High-efficiency environment-friendly cationic fibrillating cellulose preparation method

A cationic and cellulose technology, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problems of long time consumption, drop, and high dosage of quaternary ammonium salt reagents, and achieve good transparency, mild environment, and high DPv Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

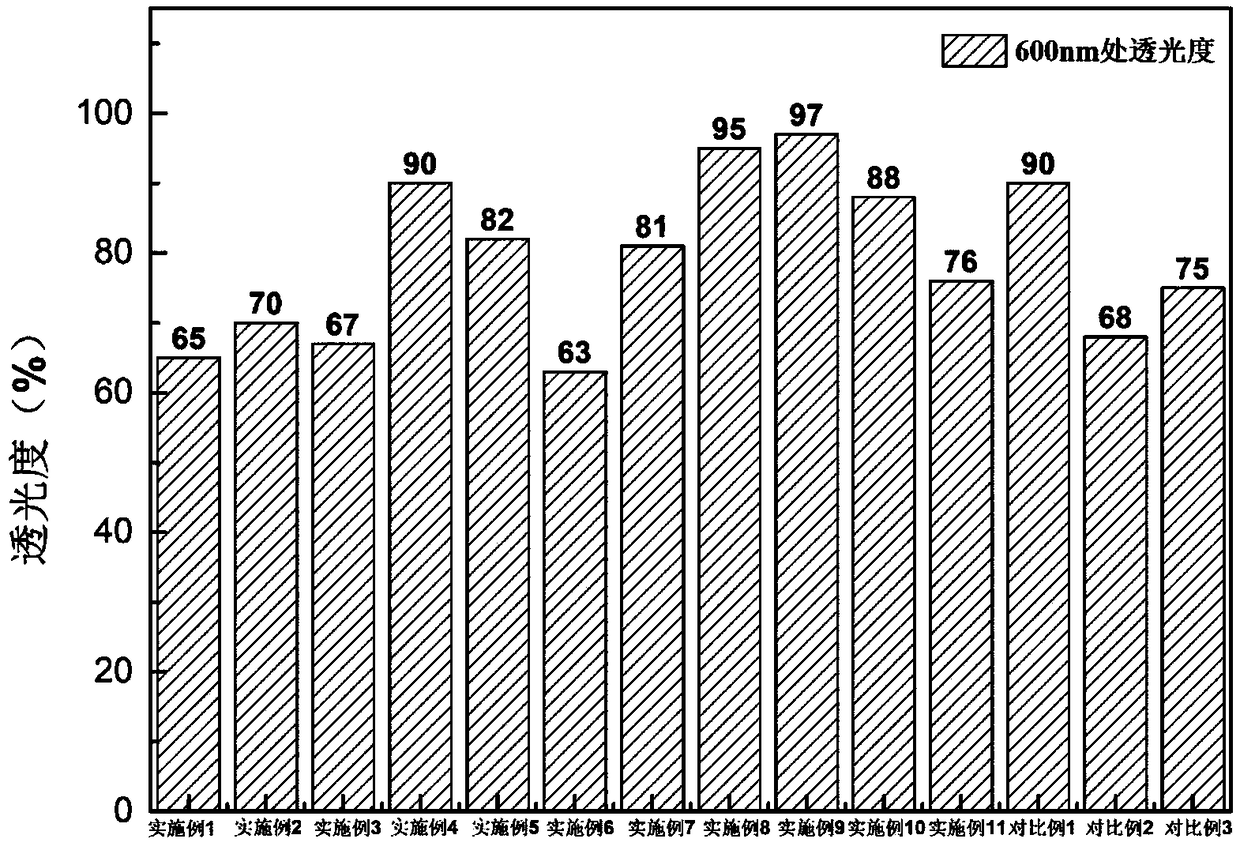

Examples

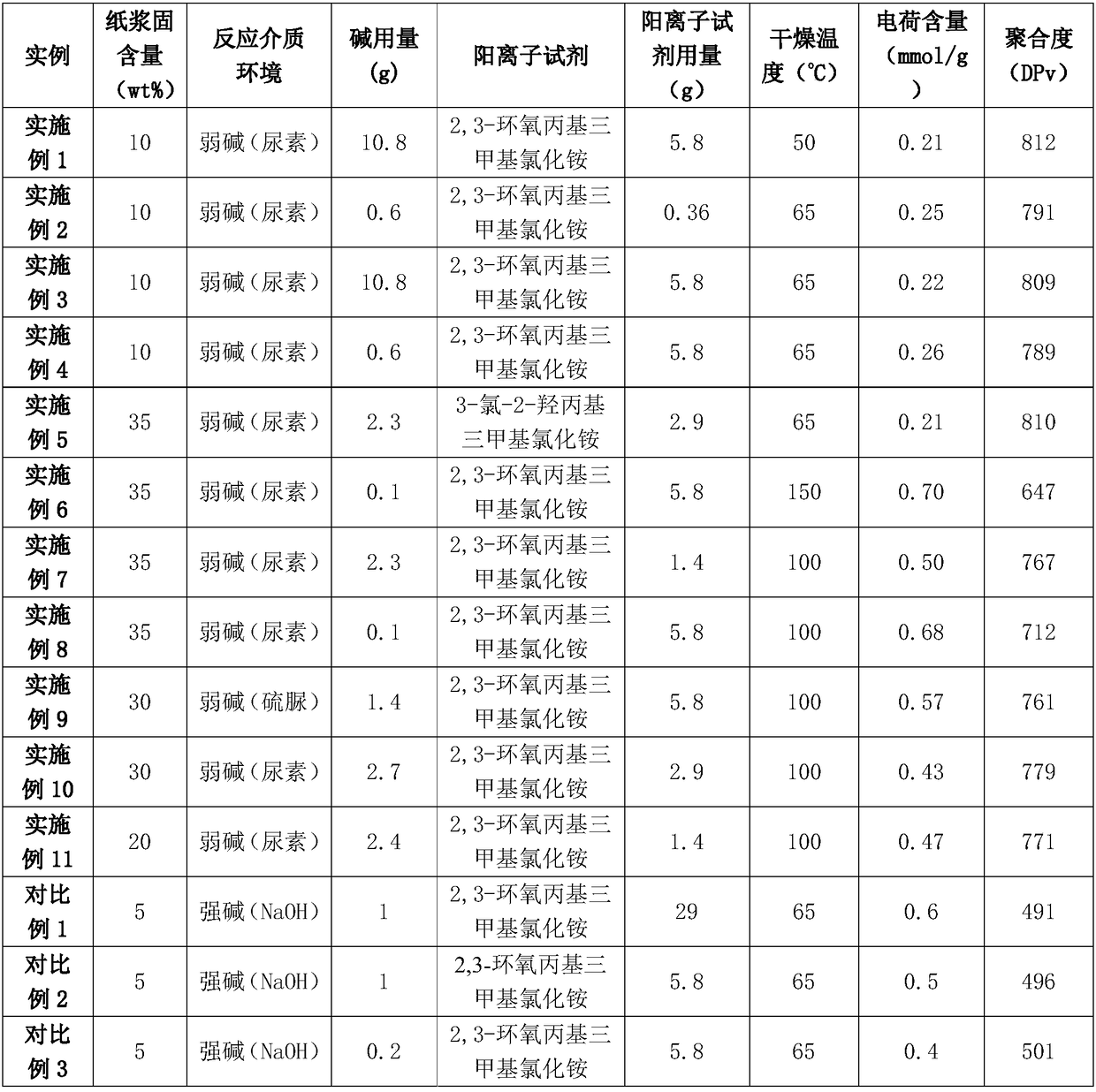

Embodiment 1

[0023] The process of preparing Q-NFC under weak alkaline conditions is as follows:

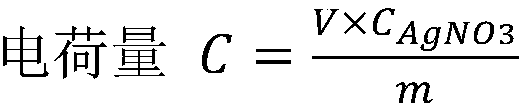

[0024] Weigh 10.8g of urea and dissolve it in 10g of wet pulp. After all of it is dissolved, add 5.8g of 2,3-epoxypropyltrimethylammonium chloride, and heat the mixture in an oven at 50°C to constant weight. Then fully disperse the dry slurry with deionized water, and then filter and wash until the filtrate is washed with AgNO 3 The solution is tested until there is no chloride ion present. Finally, by mechanically treating the washed slurry, a transparent NFC dispersion with a positive charge on the surface is obtained.

Embodiment 2

[0026] The process of preparing Q-NFC under weak alkaline conditions is as follows:

[0027] Weigh 0.6g of urea and dissolve it in 10g of wet bamboo pulp. After all of it is dissolved, add 0.36g of 2,3-epoxypropyltrimethylammonium chloride, and heat the mixture in an oven at 65°C to constant weight. Then fully disperse the dry slurry with deionized water, and then filter and wash until the filtrate is washed with AgNO 3 The solution is tested until there is no chloride ion present. Finally, by mechanically treating the washed slurry, a transparent NFC dispersion with a positive charge on the surface is obtained.

Embodiment 3

[0029] The process of preparing Q-NFC under weak alkaline conditions is as follows:

[0030] Weigh 10.8g of urea and dissolve it in 9g of water, add 1g of dry bamboo pulp into the urea aqueous solution, after all dissolve, add 5.8g of 2,3-epoxypropyltrimethylammonium chloride, put the mixture in 65℃ The oven was heated to constant weight. Then fully disperse the dry slurry with deionized water, and then filter and wash until the filtrate is washed with AgNO 3 The solution is tested until there is no chloride ion present. Finally, by mechanically treating the washed slurry, a transparent NFC dispersion with a positive charge on the surface is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com