Technology and equipment for preparing artificial fiber filament non-woven fabric on basis of dry spinning technique

A technology of filament non-woven fabrics and man-made fibers, applied in the field of textiles, can solve the problems of increasing the production cost of non-woven fabrics, increasing the complexity of the process, and no one has thought of it, so as to improve the washing effect, save process steps, and achieve good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

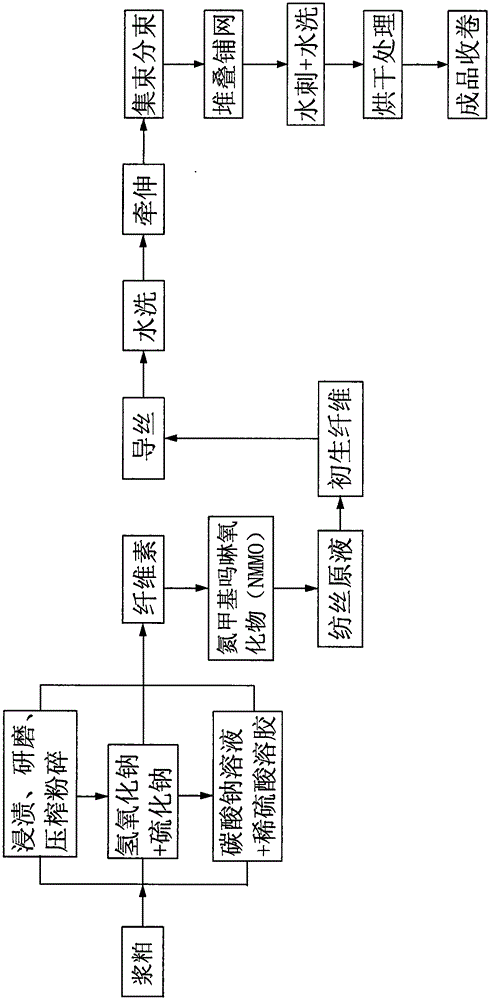

[0047] (1) Preparation of spinning stock solution: Pulp raw materials are obtained from trees, grasses and other raw materials. The pulp raw materials are sequentially impregnated, ground, pressed and pulverized, and the sulfate slurry obtained after cooking with a mixture of sodium hydroxide and sodium sulfide , the sulfate slurry is washed in running water, dehydrated; then alternately dipped in sodium carbonate solution and dilute sulfuric acid sol-pressed dry-washed twice to obtain cellulose; the cellulose is added to nitrogen methylmorpholine oxide ( NMMO) solution, and obtain spinning dope after defoaming;

[0048] (2) Solidification reaction of stock solution and recovery of nitrogen methyl morpholine oxide (NMMO) In the tunnel, the action of the spinning dope in the hot air flow makes the nitrogen methyl morpholine oxide (NMMO) in the thin stream of the dope volatilize quickly, and the volatilized nitrogen methyl morpholine oxide (NMMO) vapor is carried by the hot air ...

Embodiment 1

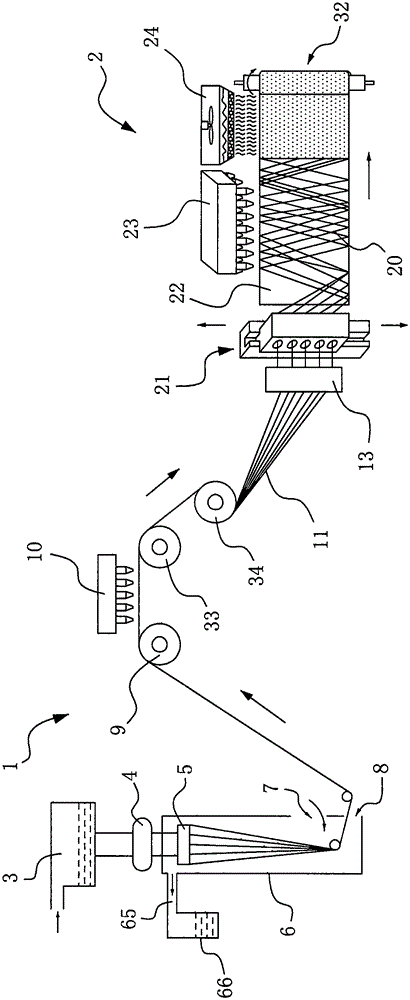

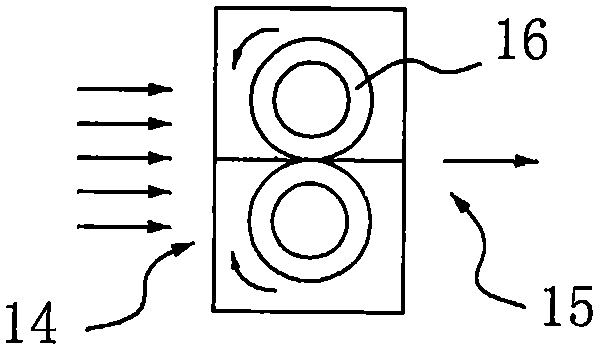

[0059] Such as figure 2 , 3 , 4, 5, and 6, a device for preparing artificial fiber filament non-woven fabrics based on dry spinning technology, consisting of a dry spinning device 1 and a forming device 2, the dry spinning device 1 includes A spinning stock solution container 3 with an injection port, a metering pump 4 connected to the spinning stock solution container 3, a spinneret 5 is connected to the metering pump 4, and the spinning solution for spraying the spinneret 5 The solidified spinning shaft 6, the spinneret 5 extends into the spinning shaft 6, the bottom of the spinning shaft 6 is provided with a hot air inlet 7 and an output port 8 for deriving the solidified artificial fiber tow 11, The top of spinning tunnel 6 is provided with hot air outlet 65 and is connected with hot air outlet 65 and is used for reclaiming the collection container 66 of nitrogen methyl morpholine oxide (NMMO), and washing device 10 is set at outlet 8, It also includes a forming device ...

Embodiment 2

[0063] In order to meet the actual production needs, a winding mechanism 32 can be set at the output end of the web forming machine web curtain 22, and the filament fiber web 20 on the web forming machine web curtain 22 is dried by the drying mechanism 24 and then rolled. Mechanism 32 is directly wound and packaged. A drafting roll for improving the strength of the rayon tow 11 can also be optionally arranged between the godet roll 9 and the bundle splitting device 13 , and the drafting roll is composed of a main drafting roll 33 and a secondary drafting roll 34 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com