Carbon nanotube regenerated bamboo fibers and production method therefor

A technology of carbon nanotubes and production methods, applied in the field of carbon nanotube regenerated bamboo fiber and its production, can solve the problems of unknown regenerated cellulose fiber composite fiber, improve mechanical properties and electrical conductivity, facilitate dispersion, improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

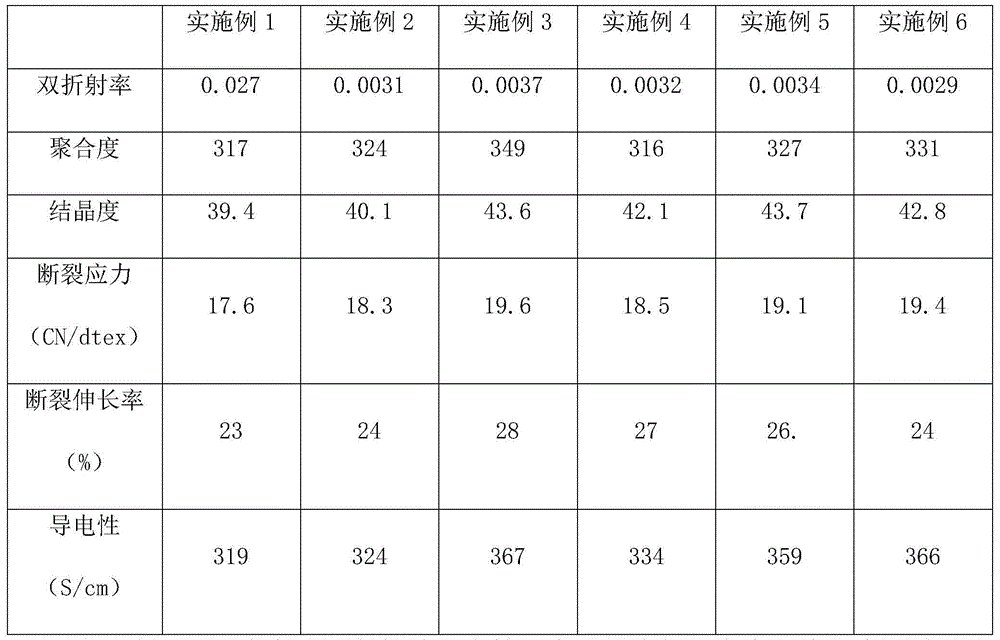

Examples

Embodiment 1

[0027] (1) After air-drying the bamboo slices of light bamboo and moso bamboo, immerse them in water for pre-hydrolysis, and then after secondary cooking, beating, washing, bleaching, neutralization, impurity removal, pulping, and drying to obtain a viscosity-average molecular weight of 40,000 recycled bamboo fiber pulp.

[0028] (2) Immerse carbon nanotubes in a strong nitric acid solution, ultrasonicate at 35°C for 5 hours, cool to room temperature and filter to obtain filter residues, wash and filter the filter residues until the filtrate is neutral, and dry to obtain hydrophilic modified carbon nanotubes with a length of 0.03mm .

[0029] (3) by weight, 5 parts of modified carbon nanotubes prepared by step (2) are dispersed in 100 parts of deionized water, ultrasonically dispersed, added to 50 parts of regenerated bamboo fiber pulp prepared by step (1), And add 10 parts of N-methylmorpholine aqueous solution, stir evenly, obtain spinning stock solution, obtain through vis...

Embodiment 2

[0031] (1) After air-drying the bamboo chips of light bamboo and moso bamboo, immerse them in water for pre-hydrolysis, and then after secondary cooking, beating, washing, bleaching, neutralization, impurity removal, pulping, and drying to obtain a viscosity-average molecular weight of 44000 recycled bamboo fiber pulp.

[0032] (2) Immerse the carbon nanotubes in strong nitric acid or strong sulfuric acid solution, ultrasonicate at 35°C for 10 hours, cool to room temperature and filter to obtain the filter residue, wash and filter the filter residue until the filtrate is neutral, and dry to obtain a hydrophilic modification with a length of 0.01mm carbon nanotubes.

[0033] (3) by weight, 10 parts of modified carbon nanotubes prepared by step (2) are dispersed in 100 parts of deionized water, ultrasonically dispersed, added to 100 parts of regenerated bamboo fiber pulp prepared by step (1), And add 10 parts of N-methylmorpholine aqueous solution, stir evenly, obtain the spinn...

Embodiment 3

[0035] (1) After air-drying the bamboo slices of light bamboo and moso bamboo, immerse them in water for pre-hydrolysis, and then after secondary cooking, beating, washing, bleaching, neutralization, impurity removal, pulping, and drying to obtain a viscosity-average molecular weight of 41675 recycled bamboo fiber pulp.

[0036] (2) Immerse carbon nanotubes in strong nitric acid or strong sulfuric acid solution, ultrasonicate at 35°C for 7 hours, cool to room temperature and filter to obtain filter residue, wash and filter the filter residue until the filtrate is neutral, and dry to obtain a hydrophilic modification with a length of 0.02mm carbon nanotubes.

[0037] (3) by weight, 10 parts of modified carbon nanotubes prepared by step (2) are dispersed in 100 parts of deionized water, ultrasonically dispersed, added to 50 parts of regenerated bamboo fiber pulp prepared by step (1), And add 10 parts of N-methylmorpholine aqueous solution, stir evenly, obtain spinning dope, obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com