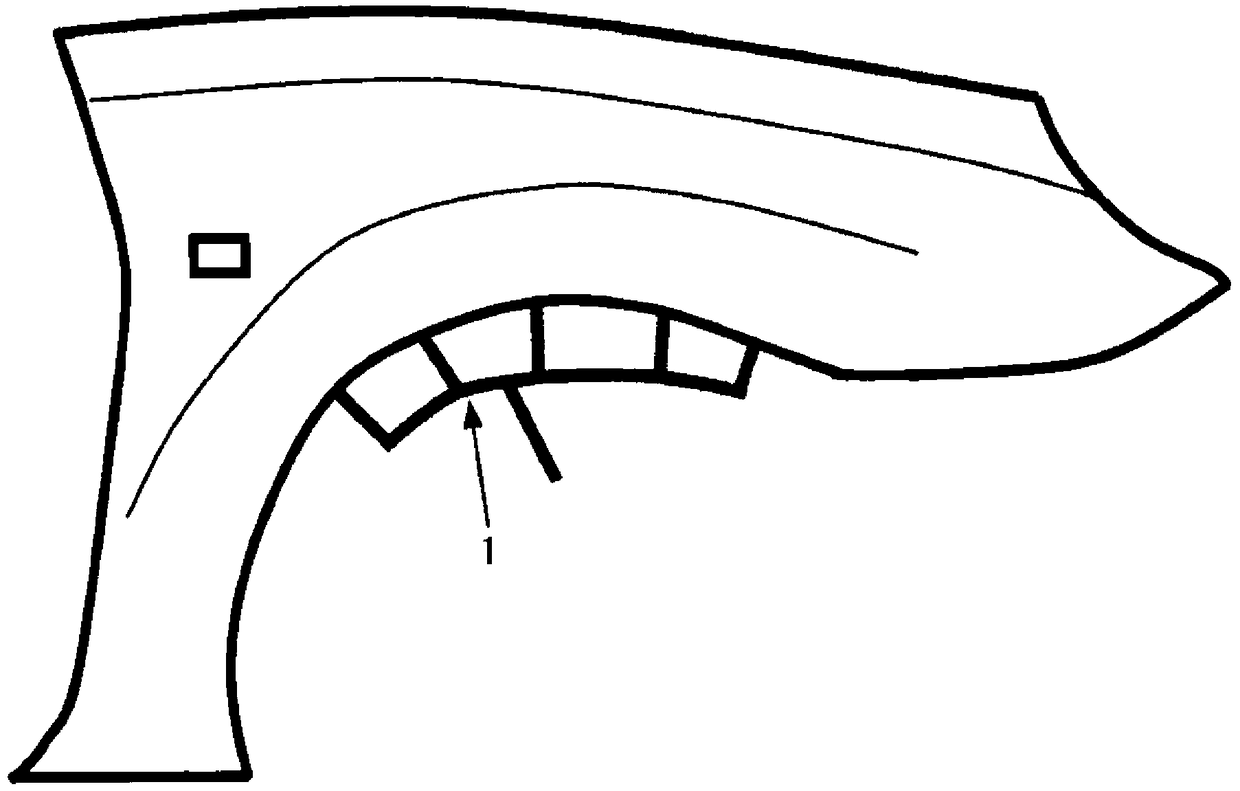

[0656] Using various substances as organic components, as a result, in Examples A49 to 52 and 54, the fender defect rate showed zero. In addition, in these examples, improvements in the rate of increase in the tensile yield strength, the expansion rate of the molded sheet, and the coefficient of variation of the coefficient of linear ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com