Recovery method of spinning waste liquor by means of concentrating

A recycling method and waste liquid technology, applied in the field of spinning, can solve the problems of unfavorable cost control and industrial application, low recovery rate of NMMO, waste of resources, etc., and achieve the effect of small footprint, small investment and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

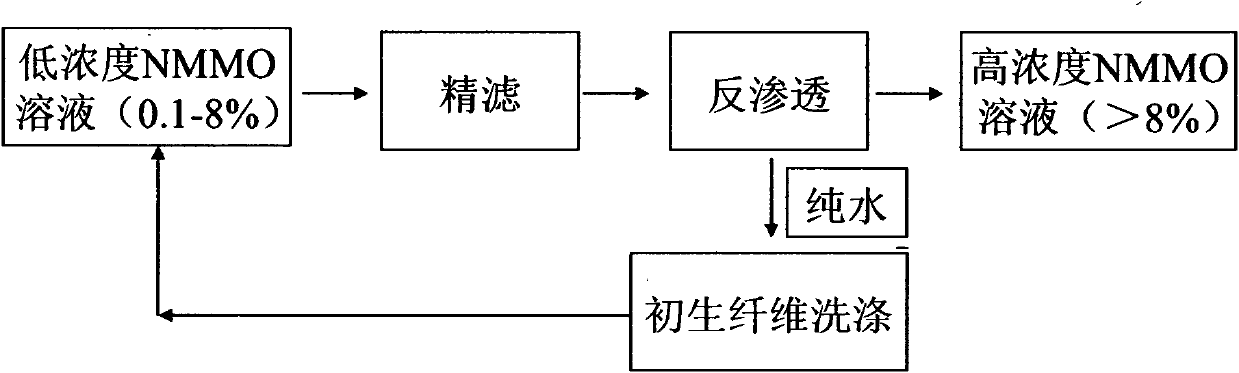

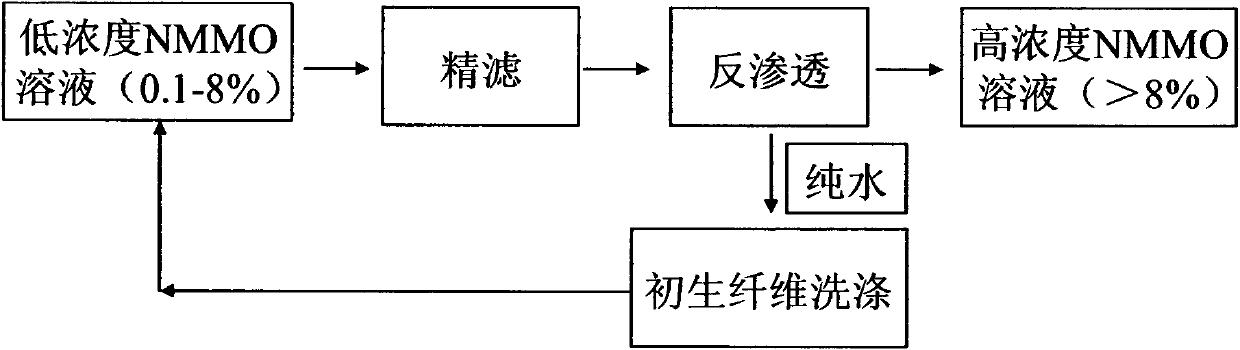

Method used

Image

Examples

Embodiment 1

[0019] a. Pretreatment: Under the water temperature condition of 21° C., pressurize the NMMO low-concentration solution with a mass percent concentration of 1.04% to a pressure of 0.2 MPa. Send it to a 2-micron precision filter for precise pretreatment, and the precision filter is filled with polypropylene fine filter cotton;

[0020] b. Reverse osmosis concentration: Send the filtrate in step a. under the pressure of 2.8MPa into the reverse osmosis membrane module for reverse osmosis concentration treatment. The operating pressure of the reverse osmosis membrane module is 2.8MPa; The reverse osmosis membrane in the module is a roll membrane, and the membrane material is polyamide material;

[0021] c. post-processing: the concentrated water outlet in the b. step obtains a mass percent concentration of 8.6% NMMO high-concentration solution, and the high-concentration NMMO solution is sent to a vacuum distillation tower for further concentrated treatment; the pure water outlet ...

Embodiment 2

[0023] a. Pretreatment: Under the water temperature of 22°C, pressurize the NMMO low-concentration solution with a mass percentage concentration of 1.1% to a pressure of 0.2MPa, and then send it into a 2-micron precision filter for precise pretreatment. Polypropylene fine filter cotton.

[0024] b. Reverse osmosis concentration: Send the filtrate in step a. under 2.5MPa pressure into the reverse osmosis membrane module for reverse osmosis concentration treatment. The operating pressure of the reverse osmosis membrane module is 2.5MPa; The reverse osmosis membrane in the module is a roll membrane, and the membrane material is polyamide material.

[0025] c. Post-processing: the concentrated water outlet in the b. step obtains a high-concentration solution of NMMO with a mass percent concentration of 8.2%, and the high-concentration NMMO solution is sent to a vacuum distillation tower for further concentrated treatment; the pure water outlet in the b. step Obtain pure water wit...

Embodiment 3

[0027] a. Pretreatment: Under the water temperature of 25°C, pressurize the NMMO low-concentration solution with a mass percentage concentration of 1.06% to a pressure of 0.2MPa, and then send it into a 2-micron precision filter for precise pretreatment, and put it into the precision filter Polypropylene fine filter cotton.

[0028] b. Reverse osmosis concentration: Send the filtrate in step a. under 2.9MPa pressure into the reverse osmosis membrane module for reverse osmosis concentration treatment. The operating pressure of the reverse osmosis membrane module is 2.5MPa; The reverse osmosis membrane in the module is a roll membrane, and the membrane material is polyamide material.

[0029] c. post-processing: the concentrated water outlet in the b. step obtains a high-concentration solution of NMMO with a mass percent concentration of 8.3%, and the pure water outlet in the b. step obtains pure water with an NMMO solvent content of 0.98%, and the pure water directly For the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com