Micro-nano cellulose preparation method

A technology of micro-nano cellulose and cellulose, which is applied in the fields of fiber raw material processing, textile and papermaking, raw material separation, etc., and can solve problems such as increasing the difficulty of product separation, difficulty in ensuring nano-cellulose products, and limiting the application of micro-nano cellulose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

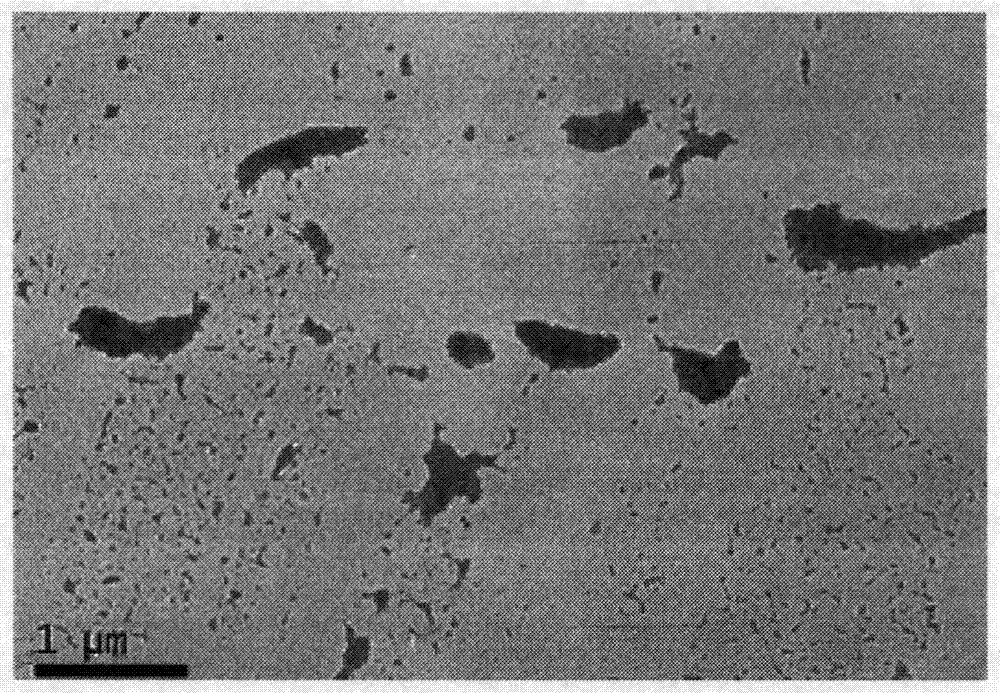

Image

Examples

Embodiment 1

[0022] The natural cellulose material is made into micro-nano cellulose by a purely physical method, including the following steps:

[0023] (1) Get natural cellulose material, such as 100 grams of refined cotton or wood pulp, first through high-energy electron beam irradiation, the irradiation dose is 50-350kGy, and the best high-energy electron beam irradiation dose is 150-250kGy;

[0024] (2) After the above steps, use an impact mill to dry coarsely pulverize the irradiated refined cellulose to obtain microcrystalline cellulose with an average fineness of 20-400 mesh, considering the comprehensive cost and comprehensive pulverization Efficiency, the best fineness of cellulose is 100-300 mesh;

[0025] (3) After the above steps, add these coarse cellulose powders to 99 times of water, and after mixing evenly, add them into the feeding chamber with power ultrasonic pretreatment for ultrasonic dispersion and preactivation;

[0026] (4) After the above steps, enter the water m...

Embodiment 2

[0028] Use 100 grams of refined cotton, first irradiated by high-energy electron beams, and the irradiation dose is 150kGy. These irradiated refined cottons were coarsely pulverized with an impact pulverizer to obtain microcrystalline cellulose with an average fineness of 200 mesh. Then add these coarse cellulose powders to 99 times of water, after mixing evenly, add them into the feeding chamber with power ultrasonic pretreatment for ultrasonic dispersion and pre-activation, and then enter the colloid mill for fine pulverization, repeated cycles Pulverize to finally obtain the micro-nano cellulose product, the concentration of its aqueous dispersion is 1% (weight %), and it is a white paste.

[0029] The final fineness of the micro-nano cellulose reaches between 100-600nm.

Embodiment 3

[0031] Use 100 grams of paper pulp and irradiate it with a high-energy electron beam at a dose of 250 kGy. These irradiated refined cottons were coarsely pulverized with an impact pulverizer to obtain microcrystalline cellulose with an average fineness of 240 mesh. Then add these coarse cellulose powders to 99 times of water, after mixing evenly, add them into the feeding chamber with power ultrasonic pretreatment for ultrasonic dispersion and pre-activation, and then enter the colloid mill for fine pulverization, repeated cycles Pulverize to finally obtain the micro-nano cellulose product, the concentration of its aqueous dispersion is 1% (weight %), and it is a white paste.

[0032] The final fineness of the micro-nano cellulose reaches between 80-500nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com